Process and Dynamic Control Scheme of Separation of Benzene and Isobutanol by Pressure Swing Distillation

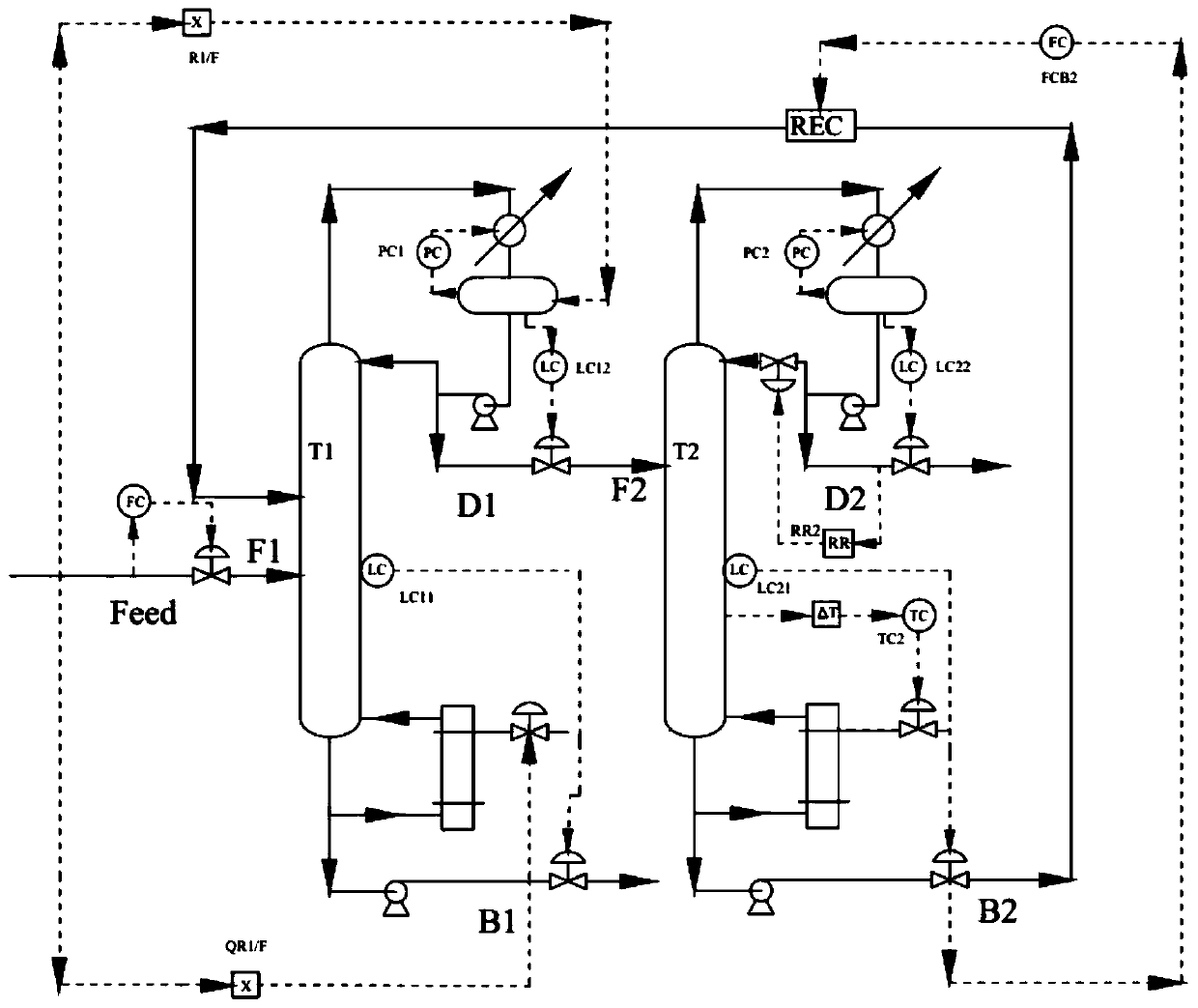

A pressure swing rectification and isobutanol technology, which is applied in the dynamic control of the pressure swing rectification process, the pressure swing rectification separation process of benzene and isobutanol mixture and the field of dynamic control scheme, which can solve the problem that the rectification tower is not given. The types of separated substances, the difficulty of dynamic control of double-tower pressure swing distillation, etc. are far away, so as to achieve the effect of ensuring purity, improving product purity and yield, and efficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

