Crawler transporter with automatic loading and unloading function

A transport vehicle, self-loading and unloading technology, which is applied in the direction of crawler vehicles, transportation and packaging, motor vehicles, etc., can solve the problems of inability to meet the transportation of four large-diameter steel pipes, slow walking speed, and low bearing capacity, and achieve long-distance The effect of remote control operation, improved transportation efficiency, and high equipment utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific examples.

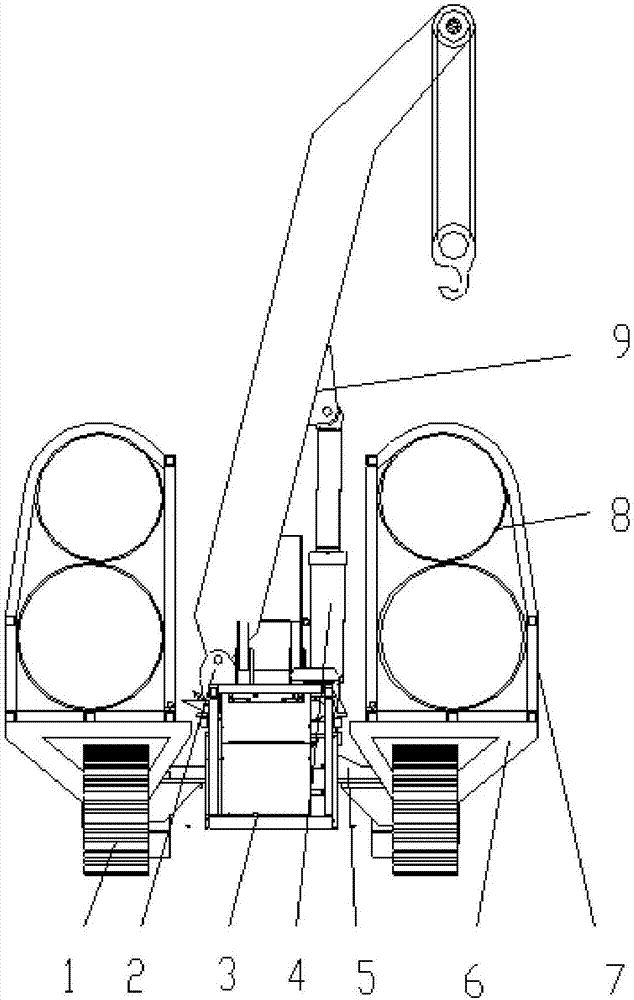

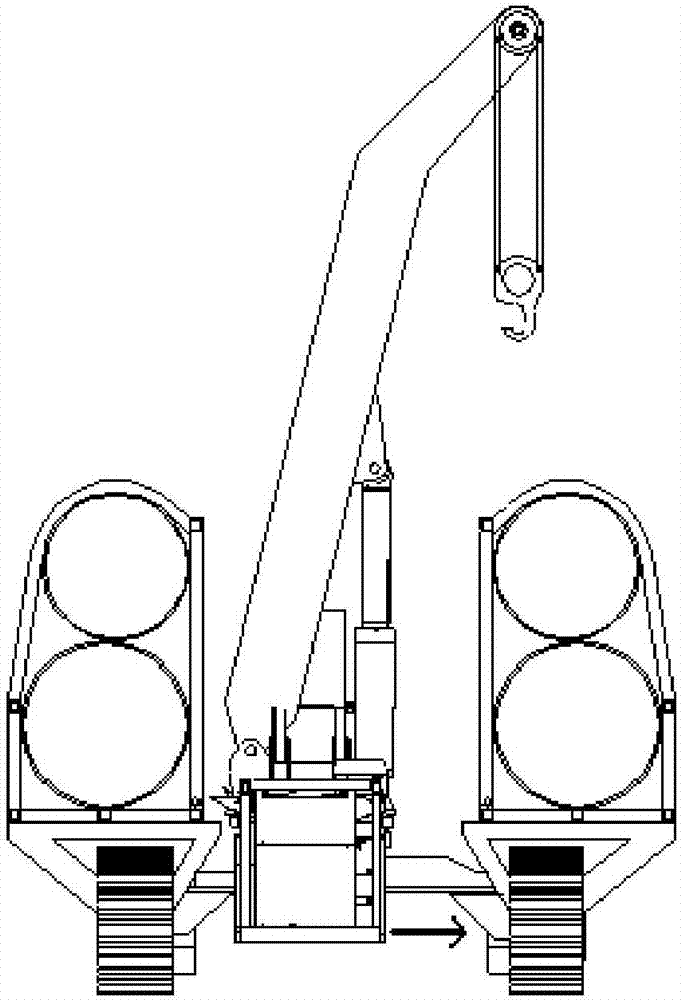

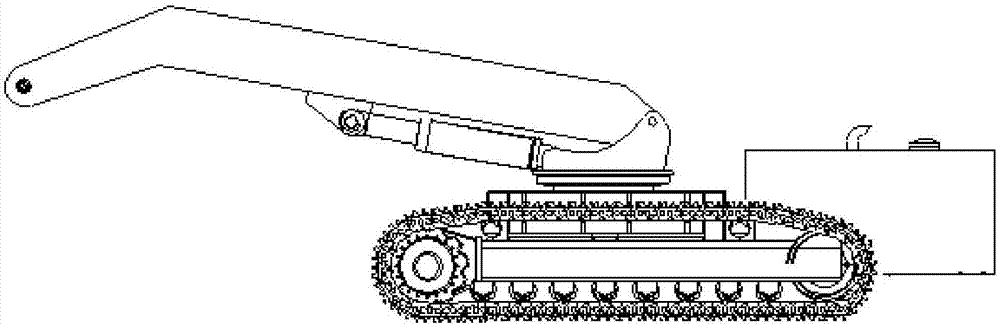

[0027] Such as Figure 1 to Figure 4 As shown, it is a kind of self-loading and unloading crawler transport vehicle of the present invention, including crawler beam 1, vehicle frame 5, slewing platform 2, boom 9, power box 3, pitching oil cylinder 4, crawler beam bracket 6, transport box 7 and Wireless remote control, track beam bracket 6 is connected on the track beam 1, two transport boxes 7 are respectively installed on the left and right track beam bracket 6, one end of the vehicle frame 5 is connected with the power box 3, and the other end of the vehicle frame 5 is connected with the power box 3. The crawler beam 1 is overlapped, the slewing platform 2 is set on the power box 3, and the slewing platform 2 is provided with a boom 9 and a pitching cylinder 4. The telescopic end of the pitching cylinder 4 is hinged with the middle part of the boom 9. The pitching of the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com