Modular cell culture and transportation assembly

A cell culture and modular technology, applied in the field of biological devices, can solve the problems of different technical and operational levels, difficulty in unifying and improving the quality and effect of cell therapy, and limiting the promotion and application of cell therapy technology, etc., to achieve a solution Effect of cell contamination, reduction of risk of cell contamination, solution to transport issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

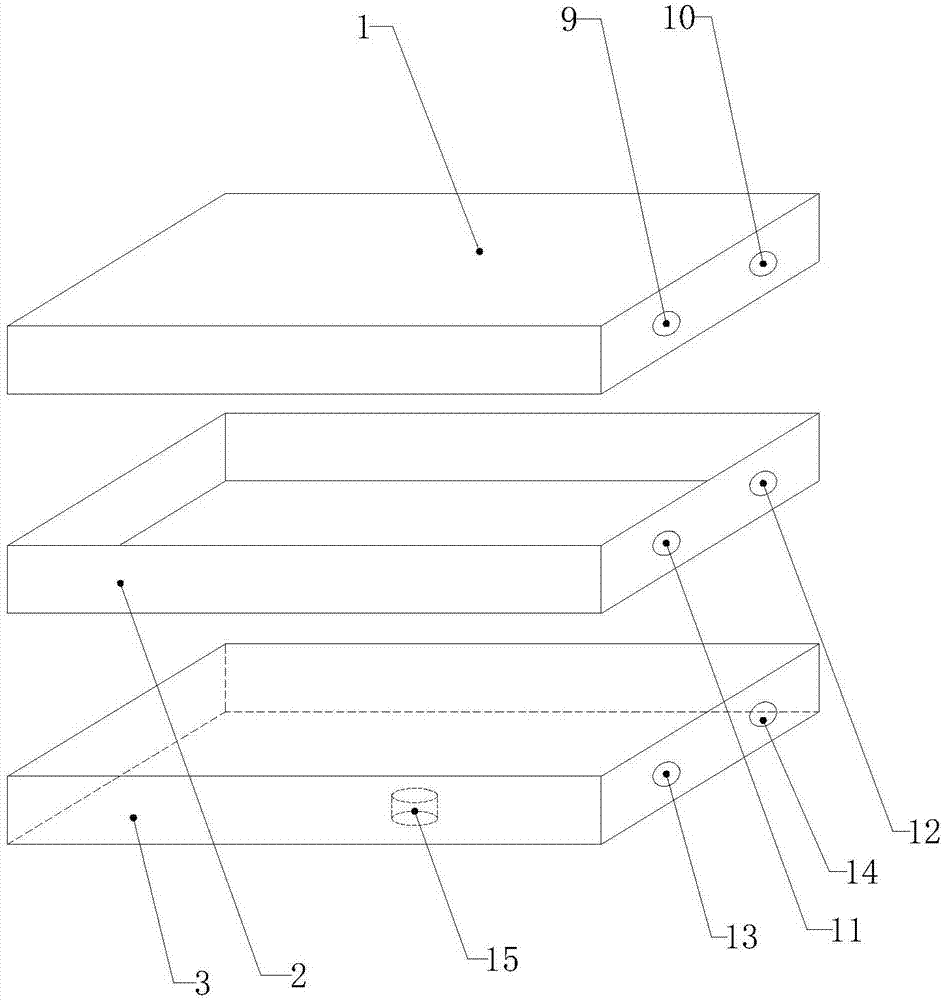

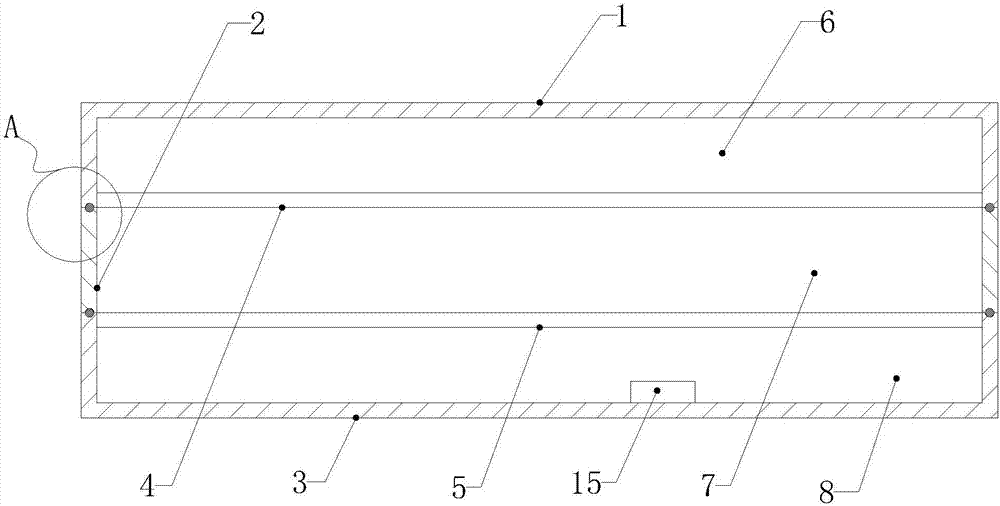

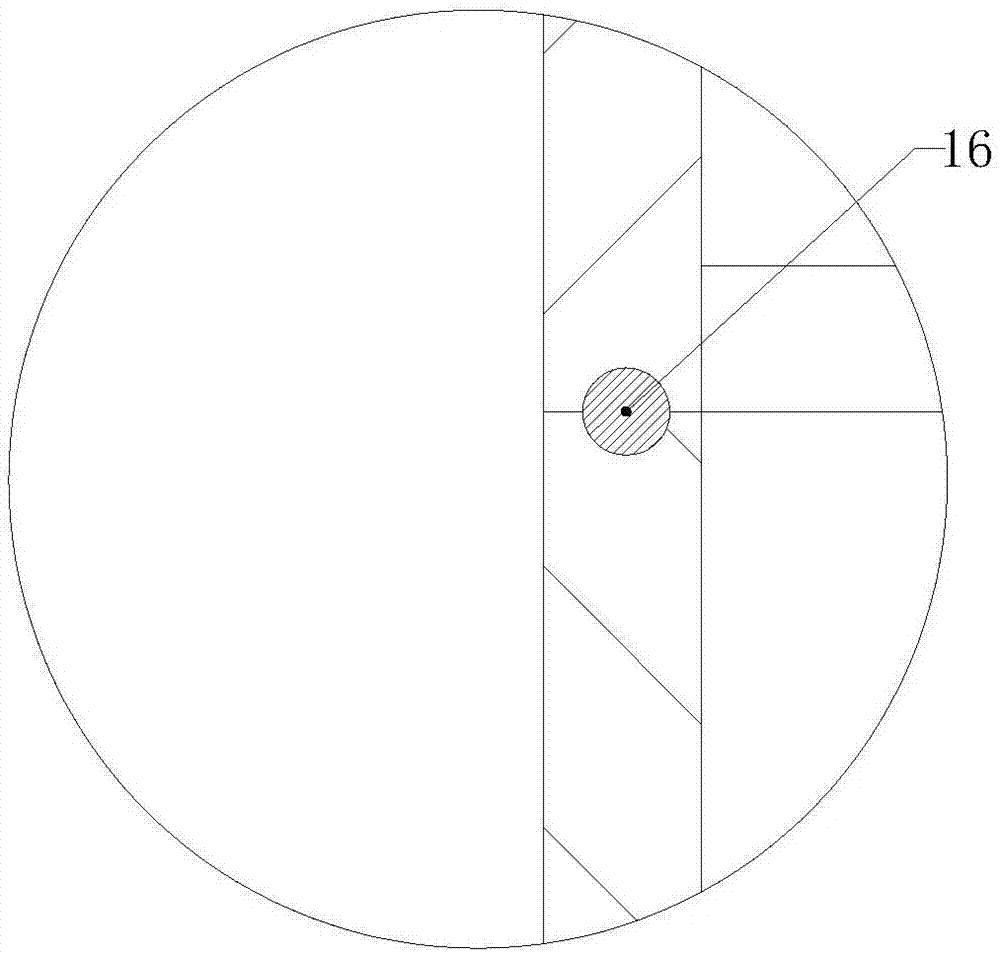

[0041] see Figure 1 to Figure 4 , a modular cell culture and transport assembly according to a preferred embodiment of the present invention, comprising a top cover 1, a connection frame 2 positioned below the top cover, a bottom cover 3 positioned below the connection frame, and the top cover is a box with the opening downward The connection frame is a rectangular frame body, the bottom cover is a box-like structure with an opening upward, a breathable film 4 is arranged between the top cover and the connection frame, and the edge of the breathable film is fixedly arranged on the inner side of the top cover. A water-permeable membrane 5 is arranged between the bottom covers, and the edge of the water-permeable membrane is fixedly arranged on the inner side of the bottom cover. A cell culture chamber 7 for culturing cells, surrounded by a water-permeable membrane and a bottom cover to form a culture medium chamber 8 for storing culture fluid, the side wall of the top cover is...

Embodiment 2

[0048] see Figure 5 and Figure 6 , the structure of this embodiment is basically the same as that of the modular cell culture and transport assembly in Embodiment 1, slots are respectively provided on the upper surface and the lower surface of the connection frame, and slots are respectively provided on the lower surface of the top cover and the upper surface of the bottom cover. There is a positioning plate 17 adapted to the slot. The left and right sides of the bottom cover are respectively provided with connecting plates 18, the bottom ends of the connecting plates are hinged on the outer surfaces of the bottom cover, and the top ends of the connecting plates are detachably connected with the top cover. A positioning groove 19 is provided on the outer surface of the top cover, and a locking bolt 20 threadedly connected with the positioning groove is provided on the connecting plate. A first handle 21 is hinged on the outer surface of the connecting plate. A second hand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com