A kind of modified straw/polyethylene composite material and preparation method thereof

A composite material and polyethylene technology, which is applied in the field of modified straw/polyethylene composite materials and preparation, can solve the problems of poor mechanical strength and formability, difference in the interface between wood and plastic, rough product surface, etc., and achieves good anti-aging performance. , long service life and strong wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

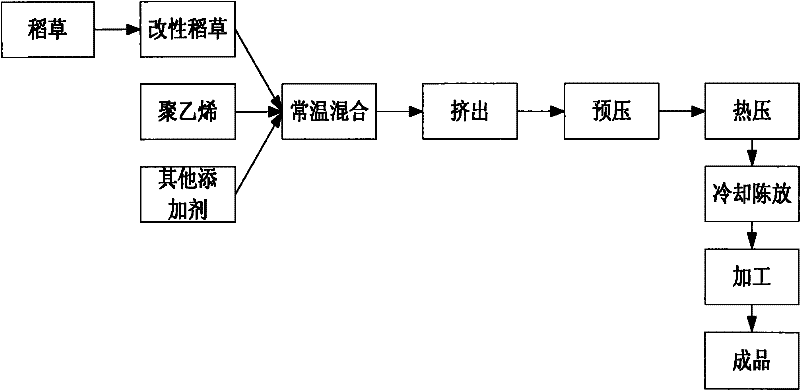

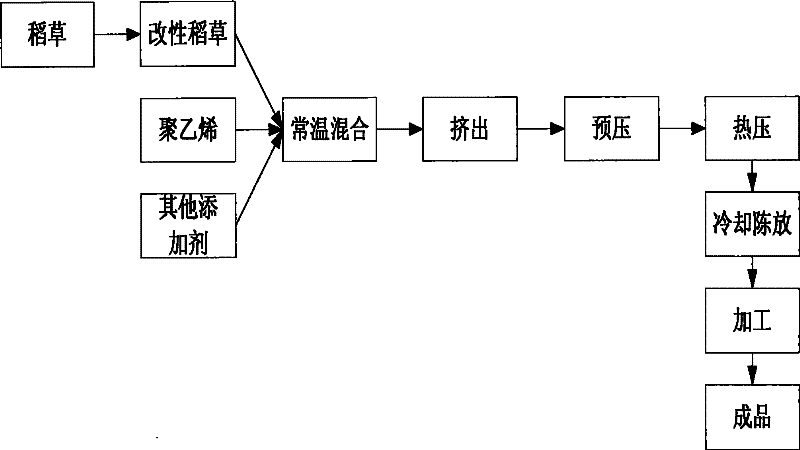

Method used

Image

Examples

Embodiment 1

[0029] 60 parts of modified straw, 25 parts of high-density polyethylene, 3.5 parts of isocyanate in acetone, 1 part of copolymer of maleic anhydride, acrylic acid and styrene, 2.5 parts of simethicone.

[0030] The preparation method is as follows: use ordinary rice straw to remove grass leaves and residual rice grains, smash them with a hay cutter, dry them, adjust the moisture content to about 5%, soak them in 2% sodium hydroxide, leave them at room temperature for 24 hours, and rinse them with distilled water , dried at 105°C for 8-10 hours, fully dried, and the moisture after drying was less than 1%, and the modified rice straw was obtained; 60 parts of modified rice straw, 25 parts of high-density polyethylene, 3.5 parts of acetone solution of isocyanate, maleic anhydride, acrylic acid , 1 part of styrene copolymer, 2.5 parts of dimethyl silicone oil. Add it into a mixer with a stirring speed of 400-500r / min, stir evenly, and extrude to granulate; the granulated particle...

Embodiment 2

[0032] 65 parts of modified straw, 27 parts of polyethylene, 4 parts of acetone solution of isocyanate, 1.5 parts of copolymer of maleic anhydride, acrylic acid and styrene, and 3 parts of paraffin wax.

[0033] The preparation method is as follows: use ordinary rice straw to remove grass leaves and residual rice grains, smash it with a hay cutter, dry it, adjust the moisture content to about 5%, soak it in 3% sodium hydroxide, leave it at room temperature for 24 hours, and rinse it with distilled water , dried at 105°C for 9 hours, fully dried, and the moisture after drying was less than 1%, and the modified rice straw was obtained; 65 parts of modified rice straw, 27 parts of polyethylene, 4 parts of acetone solution of isocyanate, maleic anhydride, acrylic acid, and styrene 1.5 parts of copolymer, 3 parts of paraffin. Add it into a mixer with a stirring speed of 400-500r / min and stir evenly, extrude and granulate; pre-press the granulated particles in a pre-pressing machine...

Embodiment 3

[0035] 70 parts of modified straw, 30 parts of polyethylene, 4 parts of acetone solution of isocyanate, 2 parts of copolymer of maleic anhydride, acrylic acid and styrene, 4 parts of polyester wax.

[0036] The preparation method is as follows: use ordinary rice straw to remove grass blades and residual rice grains, smash them with a hay cutter, dry them, adjust the moisture content to about 5%, soak them in 5% sodium hydroxide, leave them at room temperature for 24 hours, and rinse them with distilled water , dried at 105°C for 10 hours, fully dried, and after drying, the moisture content was less than 1%, and the modified rice straw was obtained; 70 parts of modified rice straw, 30 parts of polyethylene, 4 parts of acetone solution of isocyanate, maleic anhydride, acrylic acid, and styrene 2 parts of copolymer, 4 parts of polyester wax. Add it into a mixer with a stirring speed of 400-500r / min and stir evenly, extrude and granulate; pre-press the granulated particles in a pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com