a dental implant

A technology for implants and body parts, applied in prosthesis, dental implants, dentistry, etc., can solve problems that are not conducive to the fusion of the body and surrounding bone tissue, slow fusion of dental implants and surrounding bone tissue, and unfavorable fusion of dental implants and other problems, to achieve the effect of preventing bacteria from entering the human body, good liquid transmission effect, and not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

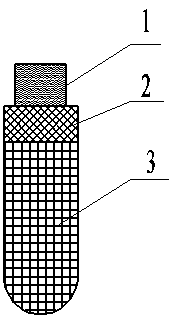

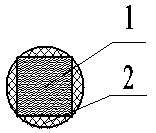

[0028] The artificial tooth implant in this embodiment is made of pure titanium. The porous material of the abutment has a pore diameter of 430nm-470nm and a porosity of 40%. The porous material of the neck has a pore diameter of 5µm-40µm and a porosity of 53%. The pore size of the porous material is 100µm-300µm, and the porosity is 58%. The pores of the three porous materials of the abutment, the neck and the body are interpenetrated respectively, and the pores of the porous material of the abutment and the porous material of the neck are interpenetrating. , the pores of the porous material of the neck and the porous material of the body are interconnected.

[0029] The preparation method of the artificial dental implant is as follows: uniformly mix pure titanium powder with a particle size of 90nm-160nm and ethyl cellulose with a particle size of 490nm-530nm according to the volume ratio of 3:2, and put them in according to the size of the abutment. In the mold prepared by s...

Embodiment 2

[0032] The artificial dental implant of this example is similar to Example 1, except that it is prepared with tricalcium phosphate, the pore diameter of the porous material of the abutment is 330nm-380 nm, the porosity is 70%, and the pore diameter of the porous material of the neck is 10µm -20µm, the pore size of the porous material in the body is 300µm-600µm.

Embodiment 3

[0034] The artificial tooth implant of this example is similar to Example 2, except that it is made of niobium, the pore diameter of the porous material of the abutment is 280nm-340nm, and the porosity is 65%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com