Abrasion-resistant integrated composite decorative timber-recombined material

A decorative material and wood technology, applied in the field of wood processing, to achieve the effects of low energy consumption, improved product quality, and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

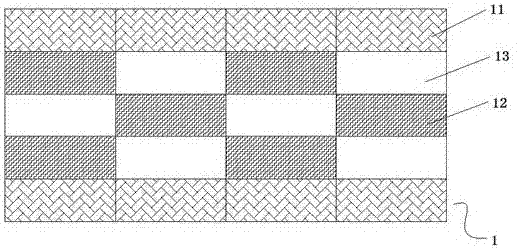

[0041] A wear-resistant wood recombined and integrated composite decorative material, comprising at least one plate structure unit, characterized in that: the plate structure unit is composed of wood edge strips arranged alternately in sequence; the wood edge strip includes a first Timber strip, second timber strip, third timber strip.

[0042] Further, the first wood edge strip is an acorn wood edge strip, and its average density is 0.55g / cm 3 .

[0043] Further, the second wood edge strip is Qi wood wood edge strip, and its average density is 0.55g / cm 3 .

[0044] Further, the third wood edge strip is catalpa wood edge strip, and its average density is 0.55g / cm 3 .

[0045] Further, the average density of the plate structural unit is 1.3g / cm 3 .

[0046] Further, the surface layer of the panel structure unit body is paved in parallel with the first wood edge strips.

[0047] Further, the wood side strips of the built-in layer of the board structure unit body are paved...

Embodiment 2

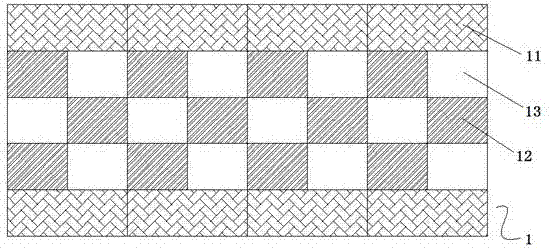

[0062] A wear-resistant wood recombined and integrated composite decorative material, comprising at least one plate structure unit, characterized in that: the plate structure unit is composed of wood edge strips arranged alternately in sequence; the wood edge strip includes a first Timber strip, second timber strip, third timber strip.

[0063] Further, the first wood edge strip is an acorn wood edge strip, and its average density is 0.8g / cm 3 .

[0064] Further, the second wood edge strip is Qi wood wood edge strip, and its average density is 0.65g / cm 3 .

[0065] Further, the third wood edge strip is catalpa wood edge strip, and its average density is 0.65g / cm 3 .

[0066] Further, the average density of the plate structural unit is 1.45g / cm 3 .

[0067] Further, the surface layer of the panel structure unit body is paved in parallel with the first wood edge strips.

[0068] Further, the wood side strips of the built-in layer of the board structure unit body are paved...

Embodiment 3

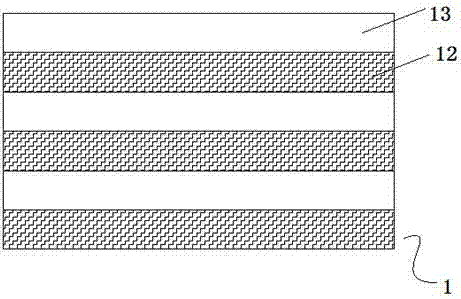

[0082] A wear-resistant wood recombined and integrated composite decorative material, comprising at least one plate structure unit, characterized in that: the plate structure unit is composed of wood edge strips arranged alternately in sequence; the wood edge strip includes a first Timber strip, second timber strip, third timber strip.

[0083] Further, the first wood edge strip is an acorn wood edge strip, and its average density is 0.65g / cm 3 .

[0084] Further, the second wood edge strip is Qi wood wood edge strip, and its average density is 0.6g / cm 3 .

[0085] Further, the third wood edge strip is a catalpa wood edge strip, and its average density is 0.6g / cm 3 .

[0086] Further, the average density of the plate structural unit is 1.35g / cm 3 .

[0087] Further, the surface layer of the panel structure unit body is paved in parallel with the first wood edge strips.

[0088] Further, the wood side strips of the built-in layer of the board structure unit body are pave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com