Method for preparing cylindrical concrete pier column

A concrete pier, cylindrical technology, applied in the direction of bridge parts, bridges, buildings, etc., can solve the problems of construction joints, long construction period, affecting the quality and appearance of the pier body, etc., to improve the connection tightness, engineering quality assurance, Demolition cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A method for manufacturing cylindrical concrete piers, the innovation is that: the method includes:

[0020] 1) Make the platform;

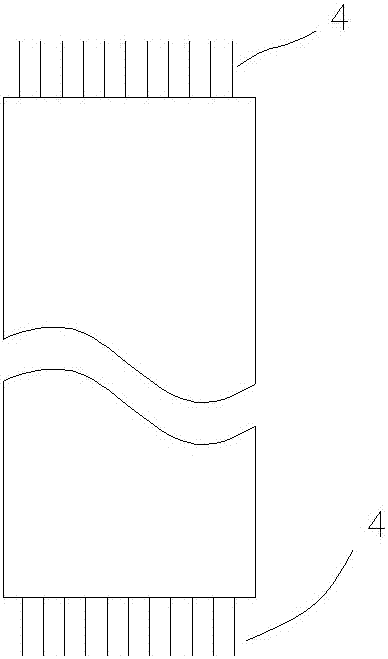

[0021] 2) Connect the lower end of the disassembly-free template with the upper end of the bearing platform;

[0022] 3) Build pier core steel bars in the space enclosed by the platform and the free disassembly template;

[0023] 4) Pour concrete into the inner hole of the dismantling-free formwork. After the concrete is solidified, the cylindrical concrete pier is completed. The dismantling-free formwork forms the outer structure of the cylindrical concrete pier;

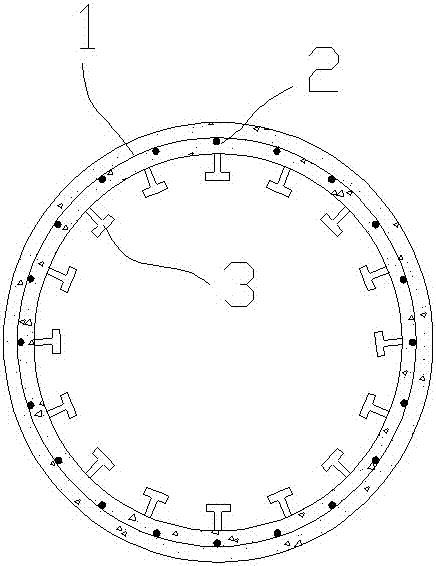

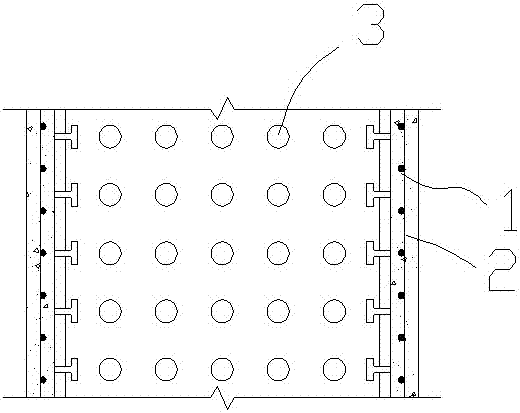

[0024] The disassembly-free template is composed of a steel frame, a plurality of studs and a concrete cladding; the steel frame is a cylindrical structure, the concrete cladding wraps the steel frame, and the steel frame and the concrete cladding form a cylindrical shape The reinforced concrete structure; one end of the stud is fixedly connected to the steel frame, the other end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com