Method for preparing foam laminar foil by using scale effect

A scale effect, foam layer technology, applied in metal rolling and other directions, can solve problems such as difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

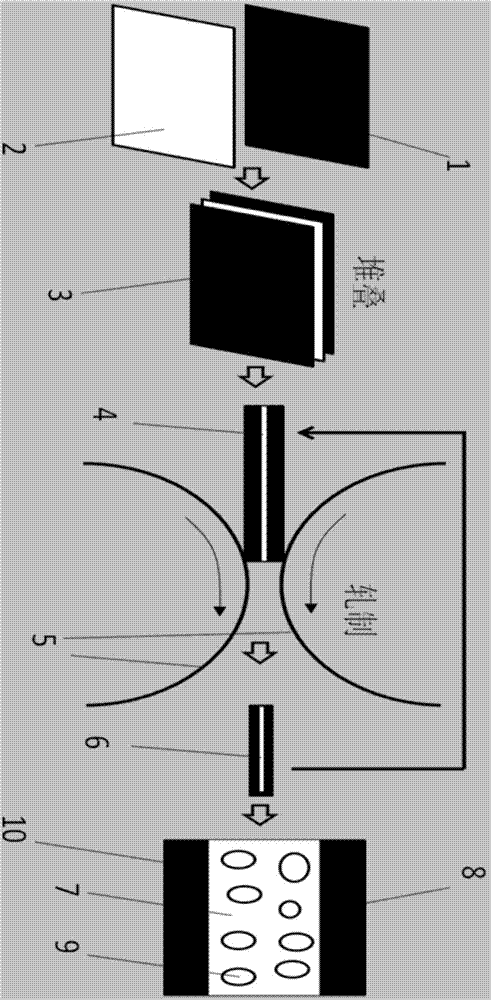

[0020] Such as figure 1 As shown, the present invention utilizes the scale effect to prepare the method for foam layered foil, and the flow process is as follows:

[0021] Step 1: Copper foil 1 and aluminum foil 2 are used as raw materials, the thickness of copper foil 1 before rolling is 100-300 μm, and the thickness of aluminum foil 2 before rolling is 15-50 μm. Aluminum foil 2 is industrial pure aluminum AA1230 foil, and copper foil 1 is common industrial copper foil.

[0022] Step 2: Process the metal aluminum foil and metal copper foil into sheets of exactly the same size.

[0023] Step 3: stacking according to copper / aluminum / copper to obtain the sheet 3, and welding the front end of the rolled piece, that is, the sheet 3, by electric welding.

[0024] Step 4: Put the welded material 4 between the upper and lower pressure rollers 5 for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com