Tail gas purifier and honeycomb carrier coating process

A tail gas purifier and coating process technology, applied in chemical instruments and methods, exhaust devices, molecular sieve catalysts, etc., can solve problems such as poor filtering effect, environmental pollution, incomplete tail gas purification, etc., and achieve uniform slurry coating , good filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

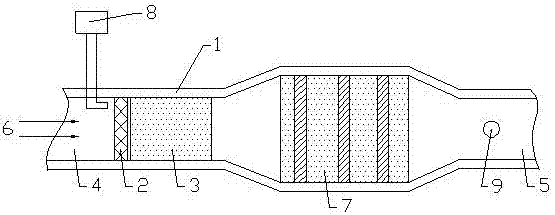

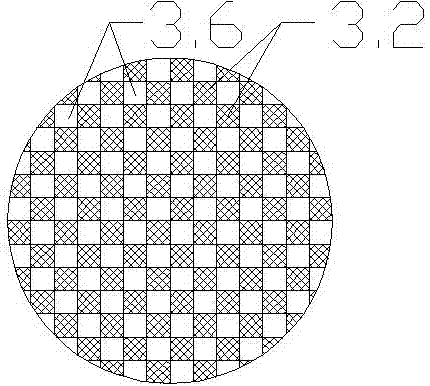

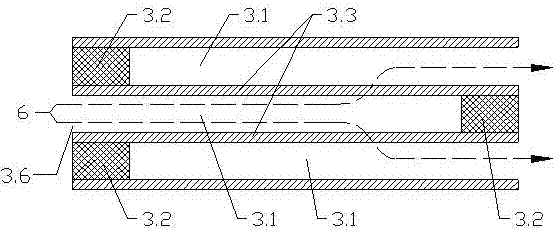

[0036] see Figure 1-4 , the present invention relates to a kind of tail gas purifier, it comprises filter box 1, filter screen 2, ceramic honeycomb carrier 3 and low-temperature catalytic area 7, the two ends of filter box 1 are thin sections, the middle part is thick section, the left end of filter box 1 is The exhaust gas inlet 4, the right end is the exhaust gas outlet 5, the filter screen 2, the ceramic honeycomb carrier 3 and the low-temperature catalytic zone 7 are arranged in the filter box 1, the filter screen 2 and the ceramic honeycomb carrier 3 are near the exhaust gas inlet 4, and the low-temperature catalytic zone 7 Set in the thick section of the filter box 1, the low-temperature catalytic zone 7 is filled with low-temperature catalyst, the filter box 1 is in the shape of a circular tube, the ceramic honeycomb carrier 3 corresponds to the inner wall of the filter box 1, and the ceramic honeycomb carrier 3 is along the axis There are air holes 3.1 densely distrib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com