Vertical valve core type PE (polyethylene) stop valve driven by miniature gear motor

A miniature geared motor, geared motor technology, applied in the valve operation/release device, valve details, valve device and other directions, can solve the problems of electric valve weight, high energy consumption, can not be opened, etc., to achieve low power and light weight , The effect of high technology content and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

[0025] In the present invention, for the convenience of description, the description of the relative positional relationship of each component is based on the figure 1 For example, the positional relationship of front, rear, top, bottom, left, right, etc. is determined according to the layout direction of the drawings in the description.

[0026] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

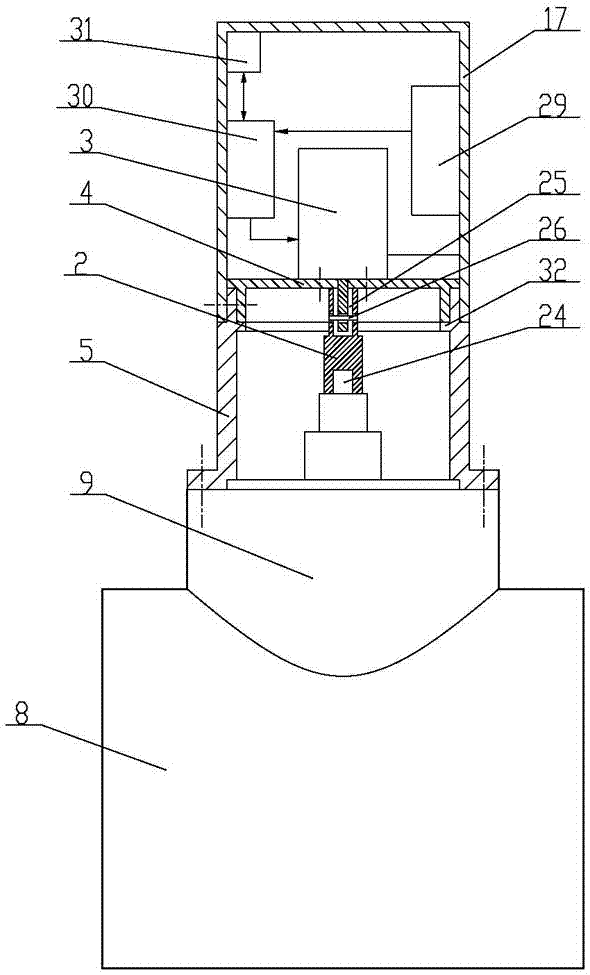

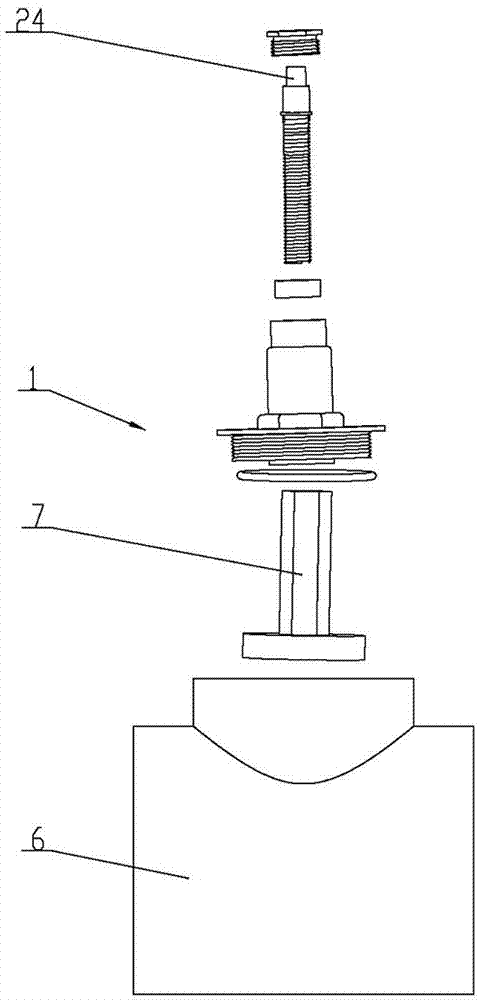

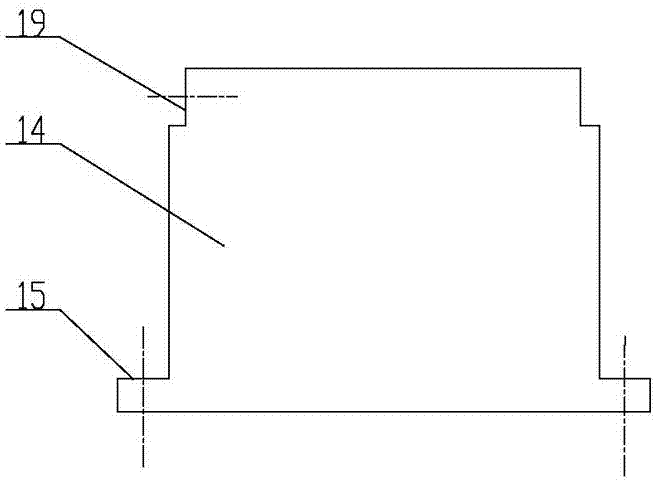

[0027] as attached figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, and 11, the vertical spool type PE cut-off valve driven by the miniature geared motor includes a PE cut-off valve body 1, a battery 29, a controller 30, a wireless Transceiver module 31, reduction motor 3, drive shaft 2, upper cover plate 4, lower sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com