OLED device and making method thereof, and display device

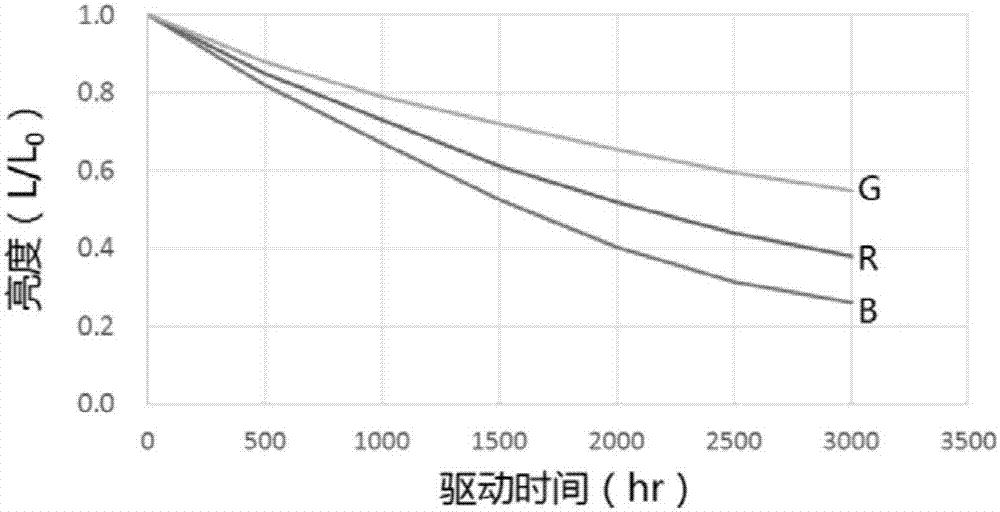

A technology for a device and a light-emitting layer, applied in the field of OLED devices and its preparation method, and display devices, can solve problems such as image color shift, achieve the effects of improving luminous brightness, preventing color shift, and reducing white point shift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment provides an OLED device, including a plurality of pixels, each pixel includes a plurality of sub-pixels of different colors, each sub-pixel includes a cathode 1, an anode 2, and a A luminous efficiency adjustment unit 4 is provided between the cathode 1 of at least some of the sub-pixels and the luminous layer 3, and the vibration characteristic peak (LSPR peak) of the luminous efficiency adjustment unit 4 can be adjusted to match the luminescent material of the corresponding luminescent layer. The wavelengths of the sub-pixels overlap so that the luminous brightness of multiple sub-pixels is consistent with the degree of attenuation over time.

[0038] In the OLED device of this embodiment, a luminous efficiency adjustment unit 4 is respectively arranged between the cathode 1 and the light-emitting layers of various colors, and a plurality of luminous efficiency adjustment units 4 are respectively adjusted so that the vibration characteristic peak of eac...

