Smoke storage type filtering apparatus

A filter device and smoke storage technology, applied in the fields of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of smoke, exhaust gas emission, etc., and achieve the effect of simple structure, convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

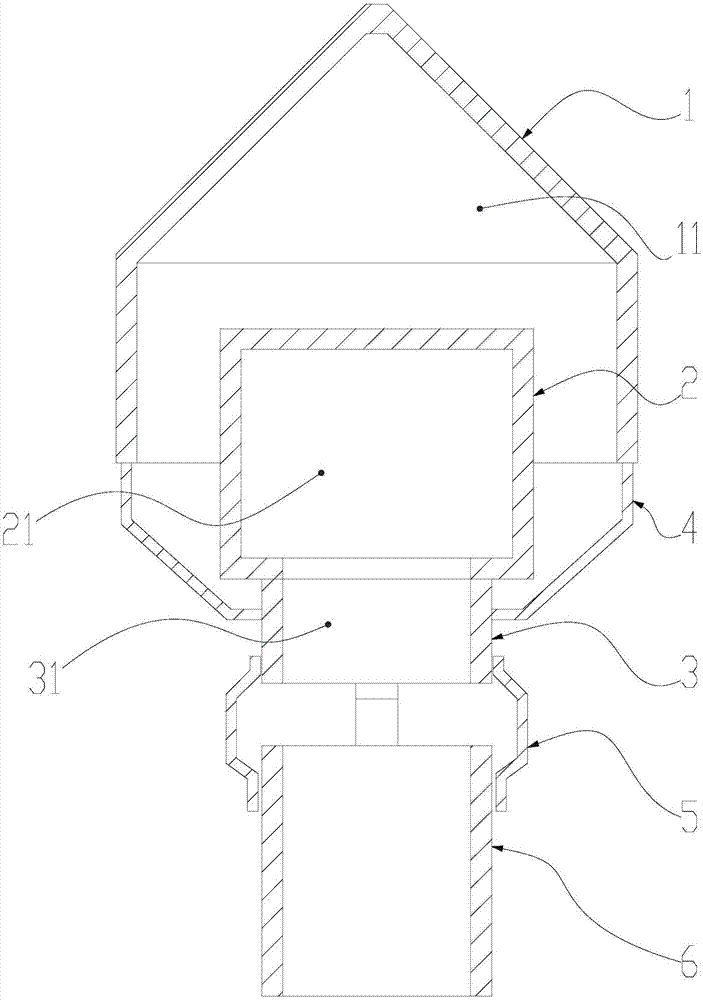

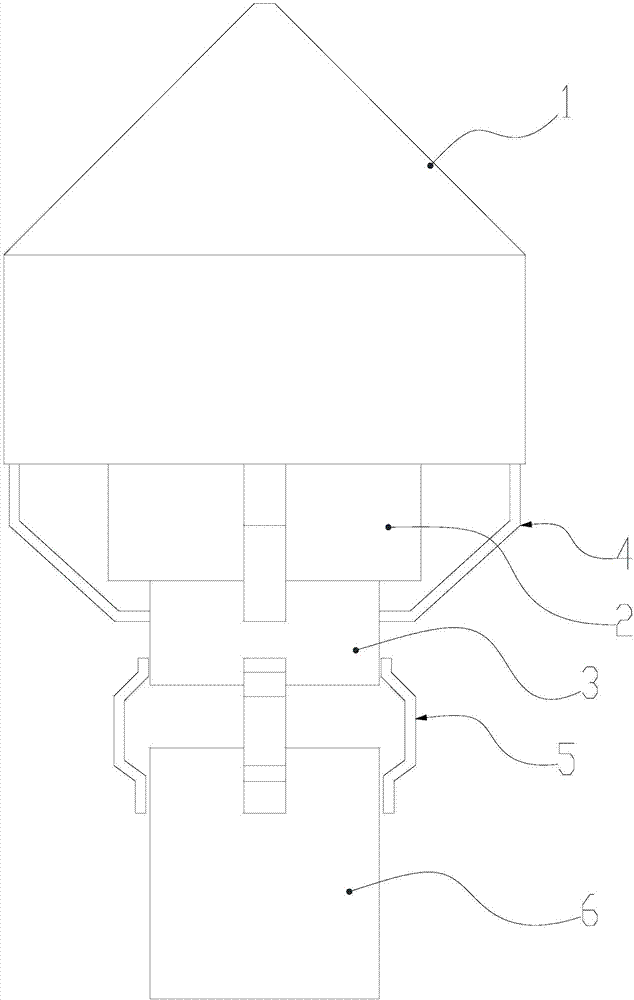

[0027] Such as Figures 1 to 2 The shown smoke storage filter device includes a protective cover 1 , a filter cover 2 , a load-bearing member 3 , a fixed rod 4 and a movable connecting rod 5 . Above-mentioned filter cover 2 is installed on the top of load-bearing fixture 3. The above-mentioned protective cover 1 and the load-bearing member 3 pass through the fixed rod 4, so that the protective cover 1 is fixedly connected directly above the filter cover 2, and there is a certain gap between the filter cover 2 and the filter cover 2. One end of the movable connecting rod 5 is fixed on the load-bearing member 3 , and the other end is fixed on the smoke exhaust channel 6 .

[0028] In order to ensure that the filter cover 2 can effectively avoid the sun, rain, wind and rain to the greatest extent, improve the service life of the filter cover 2, reduce unnecessary external interference, and at the same time ensure that the filtering effect is not greatly affected, A housing cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com