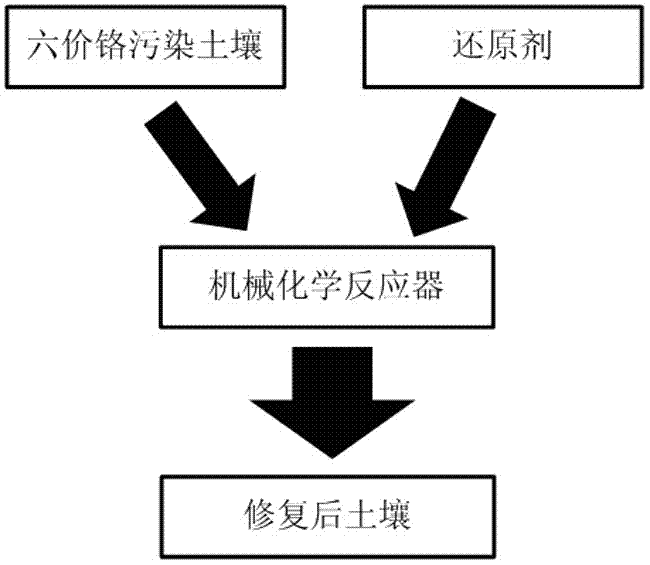

Mechanochemical reduction remediation method for hexavalent chromium polluted soil

A technology of mechanochemistry and remediation methods, which is applied in the restoration of polluted soil and other directions to achieve the effect of enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] After mixing 10g of contaminated soil (the content of hexavalent chromium in the original soil sample is 2360 mg / kg, according to GB 5085.3-2007, the leaching concentration of hexavalent chromium is 22.58 mg / L) with 0.2g of ferrous sulfate and 0.1g of calcium polysulfide Add it into the planetary ball mill tank, and then add zirconia grinding balls to the ball mill tank, wherein the mass ratio of material to grinding balls is 1:9. The operating conditions of the ball mill are set as follows: the ball milling speed is 500 rpm, the ball milling time is 2 hours, the ball milling method is 15 minutes, and the interval is 15 minutes, and the cycle is carried out sequentially. After the mechanochemical reaction, samples were taken for toxicity leaching experiments, and the leaching concentration of hexavalent chromium in the leach solution was measured.

[0021] After analysis, the concentration of hexavalent chromium in the leachate was 0.92 mg / L, which was lower than the st...

Embodiment 2

[0023] Mix 10g of contaminated soil (the content of hexavalent chromium in the original soil sample is 2360 mg / kg, and the leaching concentration of hexavalent chromium is 22.58 mg / L according to GB 5085.3-2007) and 0.3 g of ferrous sulfate are added to the tank of the planetary ball mill , and then add zirconia grinding balls to the ball mill jar, wherein the mass ratio of the material to the grinding balls is 1:9. The operating conditions of the ball mill are set as follows: the ball milling speed is 600 rpm, the ball milling time is 2 hours, the ball milling method is 15 minutes, and the interval is 15 minutes, and the cycle is carried out sequentially. After the mechanochemical reaction, samples were taken for toxicity leaching experiments, and the leaching concentration of hexavalent chromium in the leaching solution was measured.

[0024] After analysis, the concentration of hexavalent chromium in the leachate was 0.38 mg / L, which was lower than the standard value for le...

Embodiment 3

[0026] Mix 10g of contaminated soil (the content of hexavalent chromium in the original soil sample is 2360 mg / kg, and the leaching concentration of hexavalent chromium is 22.58 mg / L according to GB 5085.3-2007) and 0.3 g of calcium polysulfide are added to the tank of the planetary ball mill , and then add zirconia grinding balls to the ball mill jar, wherein the mass ratio of the material to the grinding balls is 1:9. The operating conditions of the ball mill are set as follows: the ball milling speed is 500 rpm, the ball milling time is 2 hours, the ball milling method is 15 minutes, and the interval is 15 minutes, and the cycle is carried out sequentially. After the mechanochemical reaction, samples were taken for toxicity leaching experiments, and the leaching concentration of hexavalent chromium in the leach solution was measured.

[0027] After analysis, the concentration of hexavalent chromium in the leachate was 0.51 mg / L, which was lower than the identification stand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com