Physical method for separating electrode current collector from electrode material of lithium ion battery

A lithium-ion battery, electrode current collector technology, applied in battery recycling, waste collector recycling, recycling technology and other directions, can solve problems such as high cost, unsuitable for large-scale recycling requirements, environmental pollution, etc., and achieve high recycling rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

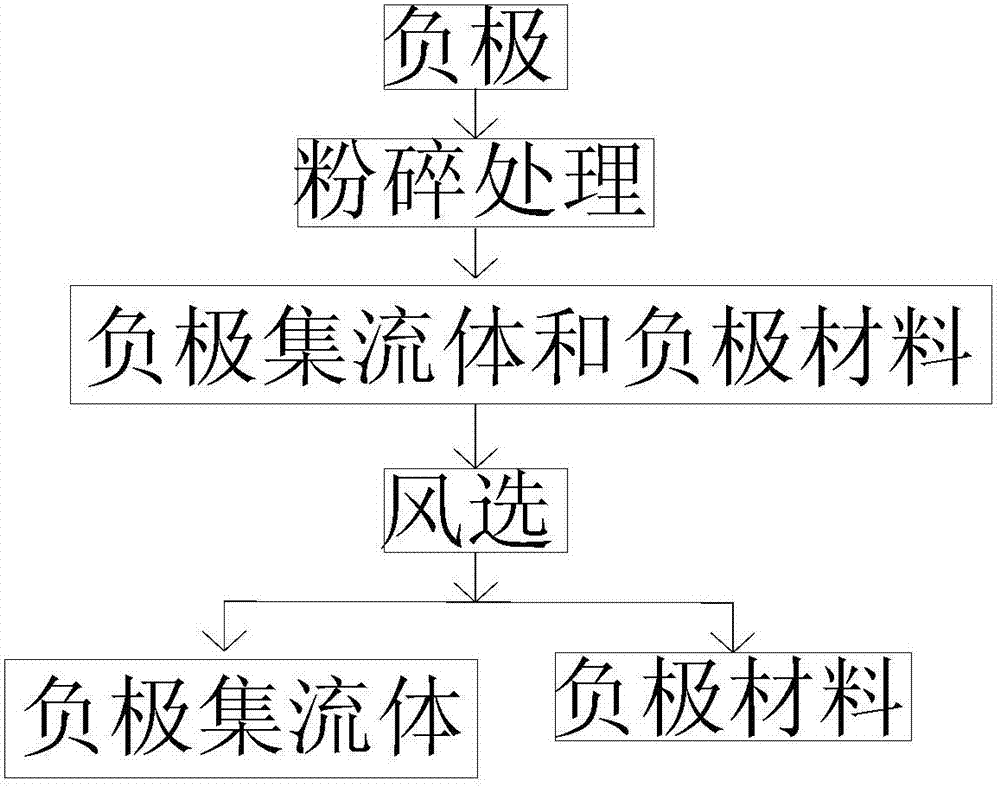

[0023] refer to figure 1 , the technical process of the physical method for separating the lithium-ion battery negative electrode provided by this implementation is as follows:

[0024] First, put the anode produced from production or separated from the waste lithium-ion battery into a pulverizer for pulverization, and through the pulverization process, the anode material bonded together is separated from the anode current collector, so that the anode material can be separated from the The negative electrode collector is detached from the body;

[0025] Then, the crushed negative electrode current collector and negative electrode material are subjected to air separation; since the specific gravity of the negative electrode current collector is larger than that of the negative electrode material, the negative electrode current collector can be separated from the negative electrode material by wind separation, and the negative electrode current collector and negative electrode a...

