Wire bonding apparatus and bonding method of implantable micro-electronic product

A technology of wire bonding and microelectronics, which is applied in the field of biomedical engineering, can solve the problems of complicated wire bonding process and high cost, and achieve the effect of safe and stable bonding strength, low cost, and guaranteed safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

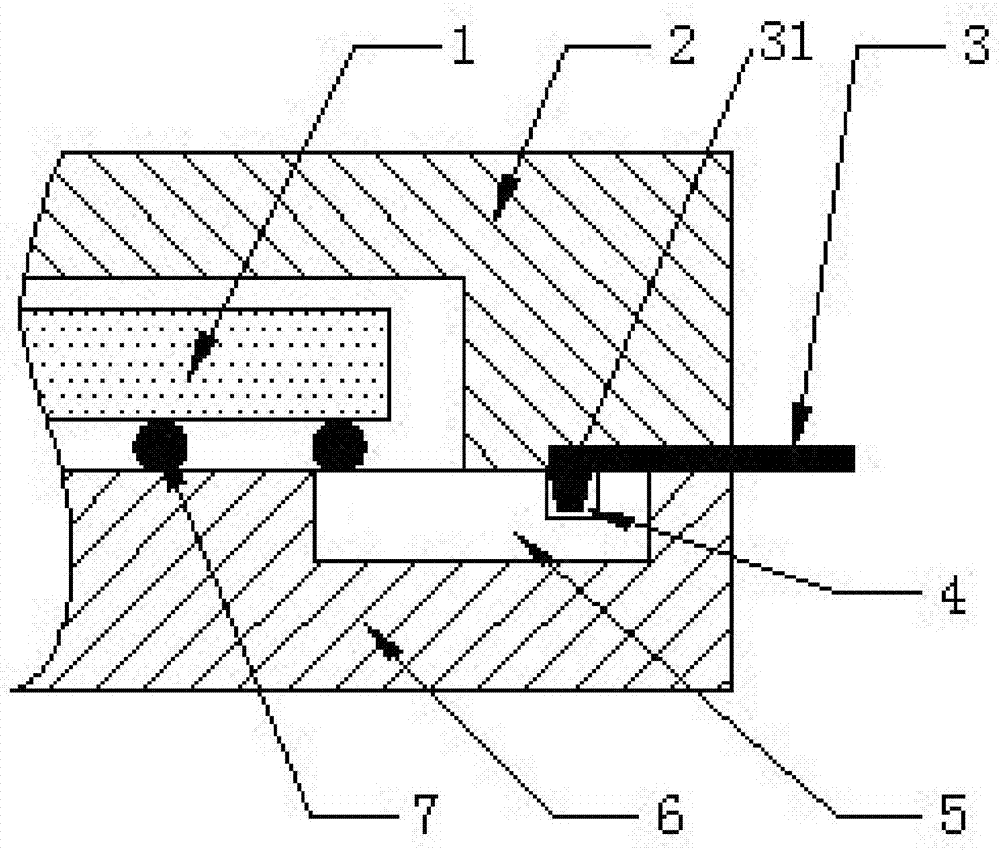

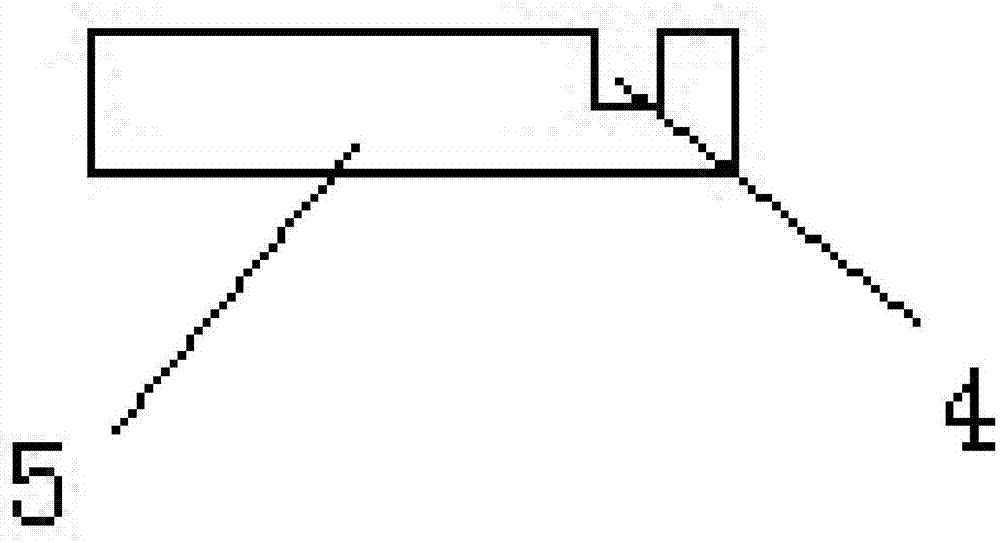

[0032] Such as figure 1 The shown wire bonding device for implantable microelectronic products of the present invention includes a plurality of wire connectors 5 embedded in the package base, and one end of the wire connectors 5 is connected to the package base and the housing 2 The chip 1 between them is electrically connected, the number of the wire connector 5 is set according to the connection point of the chip 1, and the position is set correspondingly according to the position of the connection point of the chip 1, and the other end is provided with a card slot 4, preferably Such as figure 1 and figure 2 As shown, the card slot 4 is formed by digging a groove on the wire connector 5, the card slot 4 is used to fix the end 31 of the cable 3, and the middle section of the cable 3 is pressed fit between the package base and the case 2.

[0033] In a preferred embodiment, the slot 4 of the wire connector 5 and the end 31 of the cable 3 are fused and welded with a small a...

Embodiment 2

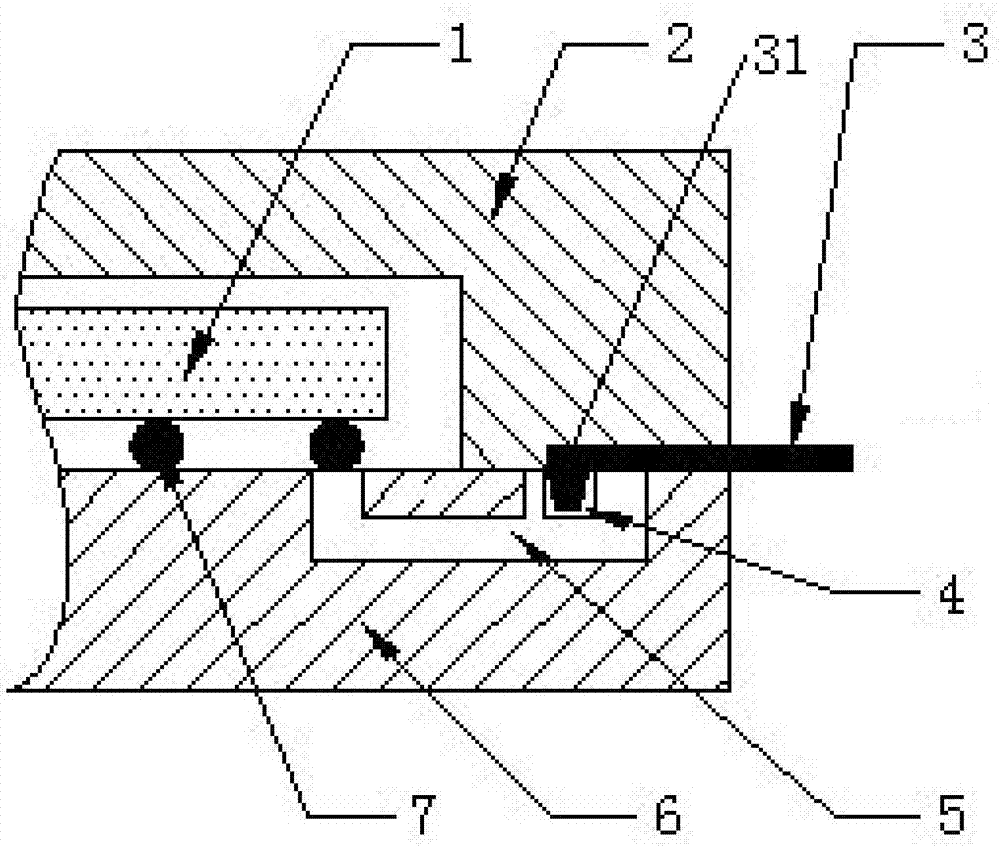

[0040] In this example, if image 3 The shown wire bonding device for implantable microelectronic products of the present invention includes a plurality of wire connectors 5 embedded in the package base, and one end of the wire connectors 5 is connected to the package base and the housing 2 The chip 1 is connected between them, the number of the wire connectors 5 is set according to the connection point of the chip 1, and the position is set correspondingly according to the position of the connection point of the chip 1, and the other end is provided with a card slot 4, preferably as image 3 and Figure 4 shown. A welding slot 51 is also formed inside the clamping slot 4 , wherein the clamping slot 4 is used to fix the end 31 of the cable 3 . The fixing groove 51 is filled with the same material as that of the packaging shell 2, this embodiment can solve the defect of incompatibility of the packaging interface, and provides a guarantee of airtight packaging.

Embodiment 3

[0042] In this embodiment, a wire bonding device method for implantable microelectronic products is provided, including the following steps:

[0043] S1: Pre-embed a plurality of wire connectors 5 in the package base. In practice, the base material of the package base and the wire connectors are formed by melting or sintering. The mechanical properties are good, and the chip 1 is passed through Flip-chip welding is electrically connected to one end of the wire connector 5;

[0044] S2: After physically inserting the end 31 of the cable 3 into the card slot 4, a small amount of solder fusion welding is performed on the contact between the two; and the method of micro solder fusion welding is a well-known technical means in the welding field, and is adopted in the present invention. A small amount of solder fusion welding has a low melting point and small diffusion, and it needs to maintain a long-term effective connection.

[0045] S3: Finally, the casing 2 is hermetically bon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com