Protective device and method of machine tool spindle

A protection device and a technology for the spindle of a machine tool, which is applied to the parts of the grinding machine tool, the automatic grinding control device, the grinding/polishing safety device, etc., can solve the problems of personal injury of the tool, damage to the workpiece and the spindle, and improve the processing efficiency. Precision and quality, extended service life, well-conceived effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

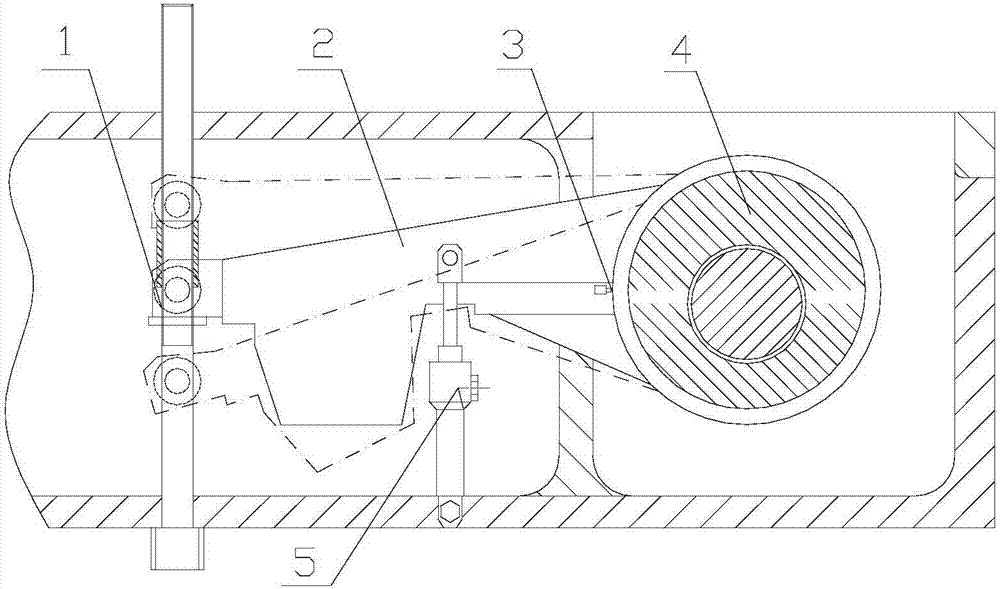

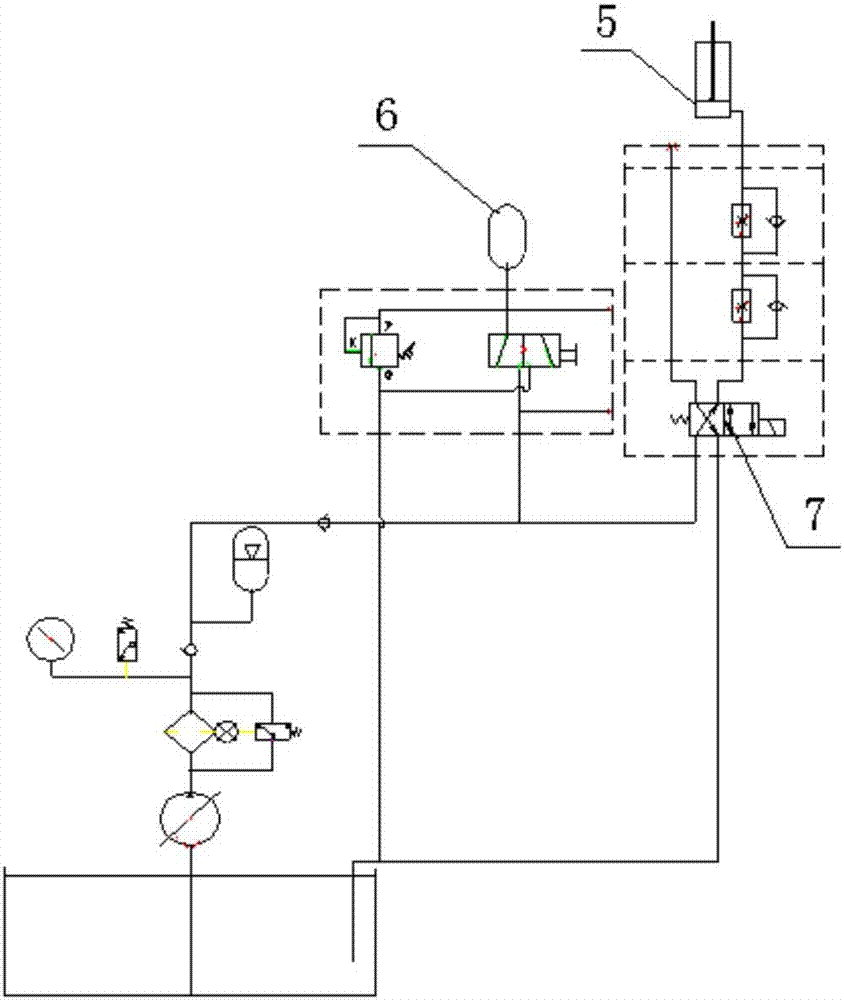

[0017] As can be seen from the accompanying drawings, the machine tool spindle protection device of the present invention includes a weight 2 connected to the eccentric sleeve transmission mechanism 1, a position detection sensor 3, a hydraulic cylinder 5, an accumulator 6, a solenoid valve 7, a hydraulic control system and a PLC, namely On the basis of the original eccentric sleeve transmission mechanism 1, weight 2 and PLC, a single-acting hydraulic cylinder 5 is connected to the weight 2, and the lower end of the hydraulic cylinder 5 is fixed on the eccentric sleeve. The hydraulic cylinder 5 is connected to the solenoid valve 7 through the hydraulic pipeline, the solenoid valve 7 is connected to the accumulator 6, and the accumulator 6 and the solenoid valve 7 are respectively connected to the hydraulic control system and the oil tank. The position detection sensor 3 is installed on the surface of the installation position of the main shaft 4, and the front end of the positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com