A kind of PVC heat stabilizer and preparation method thereof

A heat stabilizer and stabilizer technology, which is applied in the field of PVC heat stabilizer and its preparation, can solve the problems of poor heat stability of PVC, and achieve the effects of high heat stabilization efficiency, cost reduction, and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

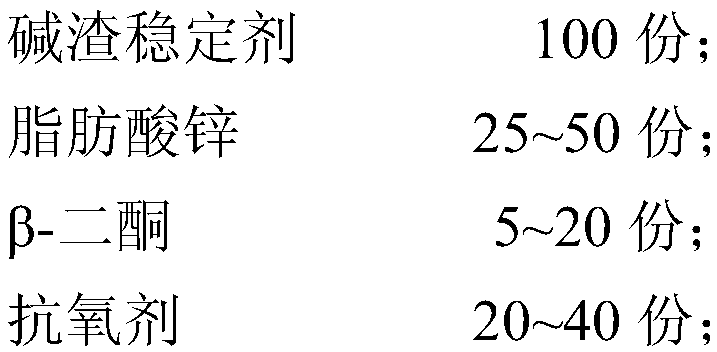

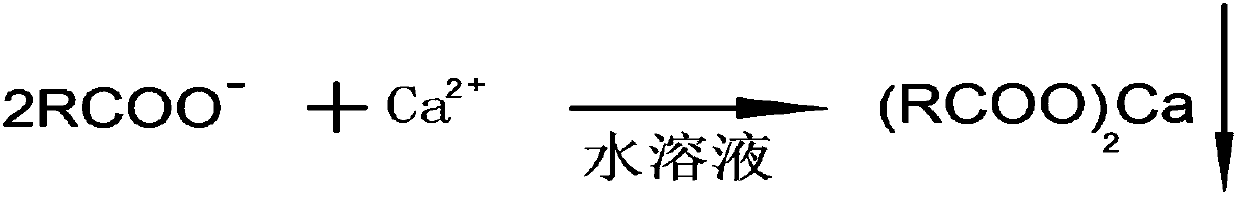

Method used

Image

Examples

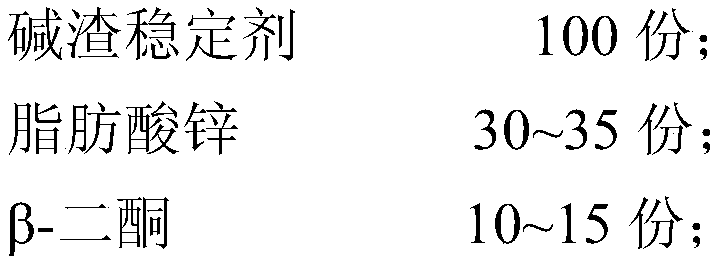

Embodiment 1

[0042] A PVC heat stabilizer, the components of which are: 100 parts of alkali slag stabilizer; 33 parts of fatty acid zinc; 11 parts of β-diketone; 28 parts of phosphite.

[0043] The steps of the specific preparation method are as follows:

[0044] (1) Take the waste liquid after the alkali production by the ammonia-soda method, after precipitation, remove the lower layer of slurry-like waste residue, add it dropwise in the aqueous sodium stearate solution, continue to stir, and carry out the double decomposition reaction. After the reaction is over, the reaction product is press-filtered and washed with water and drying to obtain the alkali slag stabilizer;

[0045] (2) The alkali slag stabilizer is mixed with zinc stearate, β-diketone and phosphite to obtain a PVC heat stabilizer.

[0046] The waste liquid chemical composition after the ammonia-soda method alkali production of certain alkali factory involved in the present embodiment is as follows (in the volume of waste li...

Embodiment 2

[0054] Except that the mass fraction of calcium stearate in the alkali slag stabilizer used in this embodiment is 95%, the dosage and preparation method of the remaining components are exactly the same as those in Example 1.

Embodiment 3

[0058] Except that the mass fraction of calcium stearate in the alkali slag stabilizer used in this embodiment is 85%, the dosage and preparation method of the remaining components are exactly the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com