A kind of silicone modified polyether polyol and its preparation method and application

A polyether polyol, silicone technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of practical limitations, can not achieve super-hydrophobicity, etc., achieve good stability, good extension, strong adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In the present embodiment, the preparation of silicone-modified self-cleaning polyurethane water-based coating comprises the following steps:

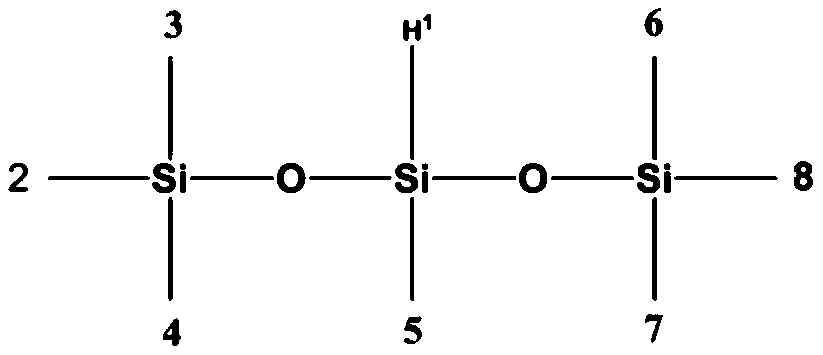

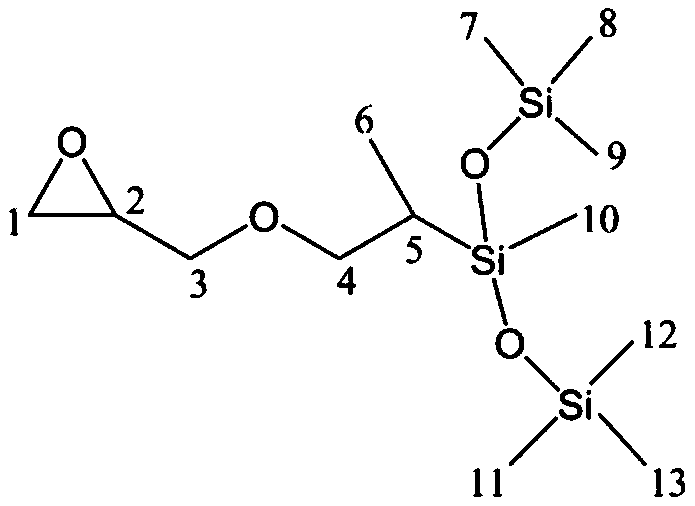

[0022] Step 1. Addition reaction of allyl glycidyl ether and heptamethyltrisiloxane (molar ratio: 1:1), using chloroplatinic acid as a catalyst, and reacting for 6 hours at a reaction temperature of 80°C under nitrogen protection , to obtain modified allyl glycidyl ether. Chloroplatinic acid is added in the form of a solution, the solvent is toluene, the concentration of chloroplatinic acid in the solution is 20ppm, and the amount of chloroplatinic acid solution added is 50% of the total mass of the material, while the reaction is condensed and refluxed, after the reaction is finished, the distillation Remove solvent.

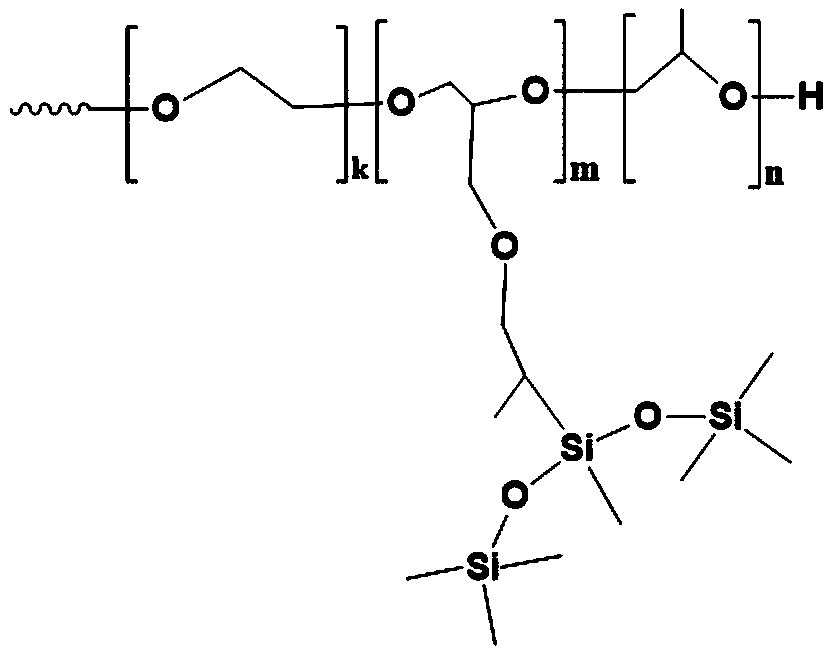

[0023] Step 2, adding propylene oxide and diethylene glycol to the modified allyl glycidyl ether obtained in step 1, the molar ratio of allyl glycidyl ether to diethylene glycol is 2:1, in the reaction kettle C...

Embodiment 2

[0031] In the present embodiment, the preparation of silicone-modified self-cleaning polyurethane water-based coating comprises the following steps:

[0032] Step 1, polymerize 1mol allyl glycidyl ether, 11mol propylene oxide and 1mol ethylene glycol, the reaction conditions are potassium hydroxide catalysis (addition amount is 0.1% of the total mass of the material), nitrogen protection, 100 ° C reaction 6h to obtain polyether diol.

[0033] In step 2, add 1 mol of heptamethyltrisiloxane to the polyether diol obtained in step 1. The reaction conditions are catalyzed by chloroplatinic acid, protected by nitrogen, and reacted at 90°C for 5 hours. The chloroplatinic acid is in the form of a solution Add, solvent is xylene, and the concentration of chloroplatinic acid in solution is 50ppm, and the addition of chloroplatinic acid solution is 30% of material gross mass, carries out condensing reflux while reacting, after reaction finishes, distillation removes solvent, obtains mole...

Embodiment 3

[0038] In the present embodiment, the preparation of silicone-modified self-cleaning polyurethane water-based coating comprises the following steps:

[0039]Step 1. Addition reaction of allyl glycidyl ether and heptamethyltrisiloxane (molar ratio: 0.8:1), using chloroplatinic acid as catalyst, reacting for 7 hours at a reaction temperature of 60°C under nitrogen protection , to obtain modified allyl glycidyl ether. Chloroplatinic acid is added in the form of a solution, the solvent is isopropanol, the concentration of chloroplatinic acid in the solution is 3ppm, and the amount of chloroplatinic acid solution added is 90% of the total mass of the material, while the reaction is condensed and refluxed, the reaction ends The solvent was then distilled off.

[0040] Step 2, add propylene oxide and propylene glycol to the modified allyl glycidyl ether obtained in step 1, the molar ratio of allyl glycidyl ether to propylene glycol is 1:1, carry out polymerization reaction in the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com