Refrigerant flow control method of water chilling unit

A technology for a chiller and a control method, which is applied to refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve problems such as low performance, and achieve the effect of improving load heat transfer efficiency and reducing the risk of liquid carrying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

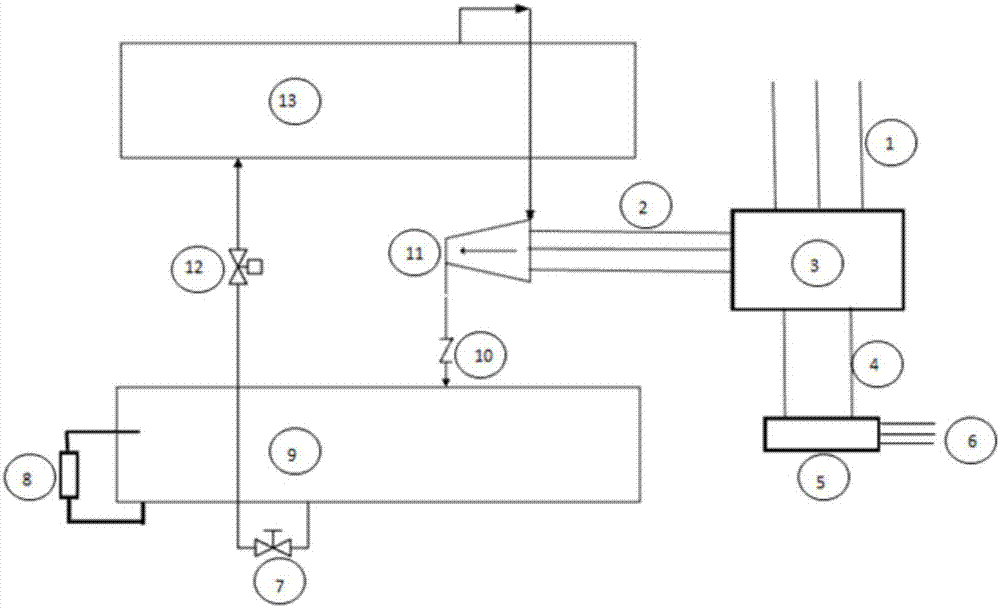

[0034] The structure of the chiller system used in the chiller refrigerant flow control method implemented according to the present invention is as follows: figure 1 As shown, it mainly includes a condenser 9, an evaporator 13, a compressor 11, and a micro-control cabinet 5 equipped with a controller. , the compressor 11 is connected to the evaporator 13, and the compressor 11 is connected to the condenser 9 through the exhaust check valve 10; Connection, the starter cabinet 3 is connected to the signal of the micro-control cabinet 5 through the communication line 4 between the starter cabinet and the micro-control cabinet, and the micro-control cabinet 5 is connected to each sensor and valve control element through the communication line 6 between the micro-control cabinet and the electrical parts of the unit signal connection. The main throttling device is the electronic expansion valve 12 .

[0035]It is not shown in the figure but those skilled in the art should be clear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com