Metal sound barrier for bridge

A sound barrier and metal technology, applied in the direction of construction, noise absorption devices, etc., can solve the problems of increasing product weight, low strength of glass fiber cotton, increasing production process, etc., to achieve overall weight reduction, good sound absorption effect, high The effect of structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

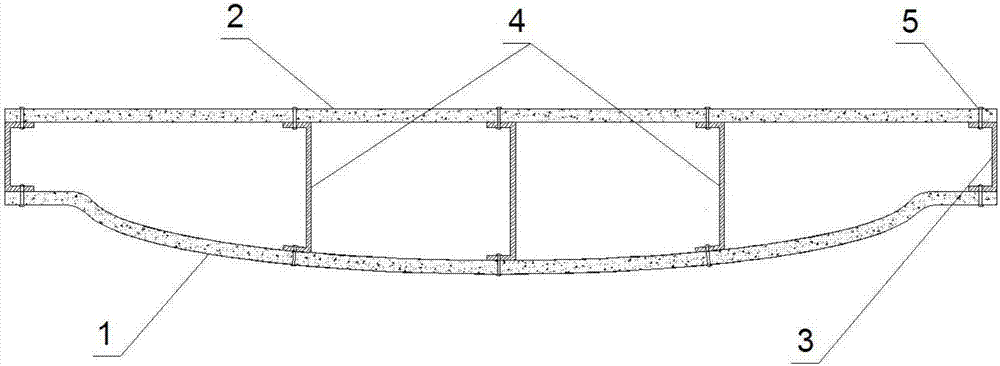

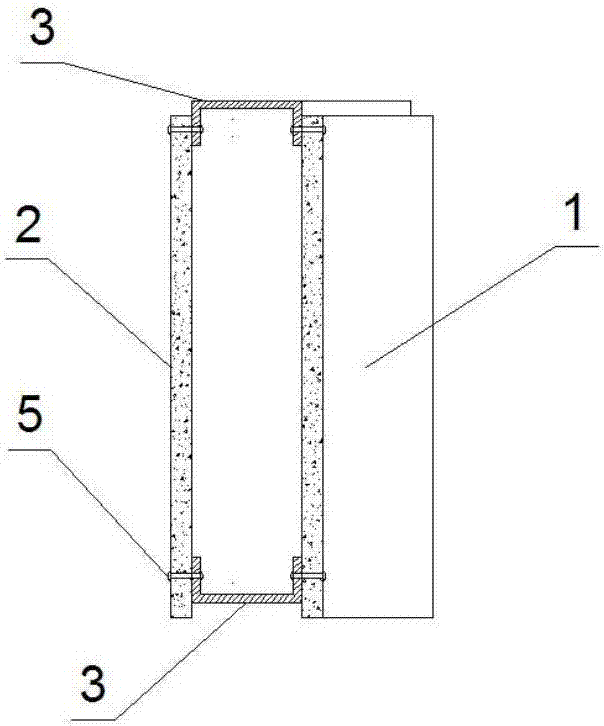

[0024] A metal sound barrier for a bridge, comprising a foamed aluminum panel 1, a backboard and galvanized steel sheets on four sides, the foamed aluminum panel 1 is micro-through-hole foamed aluminum, and the foamed aluminum backboard 2 is closed-cell foamed aluminum, The two ends of the foamed aluminum panel 1 are straight and the middle is an outwardly convex arc, the arc height is equal to the thickness of the sound barrier, the foamed aluminum backboard 2 is a flat plate, and the galvanized steel plate is pressed into a U-shaped section profiles, aluminum foam panels 1 and back panels and galvanized steel profiles 3 are fixedly connected with rivets 5 to form a metal sound barrier with a cavity structure, and the galvanized steel profiles 3 above the sound barrier slightly protrude from the panels and the back panel On the upper edge, the galvanized steel profile 3 below the sound barrier is slightly indented on the lower edge of the panel and the back panel, and three U-...

Embodiment 2

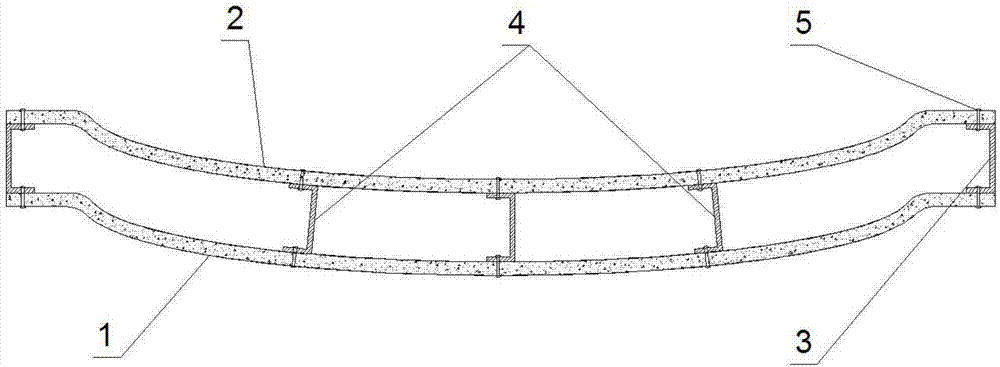

[0026] It is basically the same as Example 1, except that the foamed aluminum panel 1 is through-hole foamed aluminum, the foamed aluminum backboard 2 has the same shape as the panel and the arc protrudes in the same direction, and the cavity is filled with polyurethane foam material. The measured noise reduction coefficient of the product is 0.75, the weighted sound insulation is 35dB, the surface density is 25kg / m2, the bending fracture load is ≥7.0kPa, and the combustion performance is A1.

Embodiment 3

[0028] It is basically the same as Embodiment 2, except that the aluminum foam backboard 2 protrudes in the opposite direction to the arc of the panel, and the cavity is filled with glass fiber cotton. The measured noise reduction coefficient of the product is 0.77, the weighted sound insulation is 33dB, the surface density is 22kg / m2, the bending fracture load is ≥7.0kPa, and the combustion performance is A1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com