A flexible cable fixed-length cutting machine

A flexible cable and shearing machine technology, applied in the field of flexible cable fixed-length shearing machines, can solve the problems of low processing efficiency, low processing accuracy, and high labor costs, and achieve reduced labor costs, simple structure, and improved processing accuracy. The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

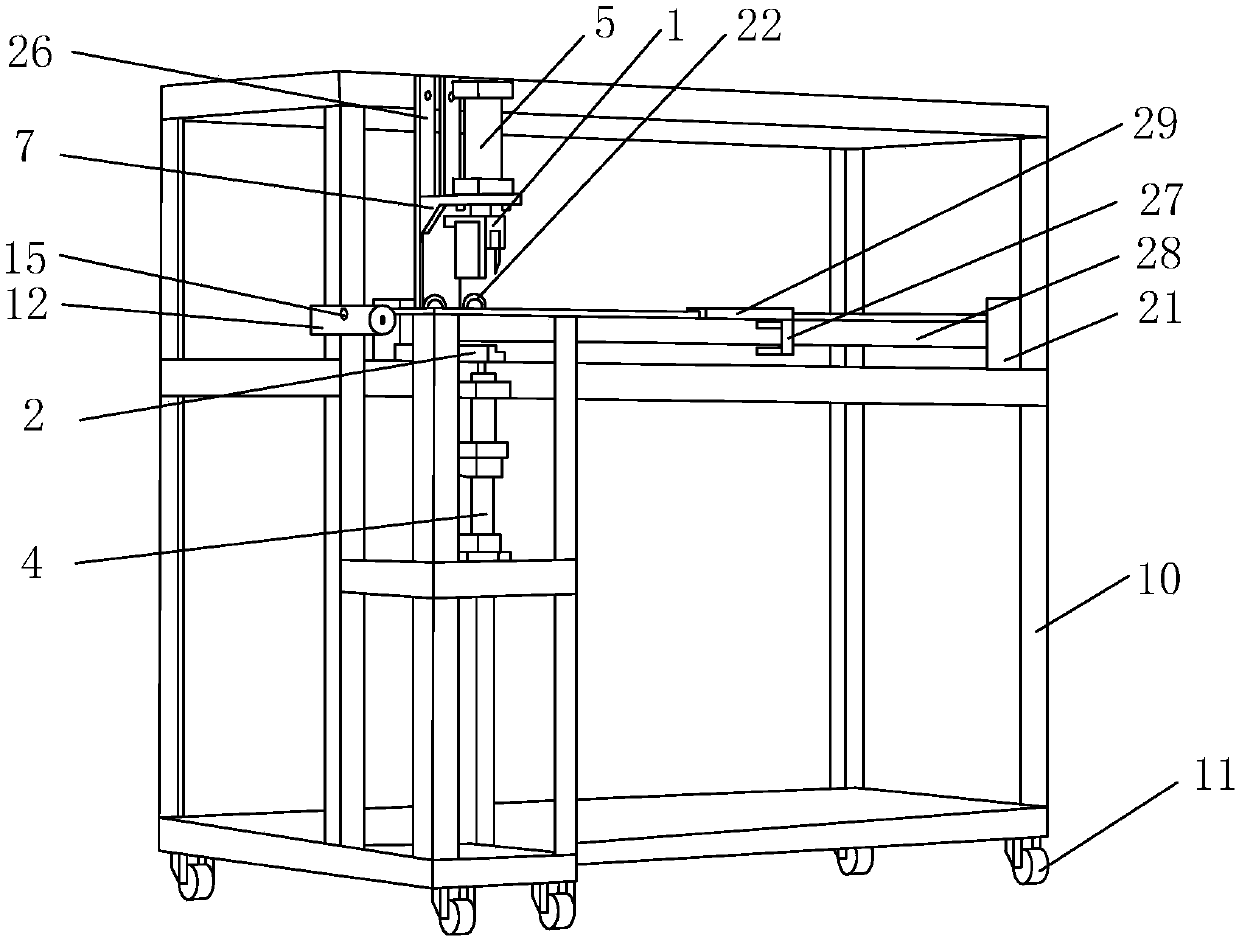

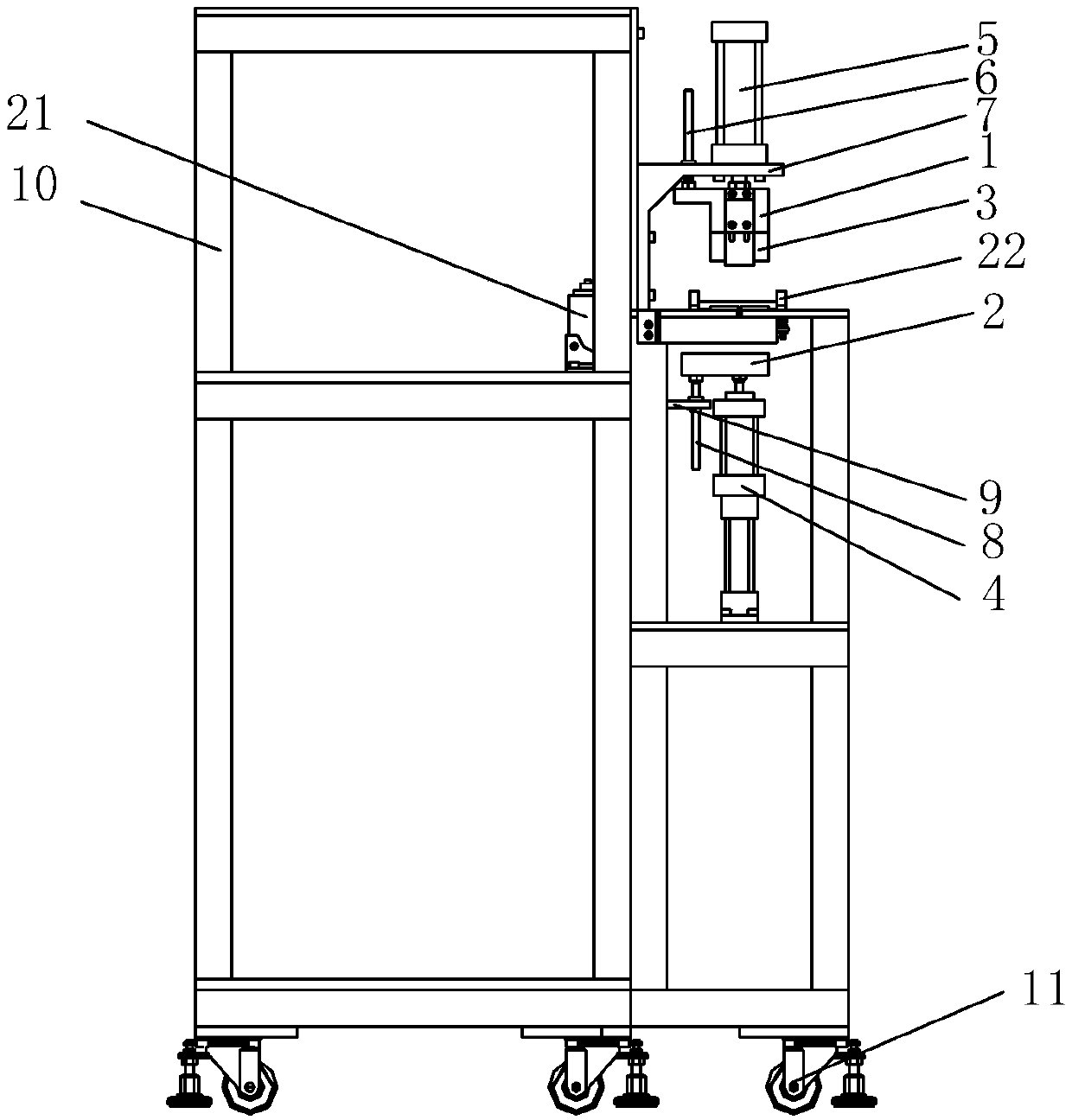

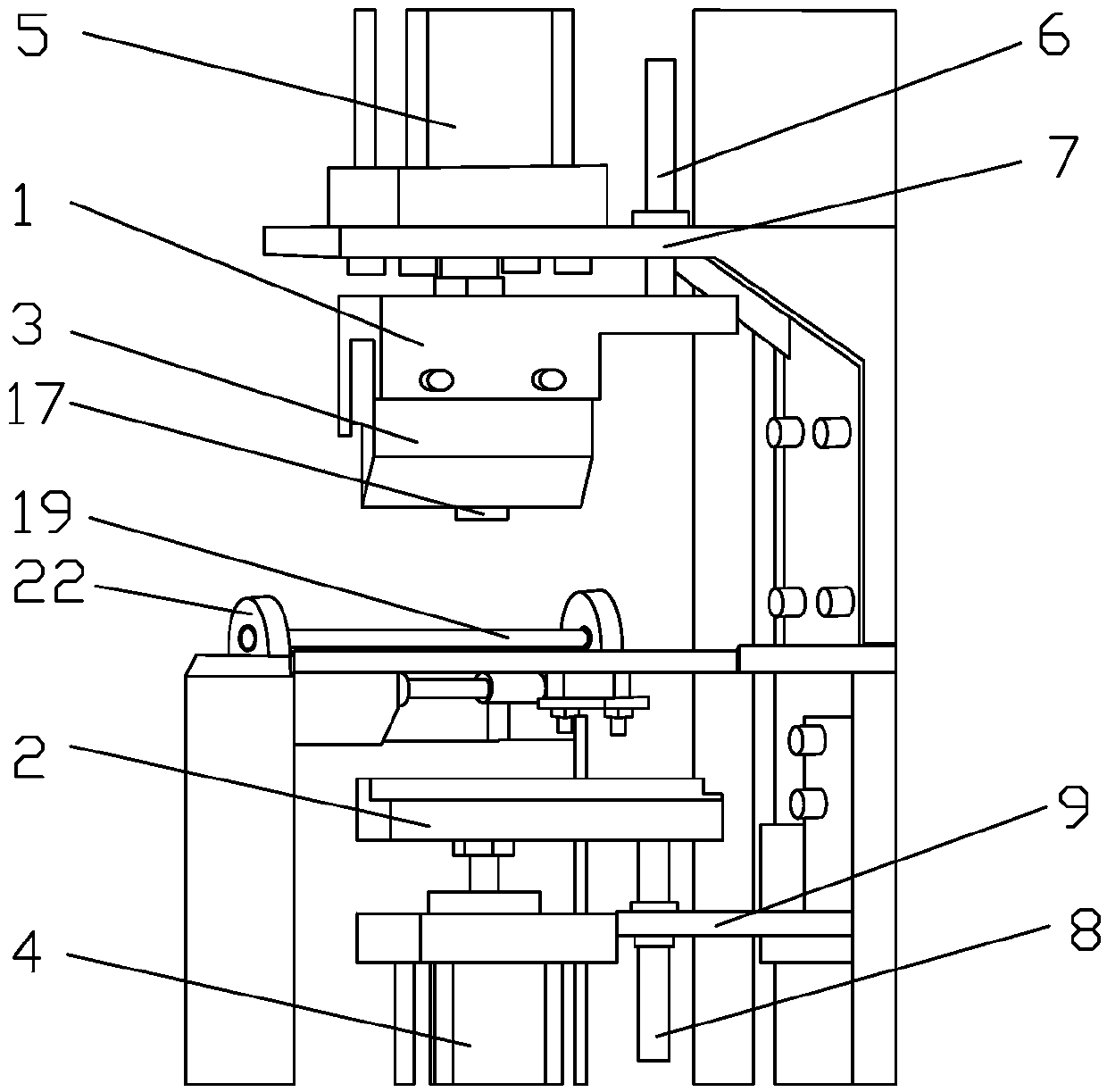

[0044] Such as Figure 1 to Figure 5 As shown, the present invention includes a frame 10, a flexible cable guiding mechanism installed on the frame 10, a flexible cable grabbing mechanism, a flexible cable pulling mechanism and a flexible cable cutting mechanism, and the flexible cable cutting mechanism includes A shearing unit, a driving unit for driving the shearing unit, a compression unit for compressing the flexible cable, and a guide unit for locating the moving direction of the shearing unit, the shearing unit includes knife holders arranged oppositely 1 and a shearing platform 2, a shearing knife 3 installed on the tool rest 1 is arranged between the knife rest 1 and the shearing platform 2, and the drive unit includes a shearing platform cylinder 4 for driving the shearing platform 2 to move and for The knife rest cylinder 5 that drives the knife rest 1 to move, the pressing unit includes a shearing and pressing module and a traction and pressing module, and the shear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com