Real stone paint for building exterior wall and preparation method thereof

A technology for building exterior walls and real stone paint, which is applied to biocide-containing paints, coatings, antifouling/underwater coatings, etc., which can solve the problem of damage to the bond strength of real stone paint, sand loss on the surface of real stone paint, and non-dense paint film and other problems, to achieve the effect of improving stain resistance, improving smoothness, and ensuring stain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

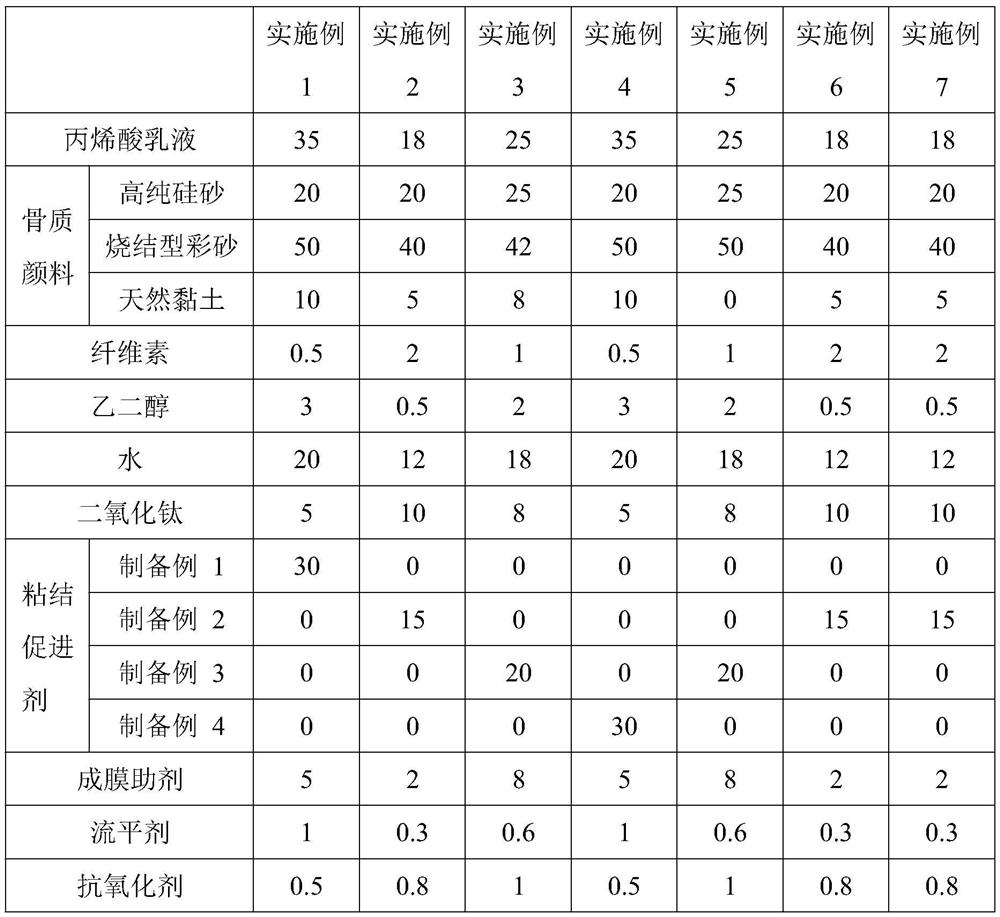

Examples

preparation example 1

[0069] Adhesion promoters are made by the following steps:

[0070] Step 1: Soak and dissolve 10 parts of ceramic particles in 2 parts of isopropanol and 0.8 part of polyvinylpyrrolidone, ball mill and disperse for 2 hours at a speed of 1500 r / min, and then stand and filter to obtain pretreated ceramic particles.

[0071] Step 2: Add 8 parts of silane coupling agent to 15 parts of polyurethane, slowly add 0.5 parts of acetic acid solution dropwise while stirring, divide the pretreated ceramic particles prepared in step 1 into 4 parts on average, and divide each part of pretreated ceramic particles in turn Add it at an interval of half an hour, and continue to stir at a stirring rate of 500r / min for 3 hours to obtain the adhesion promoter.

preparation example 2

[0073] Adhesion promoters are made by the following steps:

[0074] Step 1: Soak and dissolve 5 parts of ceramic particles in 1.5 parts of isopropanol and 0.1 part of polyvinylpyrrolidone, ball mill and disperse for 1 hour at a speed of 2000 r / min, then stand and filter to obtain pretreated ceramic particles.

[0075] Step 2: Add 3 parts of silane coupling agent to 8 parts of polyurethane, slowly add 0.5 parts of acetic acid solution dropwise while stirring, divide the pretreated ceramic particles prepared in step 1 into 3 parts on average, and divide each part of pretreated ceramic particles in turn Add it at an interval of half an hour, and continue to stir at a stirring rate of 800r / min for 5 hours to obtain the adhesion promoter.

preparation example 3

[0077] Adhesion promoters are made by the following steps:

[0078] Step 1: Soak and dissolve 8 parts of ceramic particles in 1 part of isopropanol and 0.5 part of polyvinylpyrrolidone. At a speed of 3000 r / min, disperse by ball milling for 1.5 hours, and then stand and filter to obtain pretreated ceramic particles.

[0079] Step 2: Add 5 parts of silane coupling agent to 25 parts of polyurethane, slowly add 0.5 parts of acetic acid solution dropwise while stirring, divide the pretreated ceramic particles prepared in step 1 into 6 parts on average, and divide each part of pretreated ceramic particles in turn Add it at an interval of half an hour, and continue to stir at a stirring rate of 700r / min for 6 hours to obtain the adhesion promoter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| loss on ignition | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com