Manufacturing method of electrochromic cloth

An electrochromic material and electrochromic technology, which are applied in nonlinear optics, instruments, optics, etc., can solve the problems of metal fabrics that are not resistant to corrosion, prone to short circuits, and heavy and heavy, and achieve a simple, easy-to-operate and easy-to-use preparation method. Large-scale production, strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

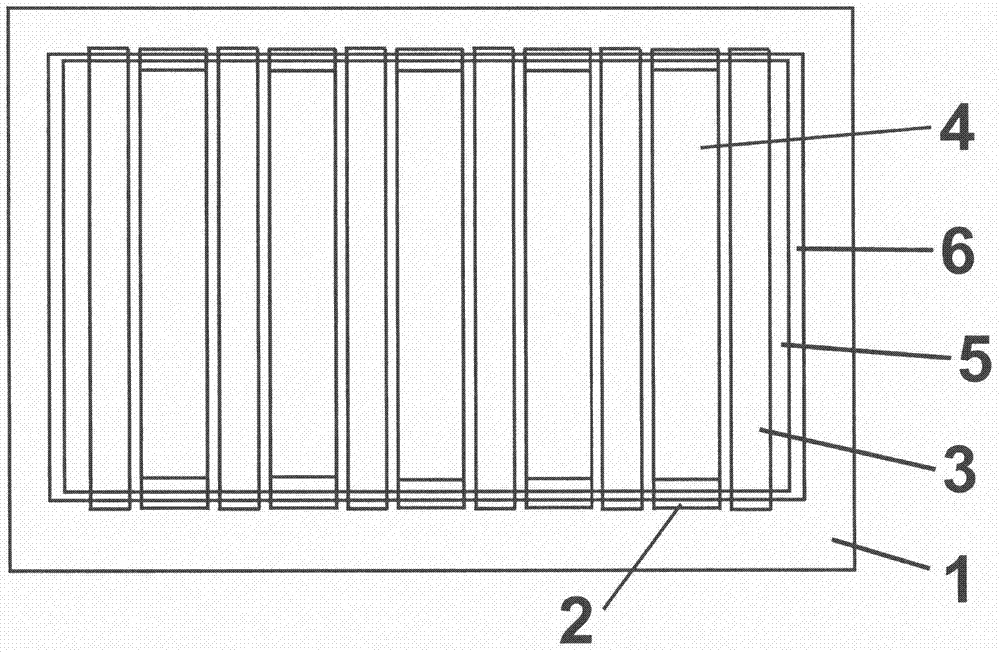

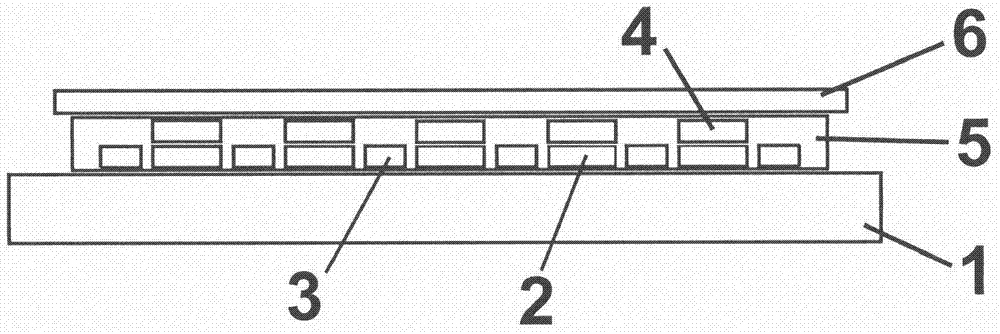

[0022] figure 1 is the plane structure diagram of the electrochromic cloth device, figure 2 is the side structure diagram of the electrochromic cloth device. Spray the ITO conductive paste on the synthetic fiber cloth 1 according to the template, and bake at 100°C for 5 minutes to obtain a wide ITO film 2 and a narrow ITO film 3 in parallel intervals, as the electrodes of the electrochromic device, and each wide ITO film The width of the electrodes is 3-5 millimeters, the width of each narrow ITO film electrode is 1-2 millimeters, and the interval between the ITO films is less than 1 millimeter. Then, the electrochromic material 4 is sprayed on the wide ITO film 2 and baked at 80° C. for 5 minutes. Finally, the electrolyte 5 is sprayed on the cloth covering the ITO film electrodes 2, 3 and the electrochromic material 4, and covered with a thin transparent polyethylene film 6, and cured under a 365 nm ultraviolet lamp for 5 minutes to obtain an electrochromic cloth device. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com