Inward-inducing type flow equalization tube and application thereof

A flow equalizing tube and internal guide technology, applied in the direction of pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problem that the wind cannot blow to the left, the thickness of the glue layer is different, and the temperature error of the glue surface is large, etc. problem, to achieve the effect of consistent heat, simple processing and manufacturing, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

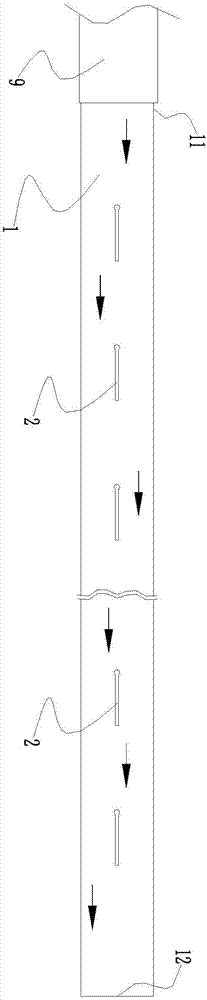

[0038] Such as Figure 1~2 As shown, a kind of internal guide type flow equalizing pipe, one end of the flow equalizing pipe 1 is a closed end 12, and the other end is an open end 11, and the open end 11 is connected with an air inlet pipe 9 to make the air flow to the flow equalizing pipe 1. At least one outlet air hole 2 is provided between the open end 11 and the closed end 12 of the flow equalizing pipe 1 so that the air is discharged to the outside of the flow equalizing pipe 1, and each outlet air hole 2 contains a plurality of air outlet holes 2 .

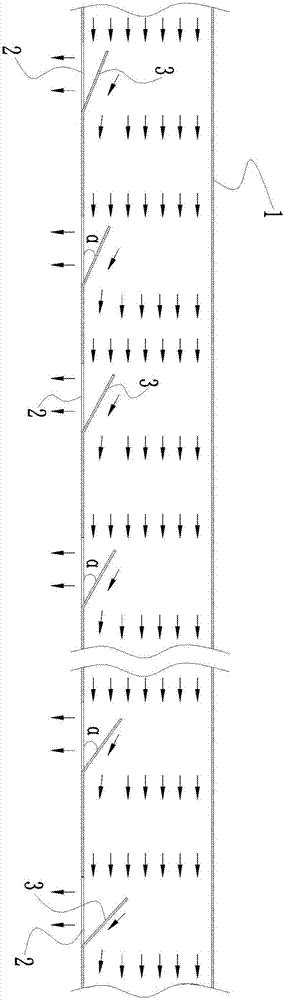

[0039] The flow equalizing pipe 1 is provided with a deflector 3 connected to the downstream end of the air flow inside the air outlet hole 2. Since the air outlet hole 2 has a certain length in the direction of the air flow, the downstream end of the air flow is the air outlet 2. In the present invention, the direction words such as left and right are only relative to the accompanying drawings; The angle α between the hol...

Embodiment 2

[0042] On the basis of Embodiment 1, in order to make the air output of each air outlet hole 2 consistent, further detailed limitations are made on the internal guide type flow sharing pipe 1, as follows.

[0043] Such as Figure 1~3 As shown, a plurality of the air outlet holes 2 in each row are evenly arranged on the flow equalizing pipe 1, and all the air outlet holes 2 have the same shape and size, that is, all the air outlet holes 2 are exactly the same hole.

[0044] Starting from the first air outlet hole 2 at the upper opening end 11 of the flow equalizing pipe 1, at every interval of 200-400 mm, the angle between the deflector 3 and the air outlet 2 increases by a gradient, and the increment of each gradient 1 to 5°. Specifically, in each air outlet hole 2, the distance N between the head and the tail of two adjacent air outlet holes 2 is 40-60 mm, preferably N is 50 mm, along the air flow direction, the air is discharged from the first Starting from the hole 2, the...

Embodiment 3

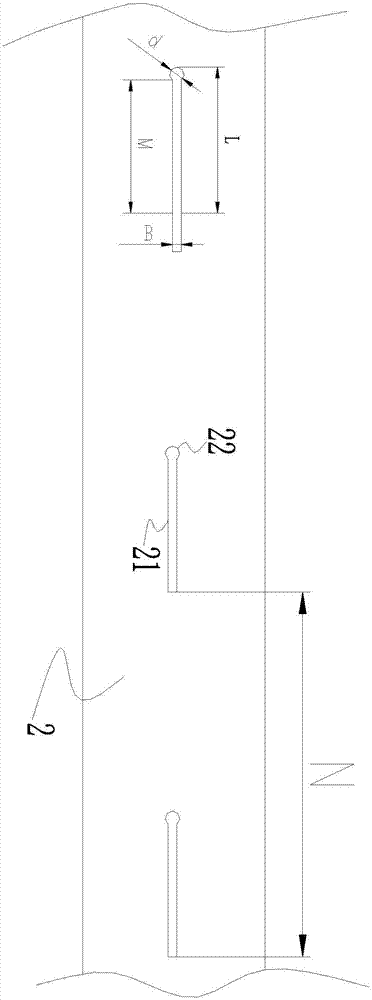

[0048] On the basis of Example 2, such as Figure 4~5 shown, where Figure 5 The middle dotted line part is the deflector 3 inside the tube, which is generally invisible from the outside.

[0049] The flow equalizing pipe 1 is a square pipe, and the upper end surface of the square pipe is provided with two discharge air holes 2, and the two discharge air holes 2 are arranged in a staggered arrangement. Among the two discharge air holes 2, two adjacent air discharge holes 2 The horizontal distance between the beginning and the end is 1 / 2 or half of the distance between the beginning and the end of two adjacent air outlets in each row. The meaning of this sentence is: any air outlet in any row 2 are all arranged between the two adjacent air outlet holes 2 in the other row before and after it, for example, if the distance N between the head and the tail of each row of adjacent two air outlet holes 2 in embodiment 2 is 50mm, Then in the two air outlet holes 2, the horizontal dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com