Automatic loading and collecting mechanism for precision numerical-control machine tool

A technology of precise numerical control and collection mechanism, which is applied in the field of numerical control machine tools, can solve the problems of low material placement efficiency of workers, limited workpiece capacity, and high use value, and achieves the effect of facilitating inspection of workpiece quality, avoiding workpiece collision, and high use value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

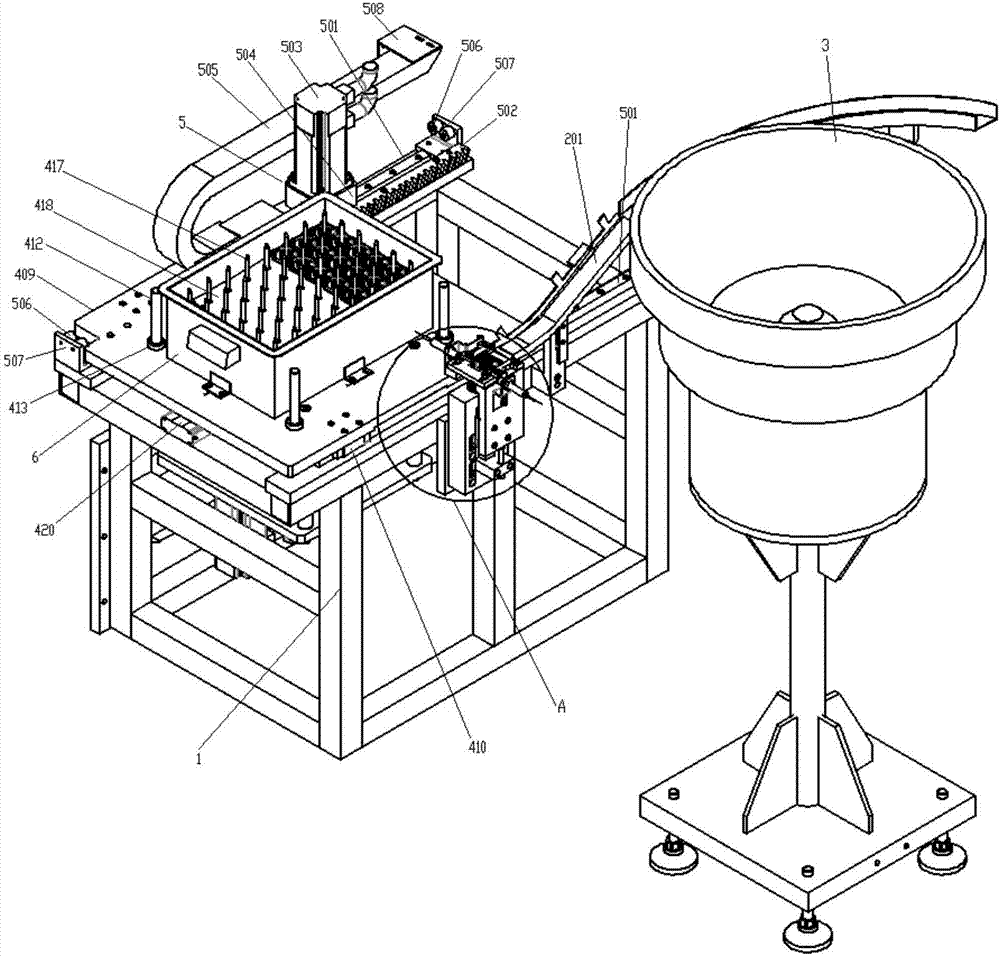

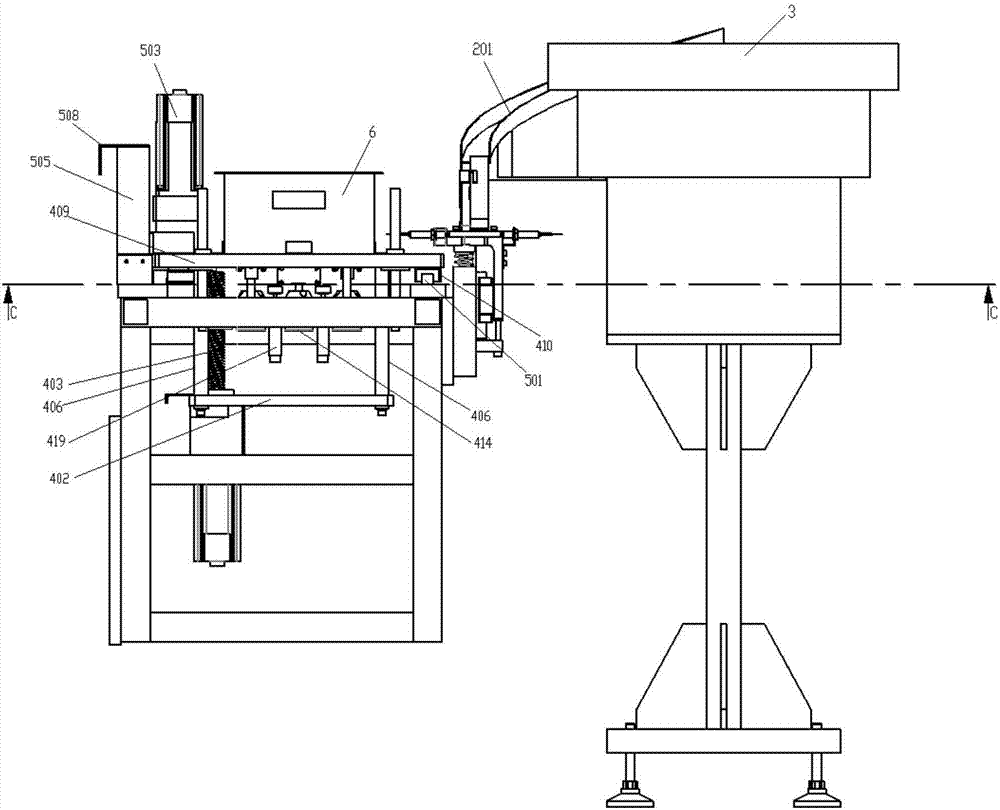

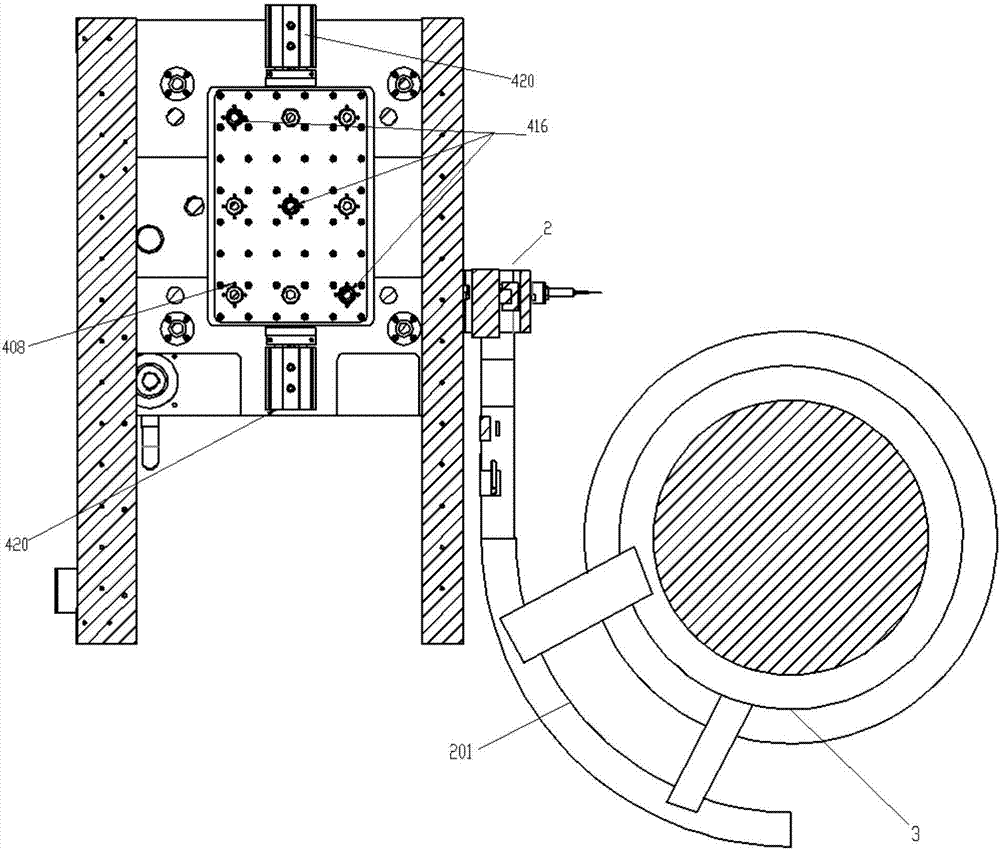

[0019] Attached below Figure 1-6 An embodiment of the present invention is described.

[0020]The automatic feeding and collecting mechanism used in precision numerical control machine tools has a base bracket 1, and the upper right end of the base bracket 1 is provided with a feeding device 2, and the upper end of the feeding device 2 is connected to a vibrating plate 3 located outside the right side of the base bracket 1 The upper end is fixedly connected, and the materials in the vibrating plate 3 are transported to the grabbing area through the feeding device 2 and positioned, and then the materials on the feeding device 2 are grabbed by the manipulator to the precision numerical control machine tool to realize the feeding of the materials. The middle part of the base support 1 is provided with a jacking mechanism 4 and the upper end surface of the jacking mechanism 4 is fixed with a turnover box 6. After the positioning mechanism 5 cooperates to realize the automatic co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com