Aeration device

An aeration device and reduction box technology, applied in sustainable biological treatment, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve the problems of easy deformation and damage of impeller blades, increase of production cost, waste of manpower, etc. , to achieve the effect of convenient disassembly and maintenance, prolonging the service life and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

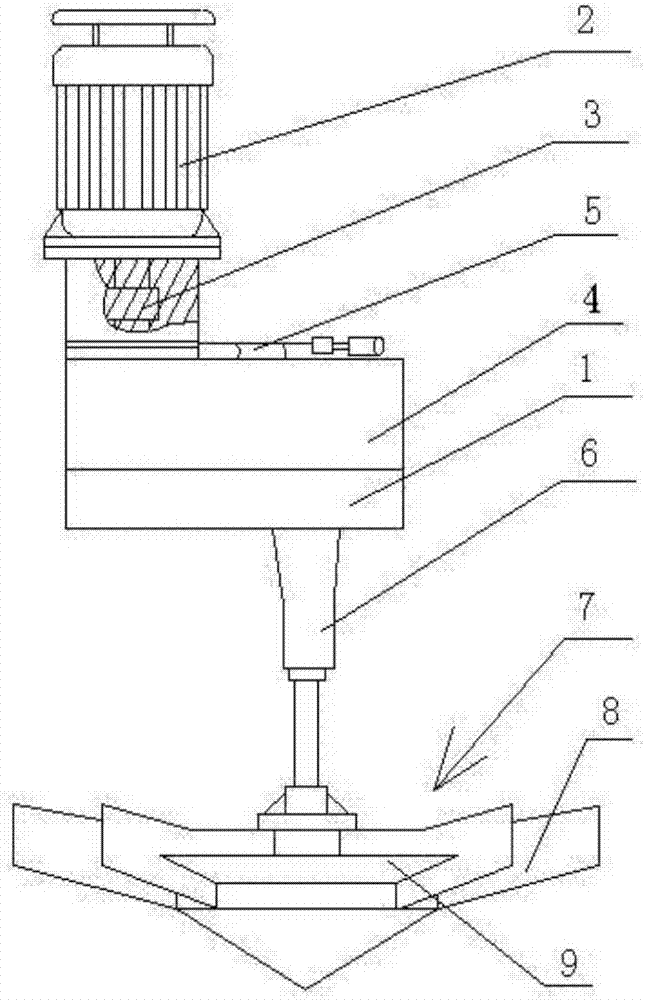

[0016] see figure 1 As shown, the present invention relates to an aeration device, comprising a frame 1, a motor 2, a shaft coupling 3, a reduction box 4, a lubricating oil passage 5, an inverted umbrella seat 6 and an impeller 7; the frame 1 is provided with a reduction box 4. The reduction box 4 is connected to the motor 2 through the coupling 3. The motor 2 is installed on the reduction box 4 and is not easily corroded by splashed sewage. It occupies a small area and is very convenient for disassembly and maintenance. There is a lubricating oil passage 5, and an oil hole is added between the bearings of the reduction box 4, and the lubricating oil passage 5 communicates with the oil hole between the bearings of the reduction box 4, so that the lubricating oil can be passed to the bearing of the reduction box 4, and the impeller The shaft of 7 is connected to the output end of the reduction box 4 through the inverted umbrella seat 6. The impeller 7 includes a number of impel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com