Steel latticed column combined-type tower crane infrastructure in foundation pit and construction method

A technology of steel lattice columns and composite towers, which is applied in basic structure engineering, construction and other directions, can solve the problems of high cost, difficult construction, and difficult construction, and achieve the effect of increasing structural stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical requirements for tower crane foundation construction will not be repeated in the present invention, and the structure involved in the present invention will be emphasized.

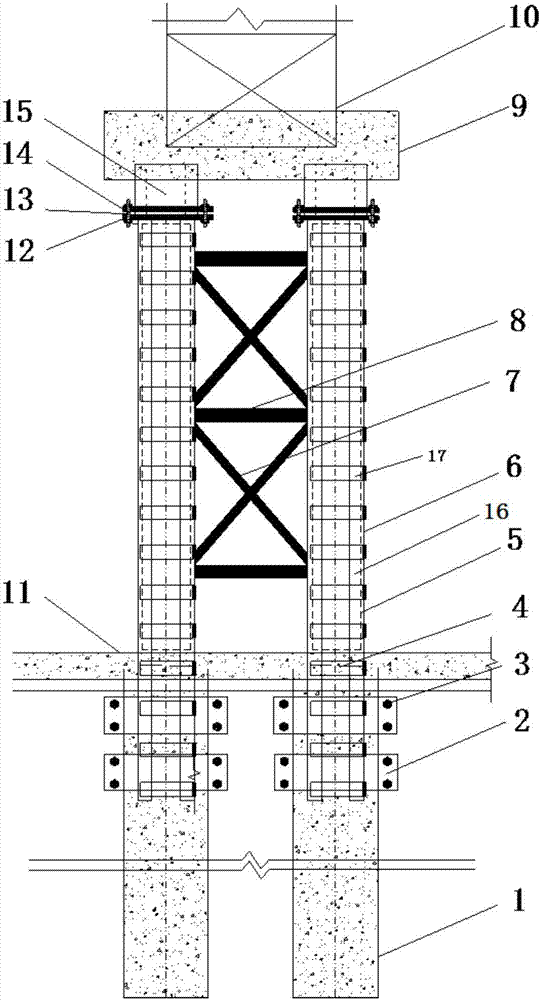

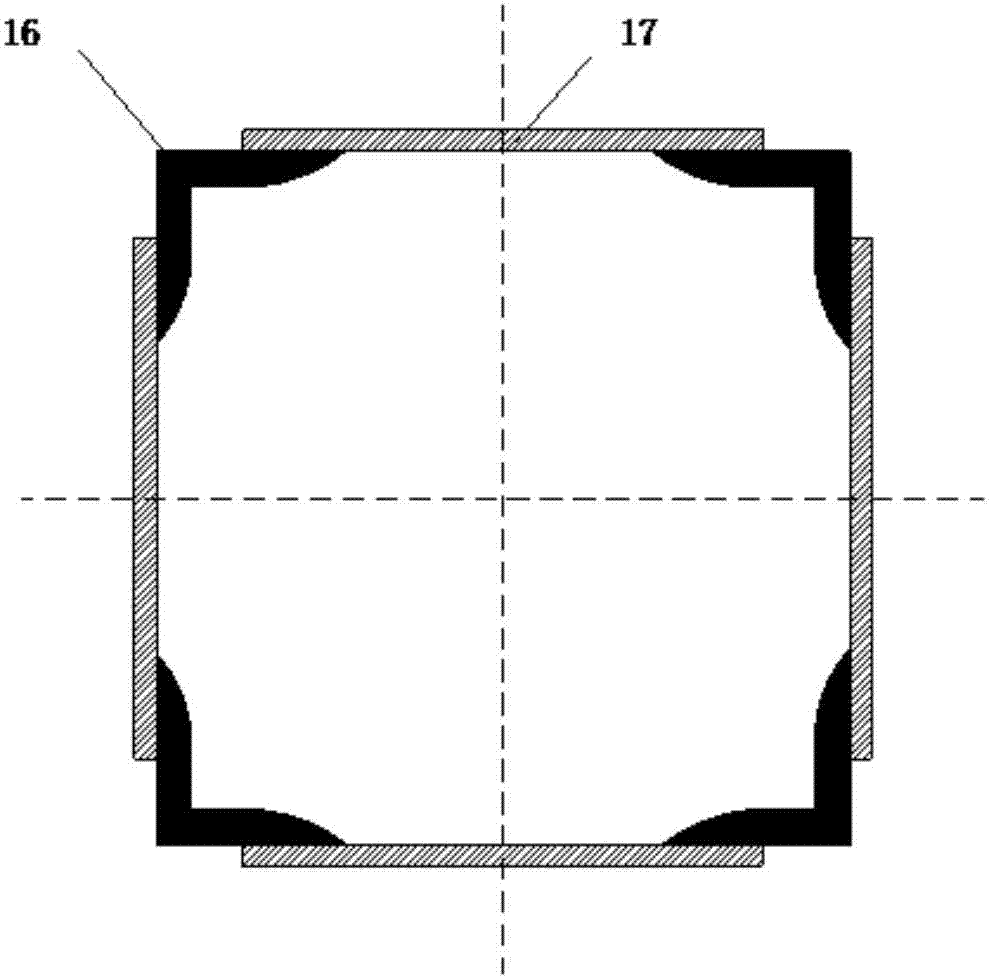

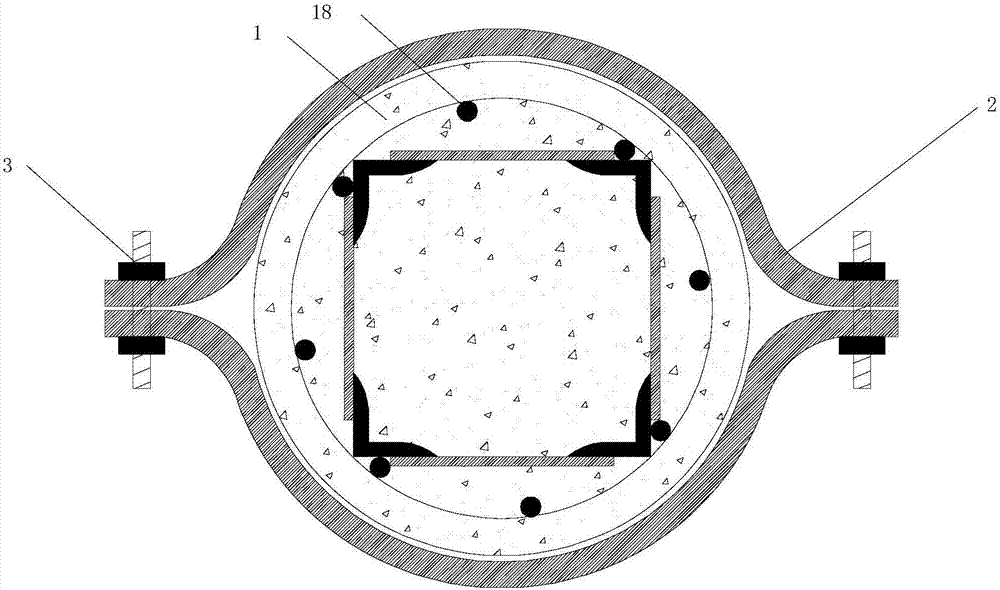

[0034] Such as Figure 1-5 As shown, the steel lattice column 6 composite tower crane foundation structure in the foundation pit described in this embodiment includes the prefabricated cast-in-situ piles 1 of the foundation pit and the foundation pit bottom 11, and the cast-in-place piles 1 are connected sequentially from bottom to top. Steel lattice column 6, steel column 15, cap 9 and tower crane pre-buried joint foundation 10, steel lattice column 6 is provided with concrete core column 5, and cast-in-place pile 1 is provided with a plurality of internal longitudinal reinforcements forming a reinforcement cage 18. The steel lattice column 6 is welded and fixed to the reinforcement cage inside the cast-in-place pile 1, and the welding section between the cast-in-situ pile 1 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com