A vision-guided approach method for cascaded manipulators driven by an online CAD model

A model-driven, vision-guided technology, applied to mechanical equipment, character and pattern recognition, supporting machines, etc., can solve the problems of repetitive monotony, insufficient, and not too large differences, to avoid loss of image features in the field of view, simplify Work flow, avoid the effect of low precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with drawings and embodiments.

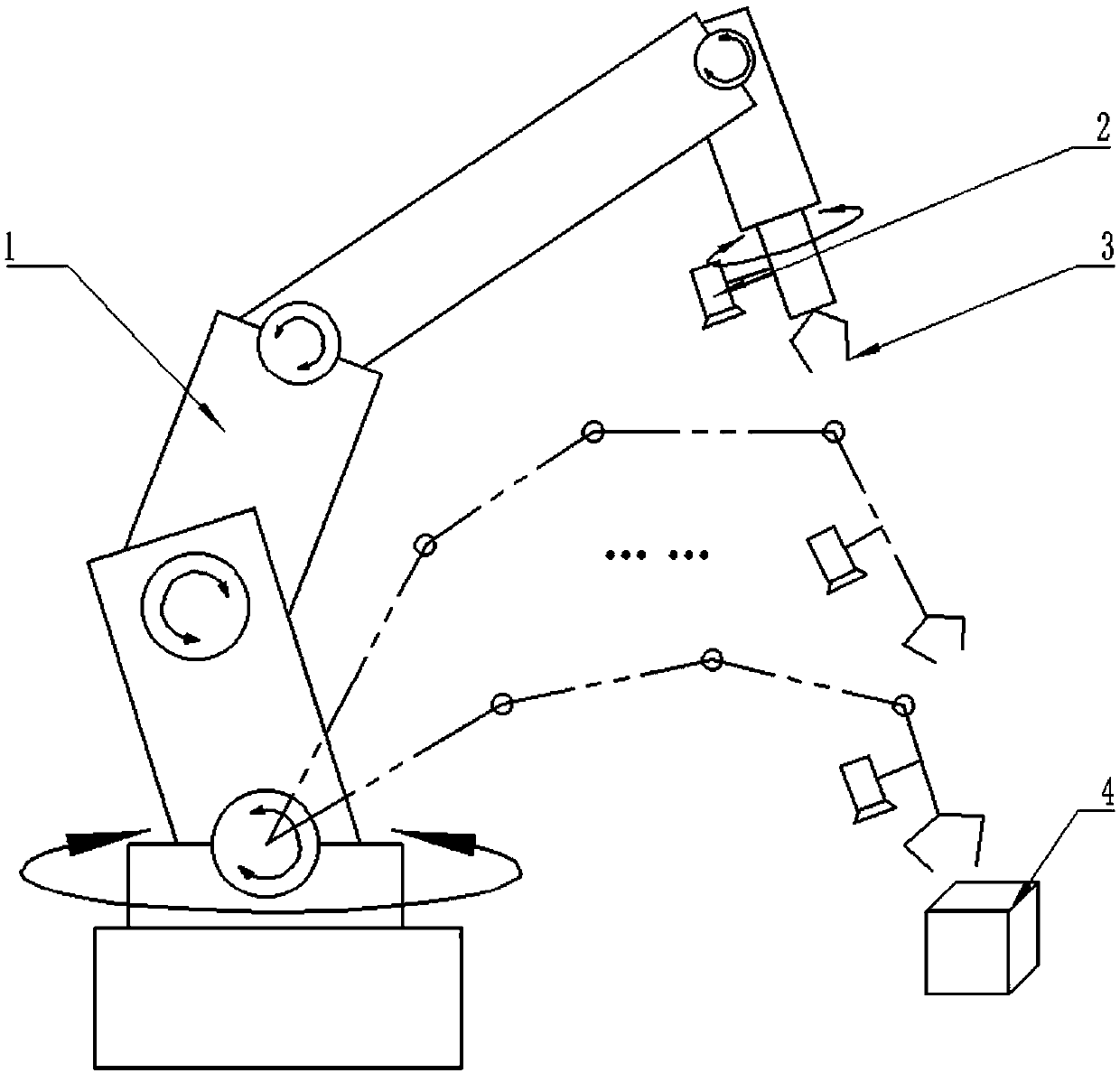

[0047] figure 1 A robotic assembly device capable of using embodiments of the present invention is shown. The system includes a six-axis robotic arm 1 , a monocular camera 2 and an end effector 3 , and 4 parts to be grasped. Wherein the monocular camera 2 is fixedly connected on the end effector 3 .

