A pipeline robot for detection and cleaning of boiler headers in power plants

A technology for pipeline robots and power station boilers, which is applied to pipe components, special pipes, mechanical equipment, etc., can solve the problems that the detection device cannot meet the cleanliness inspection, there is no boiler header foreign matter removal device, and there are few pipeline cleaning robots. Good barrier performance, simple structure, and the effect of reducing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings.

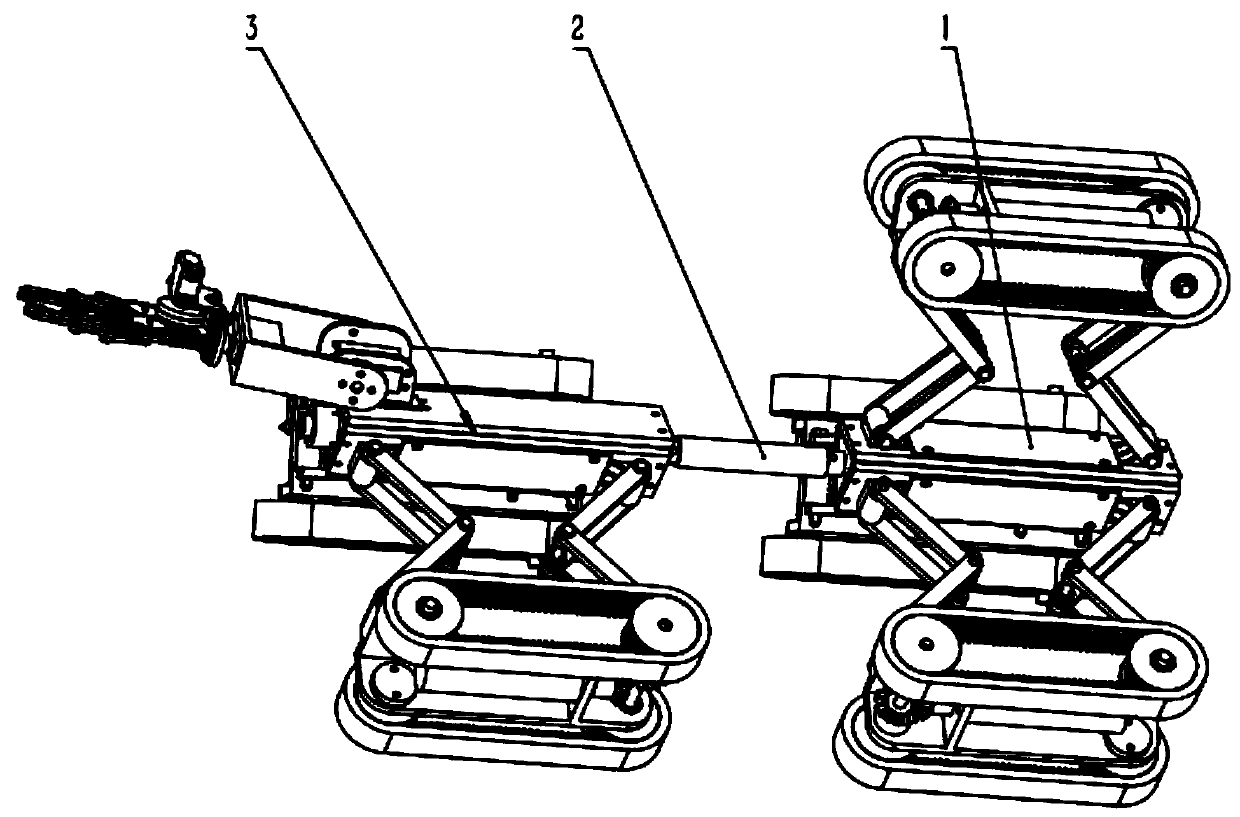

[0028] see figure 1 , the pipeline robot of the present invention includes a walking module 1 , a universal joint 2 and a cleaning module 3 , and the walking module 1 and the cleaning module 3 are connected through the universal joint 2 . Specifically, the pipeline robot is provided with an extension shaft on the side corresponding to the walking module 1 and the cleaning module 3, respectively, and the two ends of the universal joint 2 are respectively fixed on the extension shaft. When the pipeline robot used for the detection and cleaning of the boiler header of the power station passes through the bend, the universal joint 2 plays the role of a flexible connection.

