Integrated forming processing method for hollow-out jewelry

A molding processing, hollow technology, applied in the direction of casting molding equipment, metal processing equipment, clothing, etc., can solve the problems of unsuitable industrialization promotion and application, high cost, cumbersome process, etc., to improve the overall modeling effect and quality, and low cost , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] A method for integrally forming hollow and hollow jewellery, comprising the following steps:

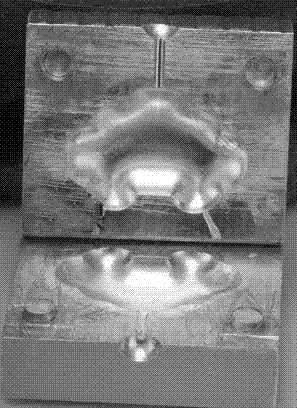

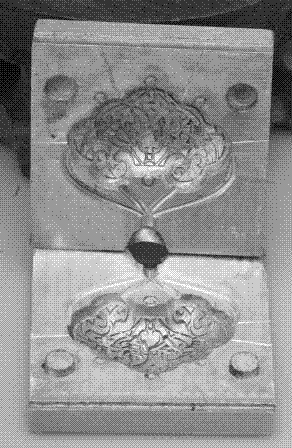

[0028] 1) Make cavity metal mold 1 and cavity metal mold 2 respectively; the shape of the cavity of cavity metal mold 1 matches the shape of the hollow inner cavity of hollow jewelry, such as figure 1 As shown; the shape of the cavity of the cavity metal mold 2 matches the shape of the hollow inner cavity of the hollow hollow jewelry, and the cavity wall of the cavity metal mold 2 has groove lines, and the overall shape of the groove lines is consistent with the shape of the hollow hollow jewelry. The hollow shape of jewelry is the same, such as figure 2 shown;

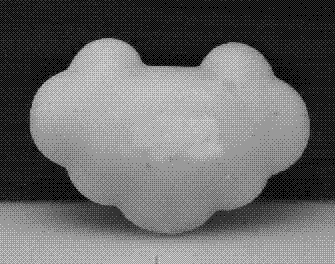

[0029] 2) Take water-soluble wax and inject it into the inner cavity of cavity metal mold 1 to form a water-soluble wax film, such as image 3 shown;

[0030] 3) Put the water-soluble wax film prepared in step 2) into the inner cavity of the cavity metal mold 2, then inject the poured wax into the cavity of the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com