Embodiment 2

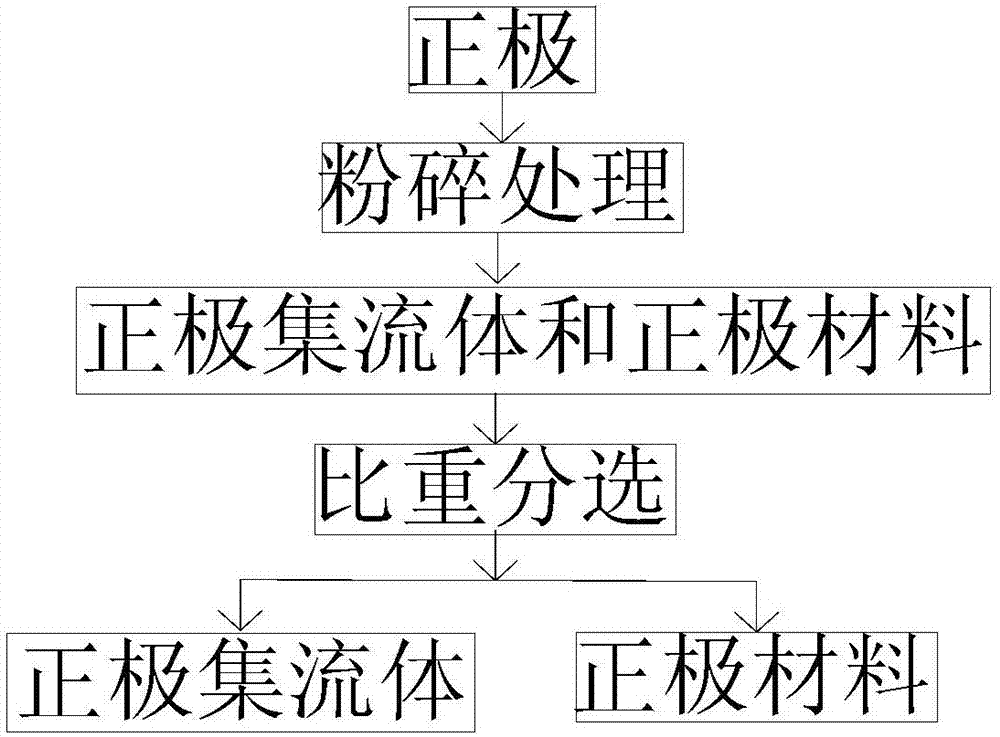

[0027] refer to figure 2 , the process flow of the physical method for separating the positive electrode of the lithium-ion battery provided in this embodiment is as follows:

[0028] First, put the positive electrode generated from production or separated from the waste lithium-ion battery into a pulverizer for crushing, and the positive electrode material is separated from the positive electrode current collector through the crushing process, so that the positive electrode material is separated from the positive electrode current collector. down;

[0029] Then, the pulverized positive electrode current collector and positive electrode material are subjected to specific gravity sorting; since the specific gravity of the positive electrode current collector is larger than that of the positive electrode material, when the specific gravity of the solution used for specific gravity sorting is greater than the positive electrode material and smaller than the positive electrode cu...

Embodiment 3

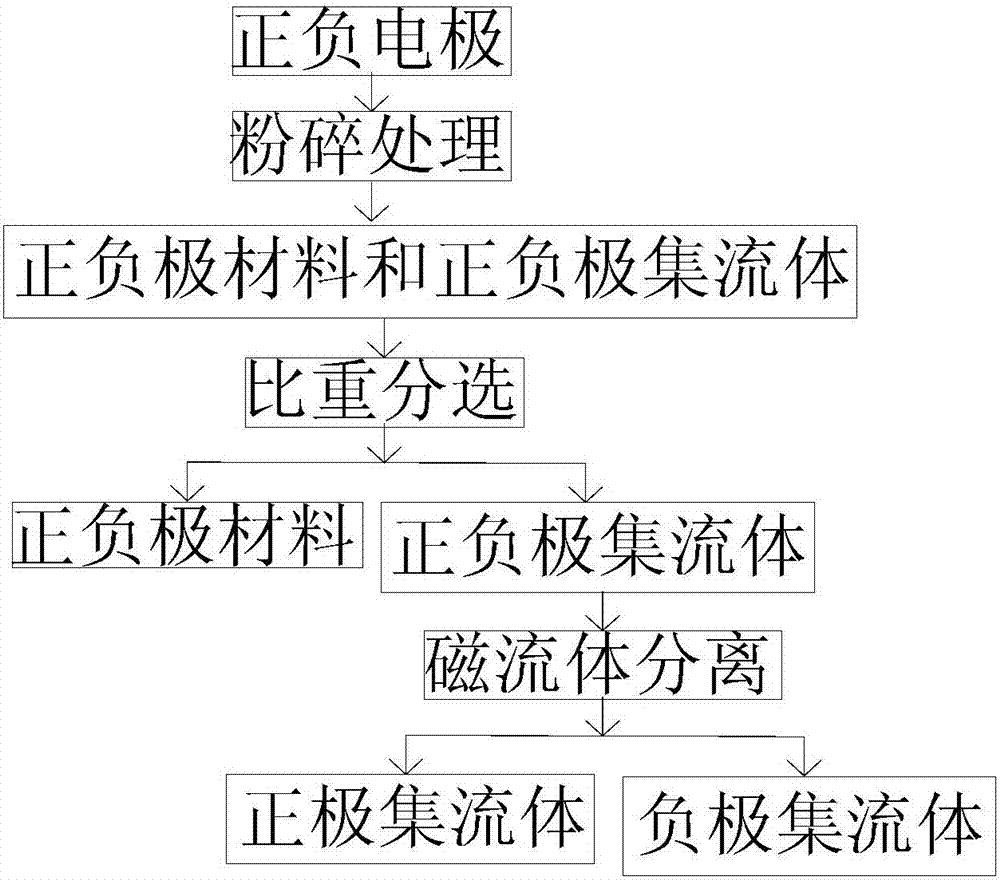

[0031] refer to image 3 The process flow of the physical method for separating the positive and negative electrodes of lithium-ion batteries provided in this embodiment is as follows:

[0032] First of all, the positive and negative electrodes produced in production or separated from waste lithium-ion batteries are put into the pulverization device, and the positive and negative electrodes are pulverized, and the positive electrode material is separated from the positive electrode current collector through pulverization, and the negative electrode material and Negative electrode current collectors are phase-separated to obtain positive and negative electrode materials and positive and negative electrode current collectors, so that the positive and negative electrode materials are separated from the positive and negative electrode current collectors;

[0033] Then, the pulverized positive and negative electrode materials and the positive and negative electrode current collecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com