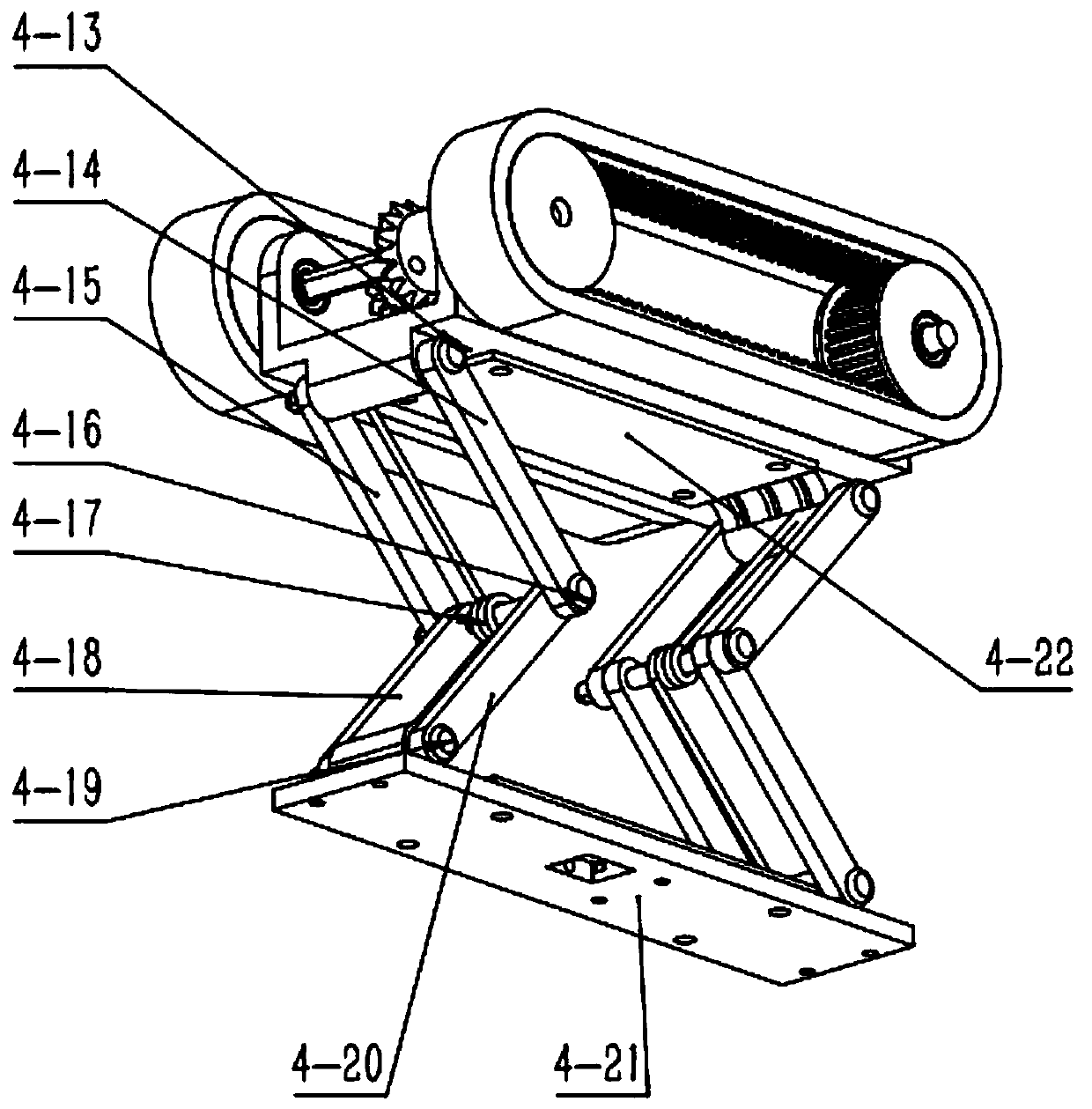

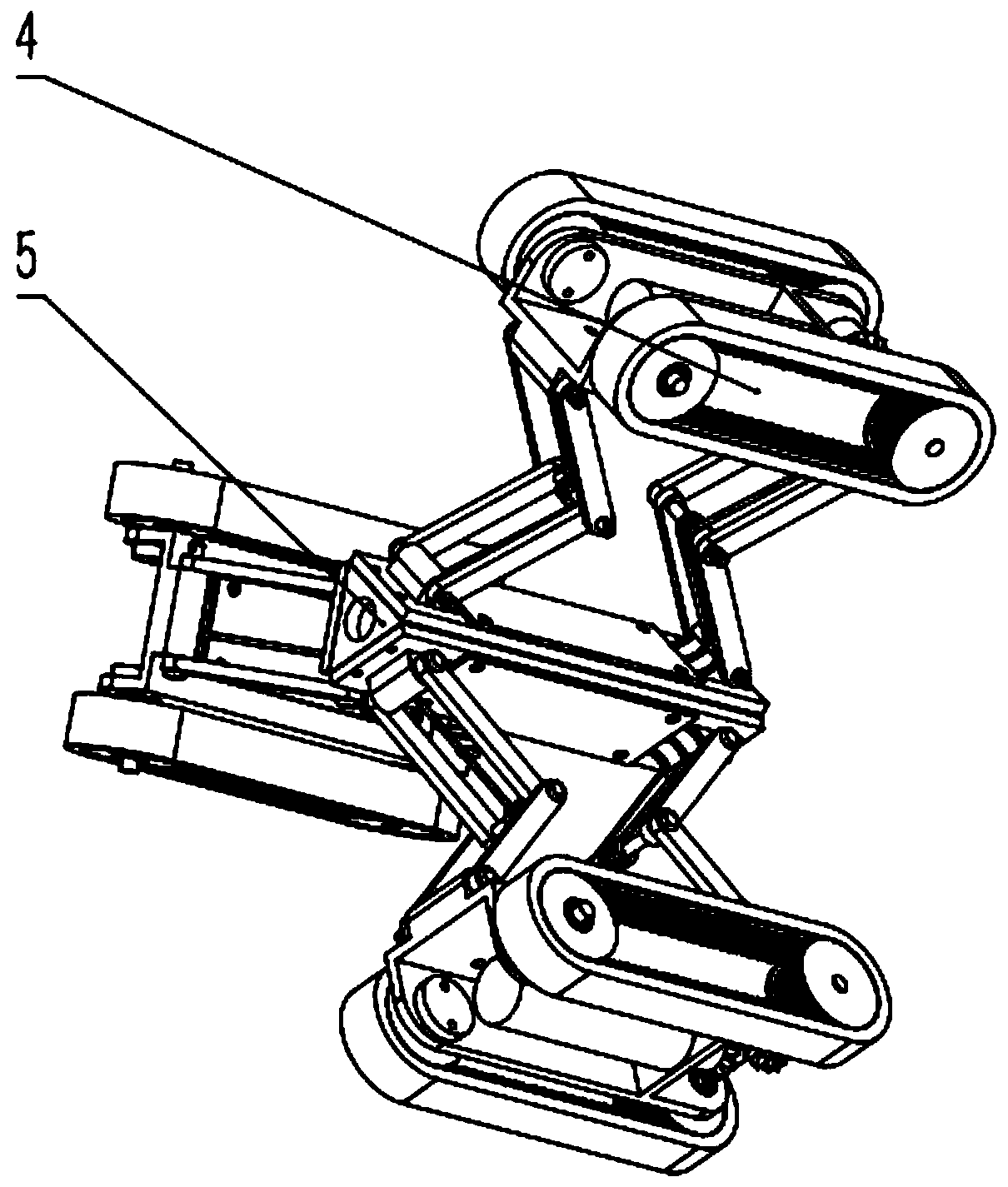

[0029] see figure 2 , the walking module 1 of the pipeline robot of the present invention has three groups of first walking units 4, and the three groups of walking units are evenly distri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com