Tire X-ray defect/flaw detection method based on deep convolutional neural network

A convolutional neural network and deep convolution technology, applied in the field of tire X-ray defect detection based on deep convolutional neural network, can solve the problems of strong contingency, inability to accurately detect tire defects, and low reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The implementation of the present application will be described in detail below with reference to the accompanying drawings and examples, so as to fully understand and implement the implementation process of how the present application uses technical means to solve technical problems and achieve technical effects.

[0063] A tire X-ray defect detection method based on a deep convolutional neural network, the steps are as follows:

[0064] S1. Image preprocessing: see image 3 , to sharpen the original image. The original picture is not clear. After sharpening, the grain of the picture is clearer and the defect is more obvious.

[0065] S2. Data cleaning: cutting out the existing tire defect pictures, cutting out the defect part in the defect picture, as a negative sample; cutting out the normal part in the picture, as a positive sample.

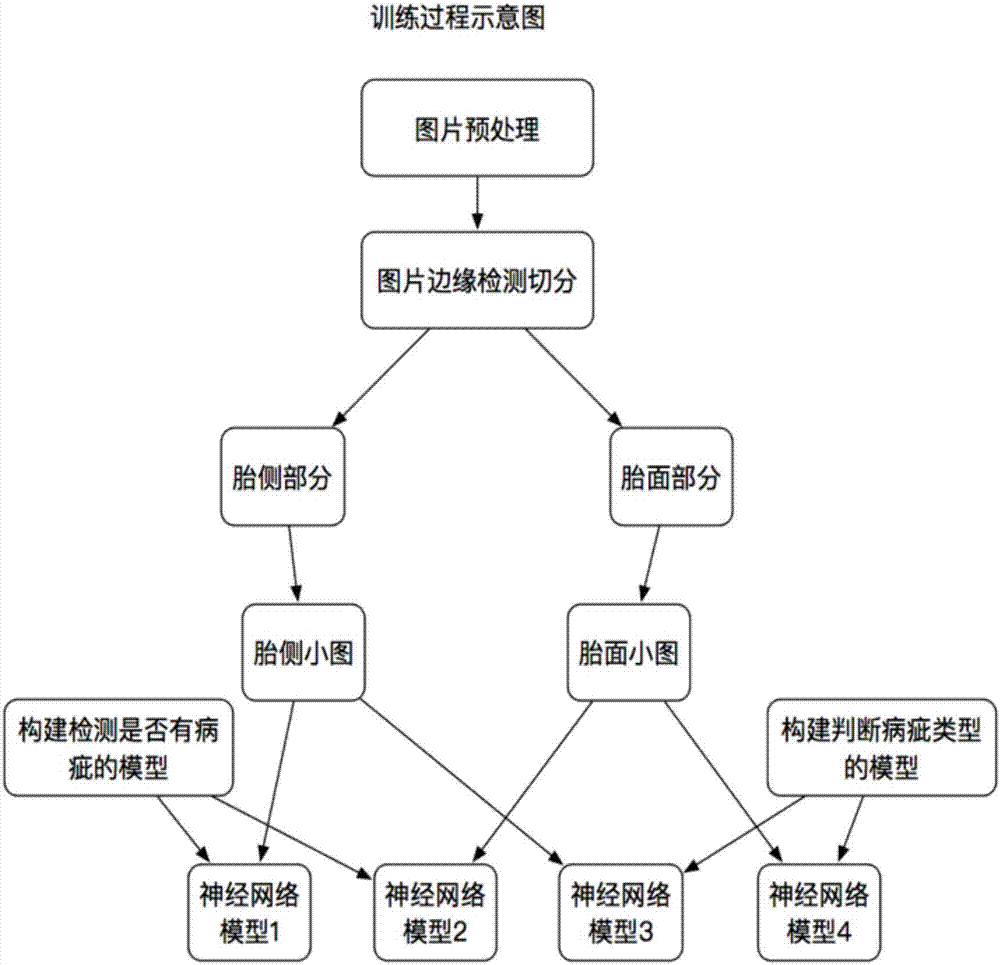

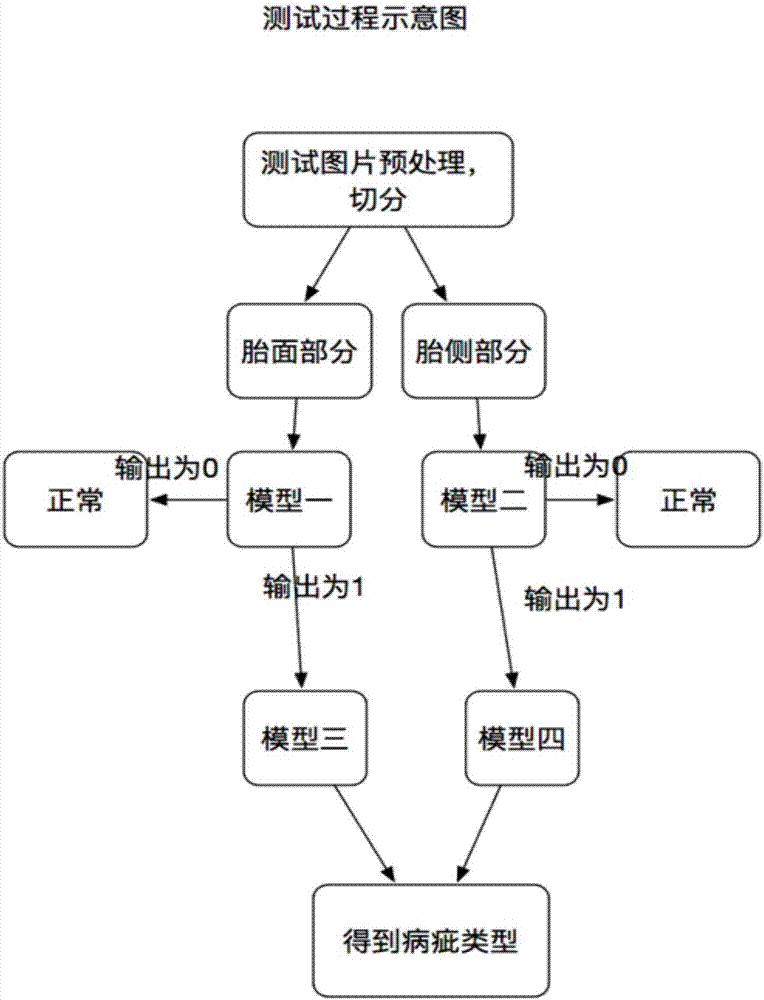

[0066] S3. Design and training of convolutional neural network: see figure 1 , design four convolutional neural network models, tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com