Perspiration quick-drying non-cold pajamas and its preparation process

A preparation process and quick-drying technology, applied in the field of textile fabrics, can solve the problems of perspiration, quick-drying, not catching cold, and ineffective perspiration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

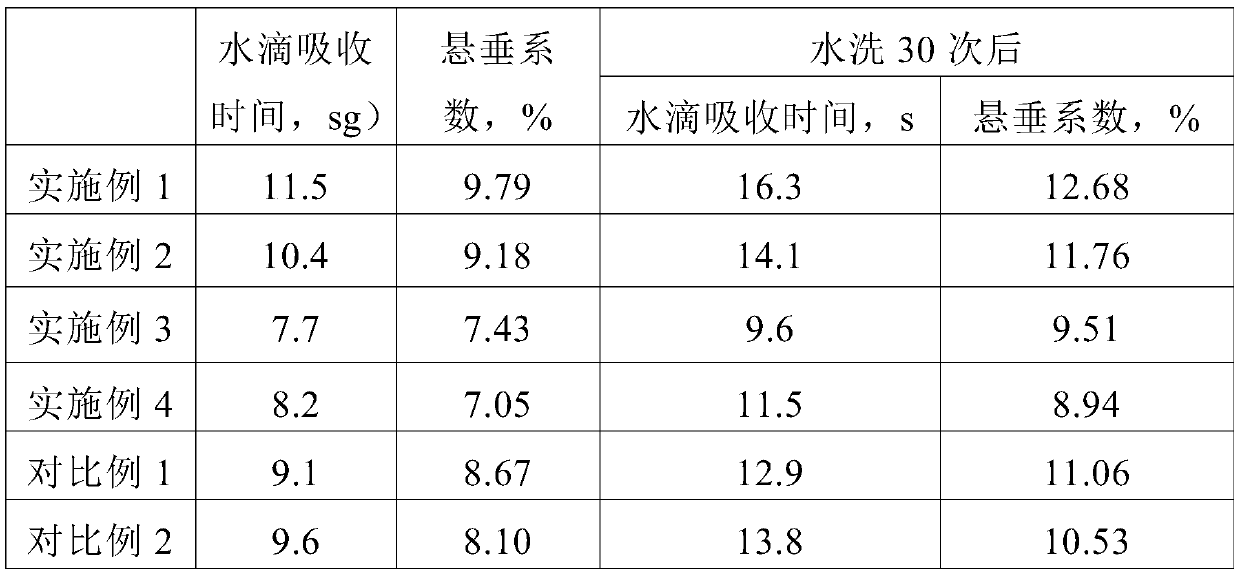

Examples

Embodiment 1

[0042] The preparation process of sweat-wicking, quick-drying and non-cold pajamas comprises the following steps:

[0043] S1: Mix polyvinyl alcohol and water uniformly at a mass ratio of 40:155 to obtain a polyvinyl alcohol emulsion. Mix 15 parts by weight of moisture-absorbing and perspiration finishing agent M-15, 10 parts by weight of polyvinyl alcohol emulsion, and 18 parts by weight of hydroxypropyl Trimethylammonium chloride chitosan is added to 1000 parts by weight of deionized water and mixed uniformly to obtain a hydrophilic finishing solution;

[0044] S2: At a temperature of 80°C, immerse the fabric in a hydrophilic finishing solution for 25 minutes, and after dehydration, dry it at a temperature of 90°C for 12 minutes to obtain a sweat-wicking, quick-drying fabric that does not catch cold;

[0045] S3: Cut the perspiration-wicking, quick-drying and non-cold fabric according to the conventional process and requirements for making pajamas, and then process it into p...

Embodiment 2

[0048] The preparation process of sweat-wicking, quick-drying and non-cold pajamas comprises the following steps:

[0049] S1: Add 15 parts by weight of moisture-absorbing and sweat-wicking finishing agent M-15, 10 parts by weight of modified polyvinyl alcohol emulsion, and 18 parts by weight of hydroxypropyltrimethylammonium chloride chitosan into 1000 parts by weight of deionized water and mix evenly. Obtain a hydrophilic finishing solution;

[0050] S2: At a temperature of 80°C, immerse the fabric in a hydrophilic finishing solution for 25 minutes, and after dehydration, dry it at a temperature of 90°C for 12 minutes to obtain a sweat-wicking, quick-drying fabric that does not catch cold;

[0051] S3: Cut the perspiration-wicking, quick-drying and non-cold fabric according to the conventional process and requirements for making pajamas, and then process it into pajamas.

[0052] Described lining is woven by following method: (1) with 38 weight parts Coolmax fiber (INVISTA ...

Embodiment 3

[0055] The preparation process of sweat-wicking, quick-drying and non-cold pajamas comprises the following steps:

[0056] S1: Add 15 parts by weight of moisture-absorbing and sweat-wicking finishing agent M-15, 10 parts by weight of modified polyvinyl alcohol emulsion, and 18 parts by weight of hydroxypropyltrimethylammonium chloride chitosan into 1000 parts by weight of deionized water and mix evenly. Obtain a hydrophilic finishing solution;

[0057] S2: At a temperature of 80°C, immerse the fabric in the hydrophilic finishing solution for 25 minutes. After dehydration, irradiate the fabric with ultraviolet light with a wavelength of 300nm for 10 minutes, and then perform microwave treatment at a microwave power of 400W and a microwave frequency of 2450MHz. 3 minutes, and then dried at a temperature of 90°C for 12 minutes to obtain a sweat-wicking, quick-drying fabric that does not catch cold;

[0058] S3: Cut the perspiration-wicking, quick-drying and non-cold fabric accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com