Preparation method of ultrathin, super-elastic, sweat-removing and warm keeping pajamas underwear fabric

A kind of underwear fabric, ultra-thin technology, applied in dyeing method, rayon manufacturing, hollow filament manufacturing and other directions, can solve the problem of easy to catch cold, prickly heat, teachers can not take care of one-to-one, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

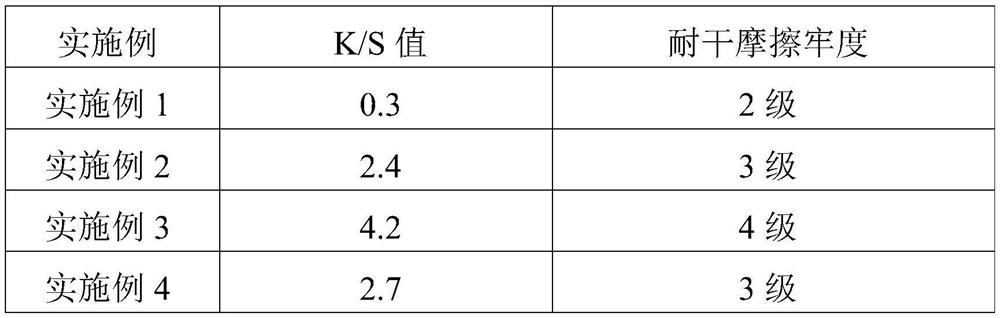

Embodiment 1

[0052] A method for preparing an ultra-thin, super-elastic, perspiration-wicking and warm-keeping pajamas underwear fabric, comprising the following steps:

[0053] S1 Add wool fiber to the oxidation treatment solution at a bath ratio of 1:20g / mL, stir at 50°C for 50 minutes, take it out, rinse it with water, and dry at 50°C for 24 hours; at a bath ratio of 1:20g / mL Add the oxidized wool to the enzyme solution, treat it at 50°C for 40 minutes, then raise the temperature to 80°C to inactivate the enzyme for 10 minutes, take it out, rinse it with water, and dry it at 50°C for 24 hours to obtain the pretreated wool ;

[0054] The preparation method of the oxidation treatment solution is as follows: 30mL of 30wt%H 2 o 2 , 4g Na 2 SiO 3 Prepared by distilling the volume to 1000mL;

[0055] The preparation method of the enzyme solution is as follows: 20 g of alkaline protease is dilute to 1000 mL with a PBS buffer solution with a pH of 9.0 and a concentration of 0.1 moL / L;

[...

Embodiment 2

[0063] A method for preparing an ultra-thin, super-elastic, perspiration-wicking and warm-keeping pajamas underwear fabric, comprising the following steps:

[0064] S1 Add the wool fiber to the reduction treatment solution at a bath ratio of 1:20g / mL, shake it at 50°C and 100rpm for 2h, take it out, rinse it with water, and dry it at 50°C for 24h; get pre-activated wool ; According to the bath ratio of 1:20g / mL, the preactivated wool was added to the biopolymer solution, shaken at 30°C and 100rpm for 18h, rinsed with water, and dried at 50°C for 24h to obtain the pretreated wool wool;

[0065] The preparation method of described reducing treatment liquid is: be that 5.0, the PBS buffer solution of concentration 0.5moL / L with pH 2.0gNaBH 4 , 15g NaHSO 3 Prepared by distilling the volume to 1000mL;

[0066] The preparation method of the biopolymer solution is as follows: 50.0 g of wheat starch is fixed to 1000 mL with a PBS buffer solution with a pH of 5.0 and a concentration...

Embodiment 3

[0073] A method for preparing an ultra-thin, super-elastic, perspiration-wicking and warm-keeping pajamas underwear fabric, comprising the following steps:

[0074] S1 Add the wool fiber to the reduction treatment solution at a bath ratio of 1:20g / mL, shake it at 50°C and 100rpm for 2h, take it out, rinse it with water, and dry it at 50°C for 24h; get pre-activated wool ; According to the bath ratio of 1:20g / mL, the preactivated wool was added to the biopolymer solution, shaken at 30°C and 100rpm for 18h, rinsed with water, and dried at 50°C for 24h to obtain the pretreated wool wool;

[0075] The preparation method of described reducing treatment liquid is: be that 5.0, the PBS buffer solution of concentration 0.5moL / L with pH 2.0gNaBH 4 , 15g NaHSO 3 Prepared by distilling the volume to 1000mL;

[0076] The preparation method of the biopolymer solution is: prepare by distilling 50.0 g of thiolated wheat starch to 1000 mL with a PBS buffer solution with a pH of 5.0 and a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com