[0048] Before the method is implemented, the camera installed at the end of the manipulator is calibrated by the TSAI-LENZ method using a checkerboard calibration board.

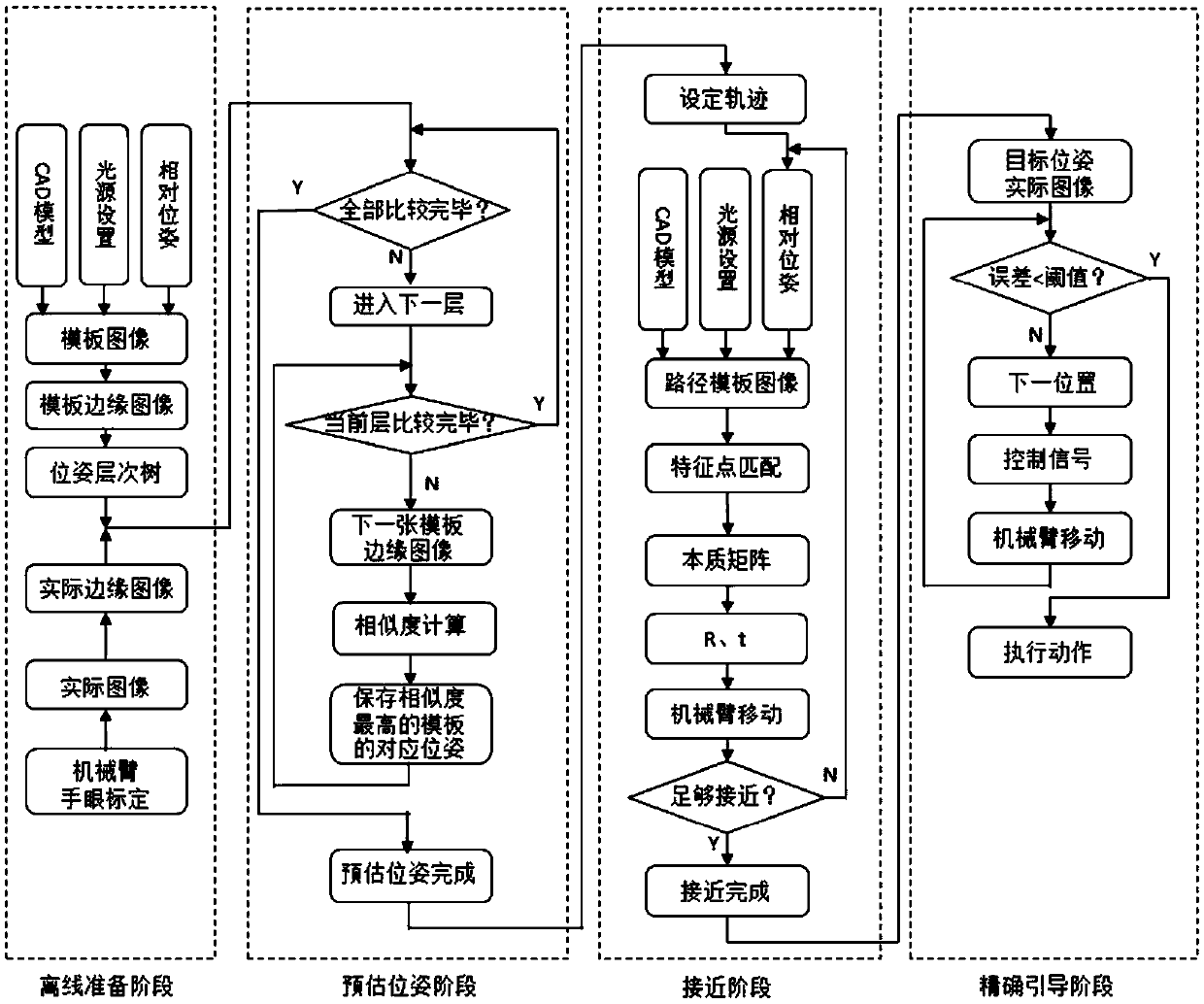

[0049] The first step is offline preparation. Create a 3D CAD model of the captured part. In order to obtain the two-dimensional image of the three-dimensional CAD model, the present invention preferably uses OpenGL to read the model, but is not limited to this graphics program interface, and other graphics program interfaces such as DirectX can be used. The line of sight is aligned with the origin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com