Double-layer PP-R pipe

A PP-R, pipe technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of algae pollution, easy blockage, short life, etc. The effect of reducing manufacturing cost and usage cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the embodiments in the accompanying drawings, but this does not constitute any limitation to the present invention.

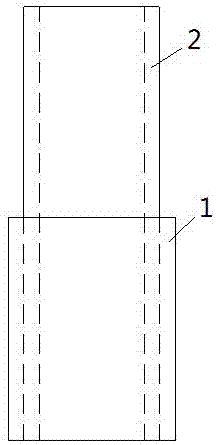

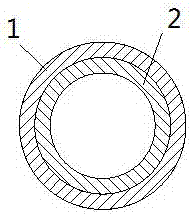

[0026] Such as figure 1 with figure 2 As shown, a double-layer PP-R pipe provided by the present invention includes a PP-R anti-ultraviolet outer layer 1 and a PP-R inner layer 2, and the inner and outer layers are co-extruded into an integrated structure.

[0027] The PP-R anti-ultraviolet outer layer 1 is composed of 85-96% of PP-R resin, 2-4% of light-blocking color masterbatch, 1-5% of nano-carbon fiber masterbatch, and 0.5-2% of ultraviolet absorber in terms of mass percentage. %, antioxidant 0.3-4%, wherein, the ultraviolet absorber is ultraviolet absorber UV-531, and the antioxidant is antioxidant 1010.

[0028] The proportioning ratio of each component in the PP-R anti-ultraviolet outer layer is shown in Table 1.

[0029] Table 1

[0030] Components ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com