Organic hydrophilic coating composition, hydrophilic film and aluminum material for heat exchanger

A technology of hydrophilic coatings and compositions, applied in the direction of polyether coatings, lighting and heating equipment, coatings, etc., to achieve the effect of easy cleaning operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

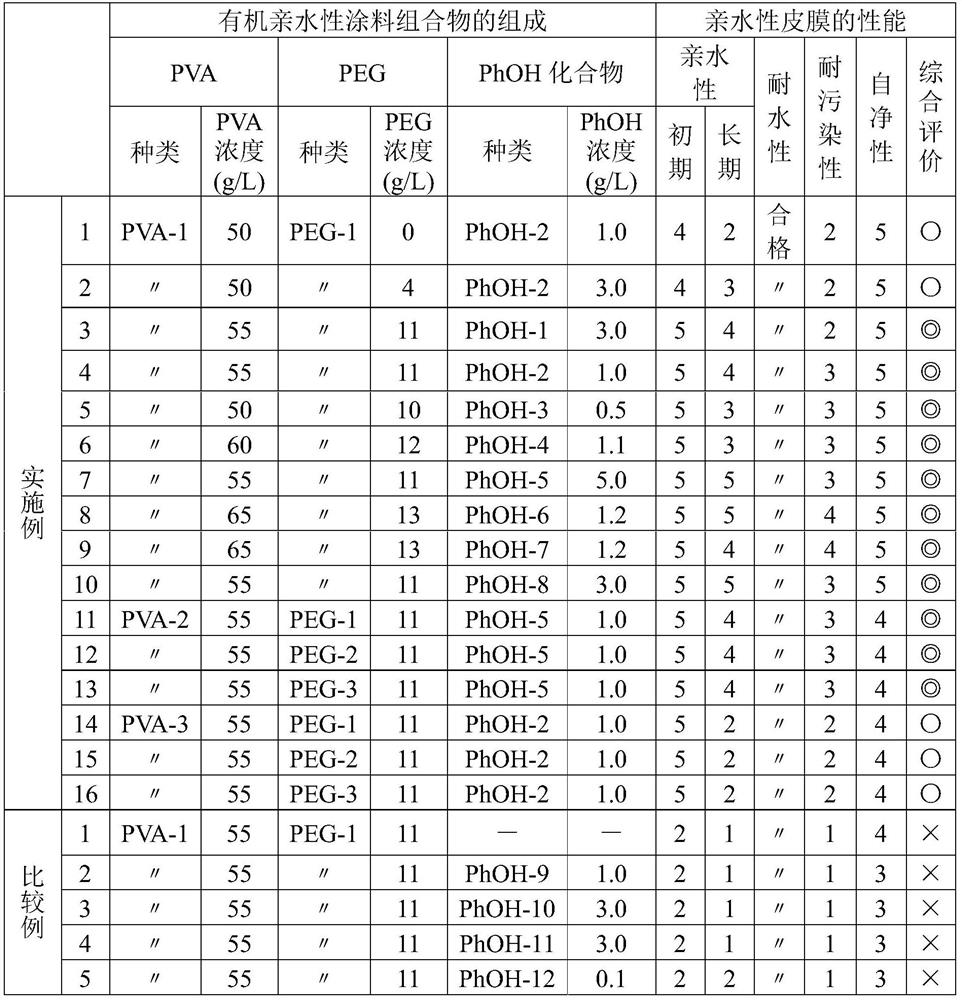

Embodiment 1~14 and comparative example 1~5

[0076] The polyvinyl alcohol resin (PVA) used as the resin component [PVA-1]: polyvinyl alcohol with a degree of saponification of 99.3% and an average degree of polymerization of 1000 (Nippon Vinyl Acetate and Polyvinyl Alcohol Co., Ltd. Manufactured trade name: VC-10), [PVA-2]: polyvinyl alcohol having a saponification degree of 98.0% and an average polymerization degree of 1700 (trade name manufactured by Japan Vinyl Acetate and Polyvinyl Alcohol Co., Ltd.: JF-17L) , and [PVA-3]: polyvinyl alcohol with a degree of saponification of 97.0% and an average degree of polymerization of 1700 (trade name: VM-17 manufactured by Japan Vinyl Acetate and Polyvinyl Alcohol Co., Ltd.); Ethylene glycol resin (PEG) used [PEG-1]: polyethylene glycol (trade name manufactured by Sanyo Chemical Industry Co., Ltd. (Sanyo Chemical Industry Co., Ltd.: PEG-6000S) with a number average molecular weight of 6000), [ PEG-2]: polyethylene glycol with a number average molecular weight of 1500 (trade nam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com