An integrated automatic floating and sinking machine with circular symmetrical structure

A ring-shaped symmetrical and integrated technology, applied in chemical instruments and methods, solid separation, preparation of samples for testing, etc. The effect of reducing potential hazards and greatly improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

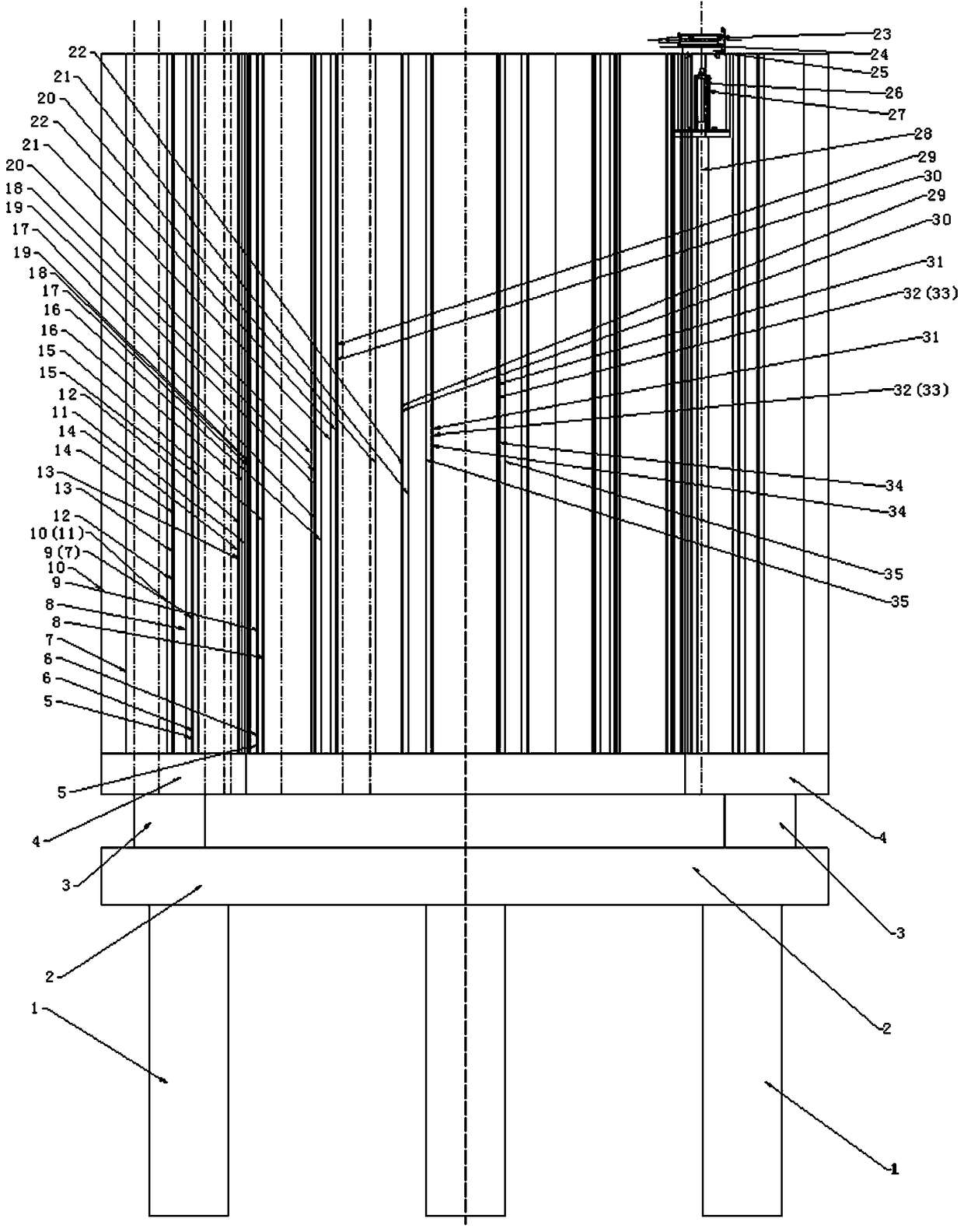

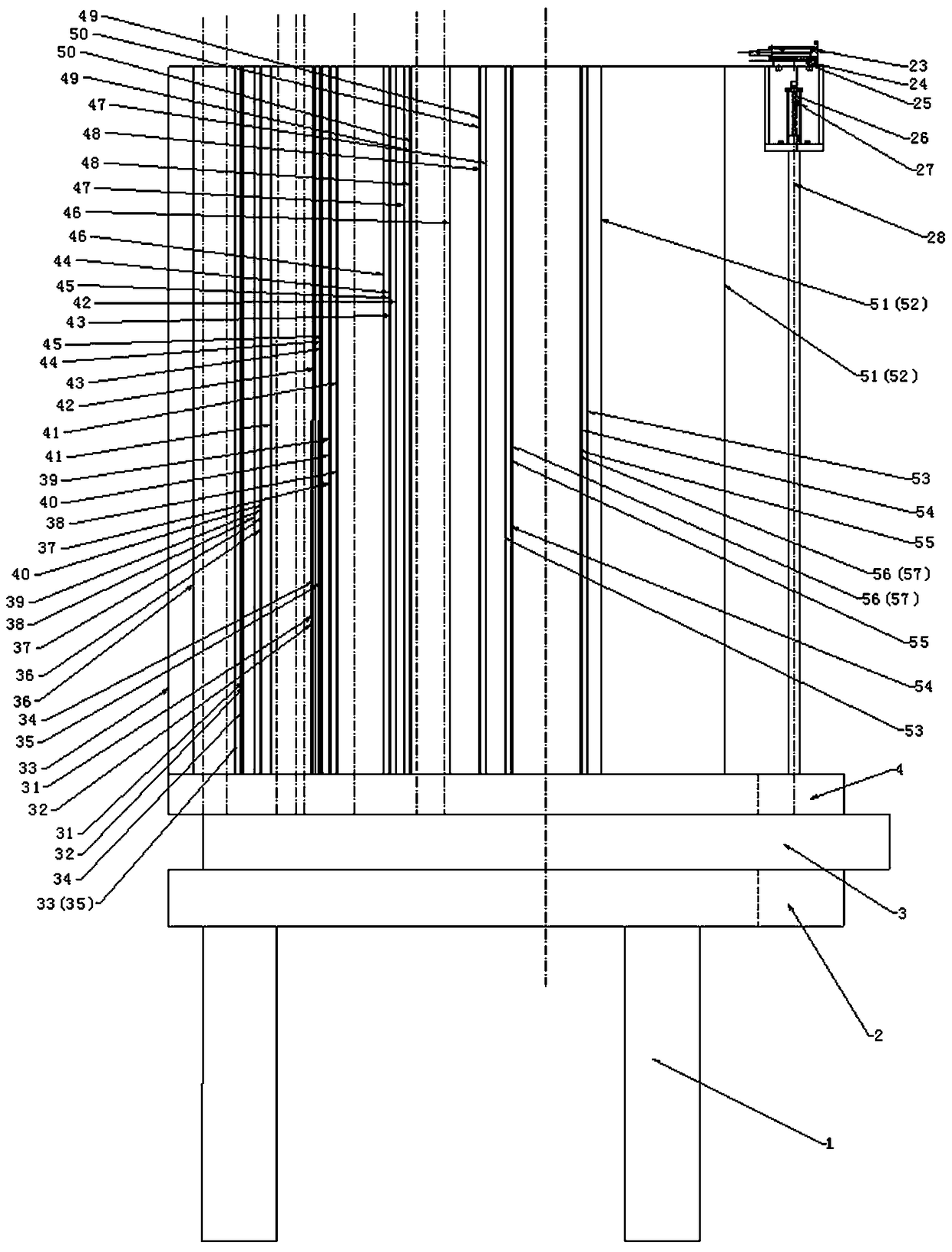

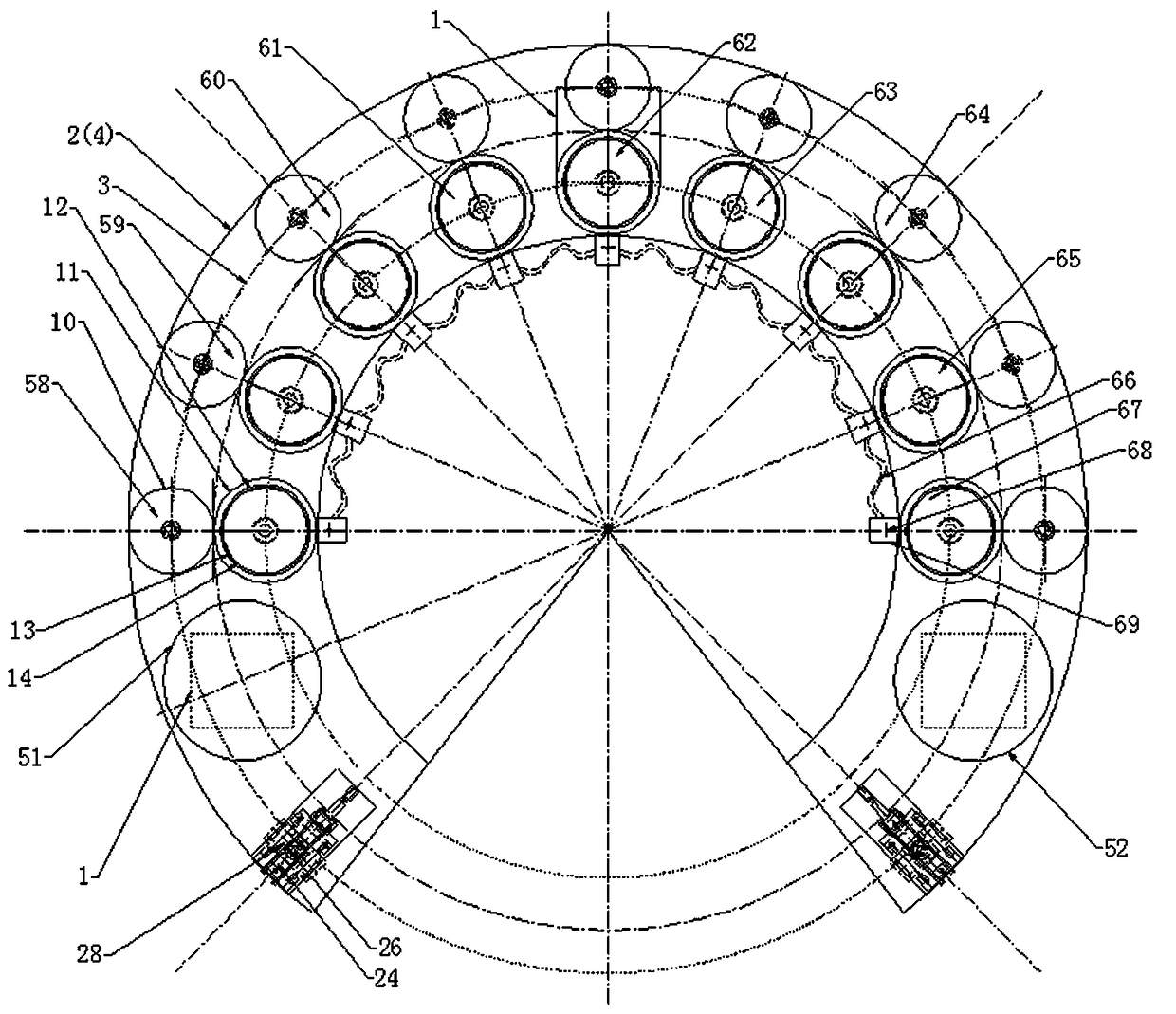

[0033] Such as figure 1 , 2 , 3, the circular symmetric structure integrated automatic sinking machine of the present invention adopts a circular symmetric mechanical structure arrangement, and it includes a coal sample arranged at the left end of the circular mechanical structure composed of the swivel disc guide rail 3 and the complete machine swivel disc 4. The pretreatment tank 51, the gangue collection tank 52 at the right end, and the cylinder groups that are respectively arranged on the left side of the coal sample pretreatment tank 51 and the right side of the gangue collection tank 52 are composed of a horizontal moving cylinder 24 and a vertical moving cylinder 26 , between the right side of the coal sample pretreatment tank 51 and the left side of the gangue collection tank 52, along the inner side of the annular mechanical structure, several densit...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap