Alkaline zinc-manganese battery with low internal resistance and preparation method of alkaline zinc-manganese battery

A zinc-manganese battery, low internal resistance technology, applied in the field of electrochemistry, can solve problems such as excessive internal resistance, and achieve the effects of reducing internal resistance, simple preparation method and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

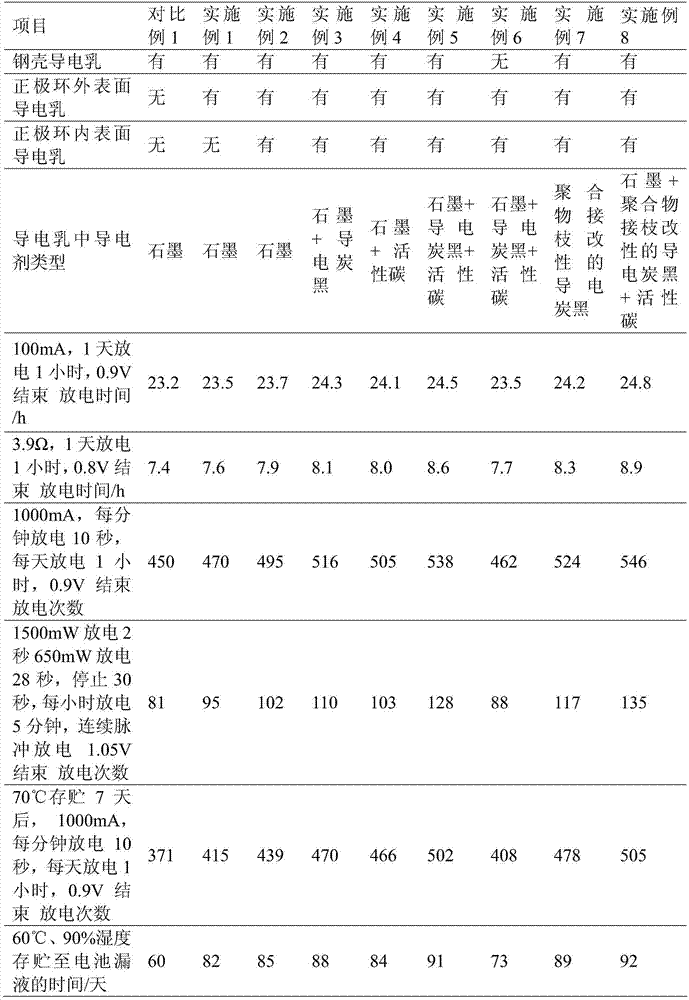

Examples

Embodiment 1

[0025] Using a spray device, under the conditions of pressure 1MPa and spraying frequency 1s / time, spray the conductive emulsion with graphite as the conductive agent on the outer surface of the positive electrode ring of alkaline zinc-manganese dry battery, with a thickness of 8μm, and put it into the battery coated with conductive emulsion after drying In the steel shell, a diaphragm paper tube is inserted in the middle, and the electrolyte is injected into the diaphragm paper tube. After the electrolyte is completely absorbed by the diaphragm paper tube and the positive electrode ring, zinc paste is injected, and a copper nail with a negative electrode cover is inserted, and the product is obtained by pressing and sealing.

Embodiment 2

[0027] Using a spraying device under the condition of a pressure of 4MPa and a spraying frequency of 0.5s / time, the conductive emulsion with graphite as the conductive agent is sprayed on the outer surface and inner surface of the positive electrode ring of the alkaline zinc-manganese dry battery, with a thickness of 2 μm. The remaining preparation methods and examples 1 is exactly the same.

Embodiment 3

[0029] Use a spray device under the condition of a pressure of 8MPa and a spraying frequency of 0.1s / time, to spray the conductive emulsion with graphite and conductive carbon black on the outer surface and inner surface of the positive electrode ring of the alkaline zinc-manganese dry battery, with a thickness of 90 μm, and prepare the rest Method is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com