Method for predicting corrosion lifetime of casing pipe

A technology of life prediction and casing, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problem of not truly reflecting the corrosion life of the casing, and achieve the effect of accurate life and avoiding safety risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

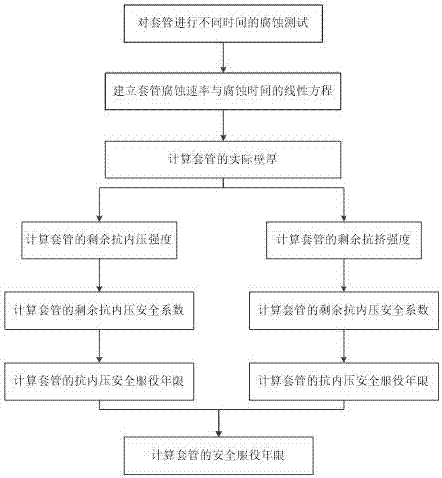

[0050] figure 1 A flow chart of a casing corrosion life prediction method is given.

[0051] Step 1: According to the service environment of the oil and gas well casing, use a high-temperature autoclave to simulate the actual working conditions to conduct a corrosion test on the casing material, and the test time is n=[X 1 ,X 2 ,X 3 ,…X i ,…X n ], n represents the length of the test time, X i = 3d, 7d, 15d, 30d, 90d and 180d, and use the corrosion rate formula (1) to obtain the uniform corrosion rate value of the material respectively;

[0052]

[0053] In the formula: v cor is the measured corrosion rate (mm / a), Δm is the mass difference (g) of the sample before and after the corrosion test, ρ is the sample density (g / cm), A is the sample surface area (cm 2 ), n is the corrosion time (d);

[0054] Step 2: Perform multiple linear ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com