Embodiment 2

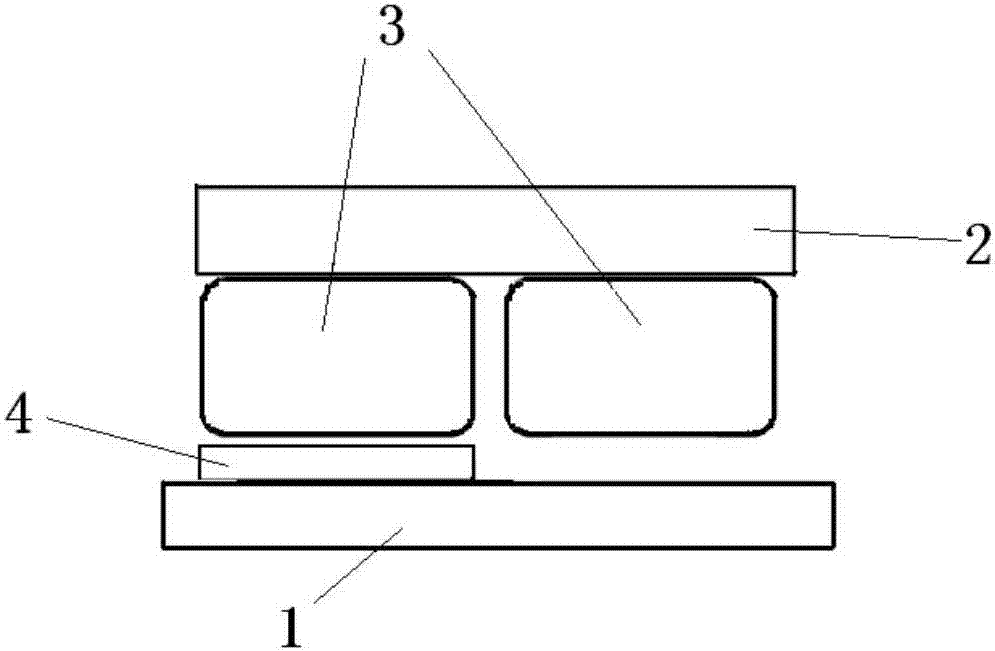

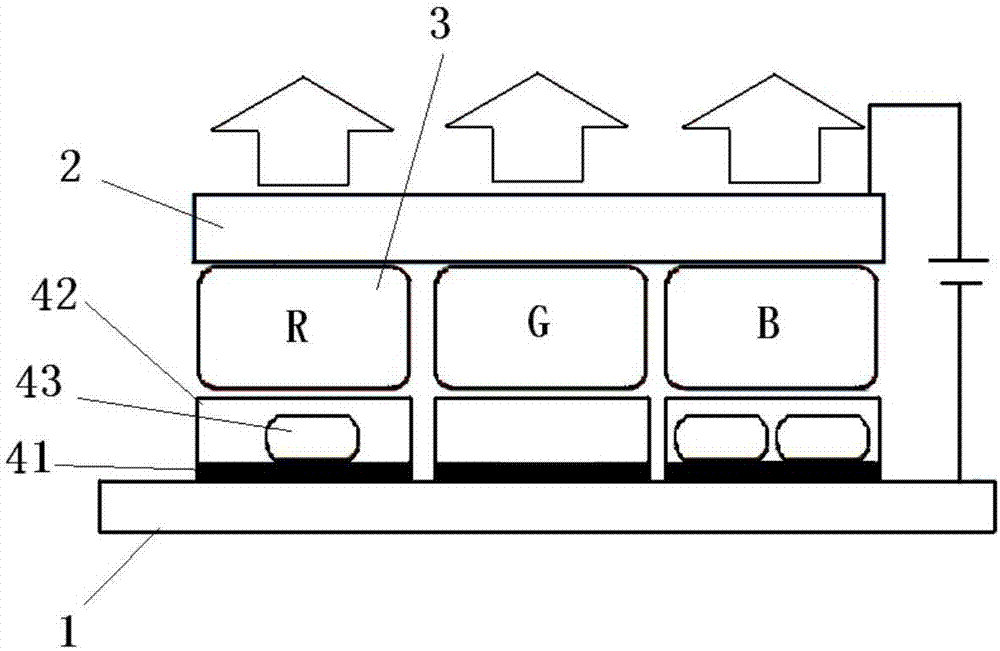

[0041] This embodiment provides an OLED device, such as figure 2 , image 3 As shown, it includes a cathode 1, an anode 2, and a light-emitting layer 3 interposed between the cathode 1 and the anode 2. The light-emitting layer 3 includes a first color light-emitting layer, a second color light-emitting layer, a second color light-emitting layer, and a light-emitting layer. A sub-pixel composed of three-color light-emitting layers, a luminous efficiency adjustment unit 4 is respectively provided between the cathode 1 and the first-color light-emitting layer and the second-color light-emitting layer, so that the first-color light-emitting layer and the second-color light-emitting layer emit light The luminous brightness of the layer and the third color luminescent layer are consistent with time decay.

[0042] That is to say, the light-emitting layer 3 includes light-emitting layers of three different colors, wherein the attenuation speed of the light-emitting brightness of th...

Embodiment 3

[0062] The present embodiment provides a kind of preparation method of above-mentioned OLED device, such as Figure 5 As shown, the following preparation steps are included:

[0063] S01. Forming a luminous efficiency adjustment unit on the cathode; which specifically includes the following preparation steps: S01a. Treating the cathode to make its surface negatively charged, and then immersing it in a charged polymer electrolyte to make its surface positively charged. Specifically, the clean ITO conductive glass is first treated with oxygen plasma to make its surface negatively charged, and then soaked in polydiallyl dimethyl ammonium chloride (PDDA) charged polymer electrolyte, polymerized The material electrolyte achieves electrostatic adsorption through the layer-by-layer self-assembly method, so that its surface is positively charged. S01b, electrostatic adsorption of silver nanorod particles on the surface of the above-mentioned cathode (i.e. ITO conductive glass), speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com