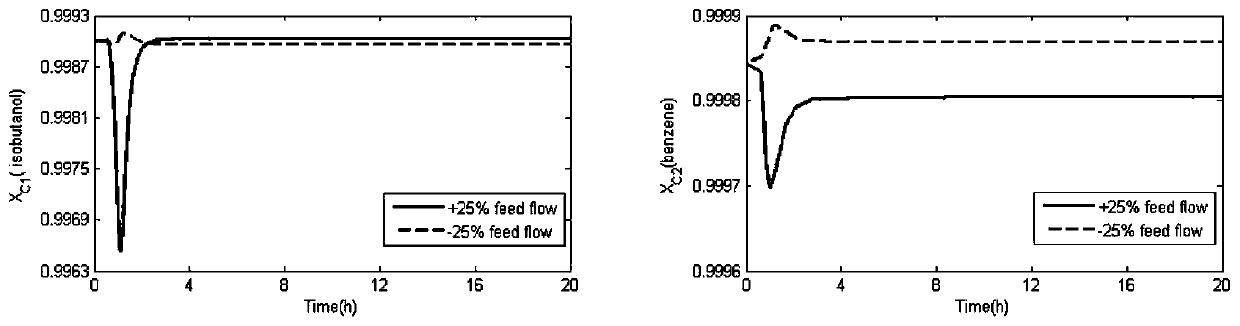

[0037] After the initial operation of each controller, the set value is automatically input, and the set value is used to determine the range of the intermediate value, and the closed loop is used as a test method. Add ± 25% feed flow perturbation on the basis of the initial steady-state process, that is, after the feed flow is 100kmol / h (20% isobutanol, containing 80% benzene) after the stable operation of the process, add +25% ( 125 kmol / h) flow disturbance and -25% (75 kmol / h) flow disturbance.

[0038] After the disturbance was added, the purity of isobutanol at the bottom of the atmospheric column and the purity of benzene at the top of the high-pressure column were recorded to test the control performance of the dynamic control system. The dynamic response diagram of the flow disturbance is attached figure 2 As shown, the solid line is +25% feed flow disturbance, and the dashed line is -25% feed flow disturbance.

[0039] When the feed is disturbed by ±25%, the concen...

Embodiment 2

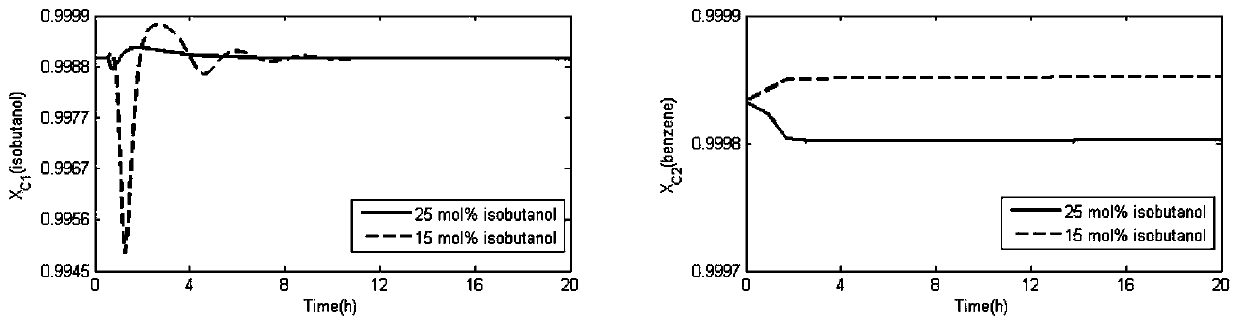

[0041] After the initial operation of each controller, the set value is automatically input, and the set value is used to determine the range of the intermediate value, and the closed loop is used as a test method. Add ±25% feed composition disturbance on the basis of the initial steady-state process, that is, add isobutanol+ 25% (25% isobutanol, containing 75% benzene) composition perturbation and isobutanol-25% (15% isobutanol, containing 85% benzene) composition perturbation.

[0042] After the disturbance was added, the purity of isobutanol at the bottom of the atmospheric column and the purity of benzene at the top of the high-pressure column were recorded to test the control performance of the dynamic control system. The dynamic response diagram of the flow disturbance is attached image 3 As shown, the solid line is +25% feed composition disturbance, and the dashed line is -25% feed composition disturbance.

[0043] When a disturbance of ± 25% is added to the feed compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com