Rotating plate type indexing sliding table multi-station drilling and tapping machine

A turntable, multi-station technology, which is applied to metal processing machinery parts, positioning devices, manufacturing tools, etc., can solve the problems of low production efficiency and difficulty in ensuring hole position accuracy, so as to improve production efficiency, solve synchronous drilling and Tapping, the effect of ensuring machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

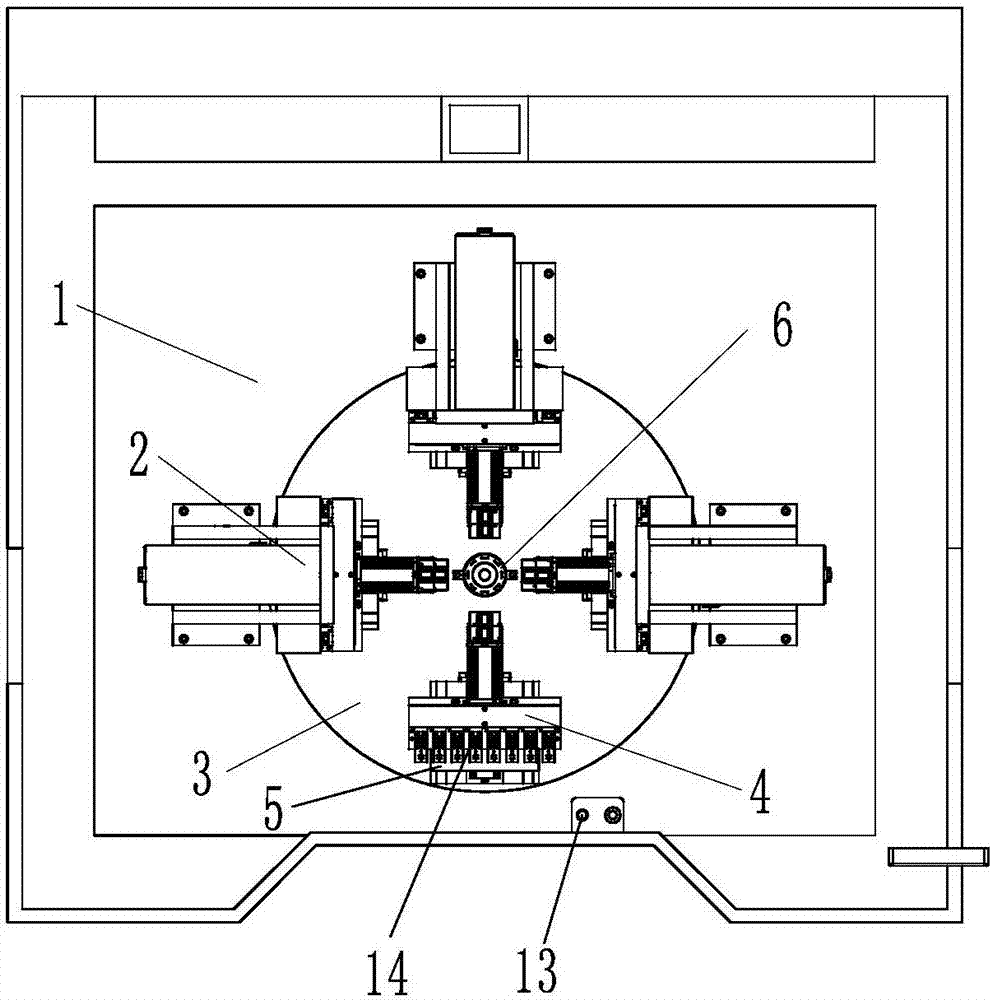

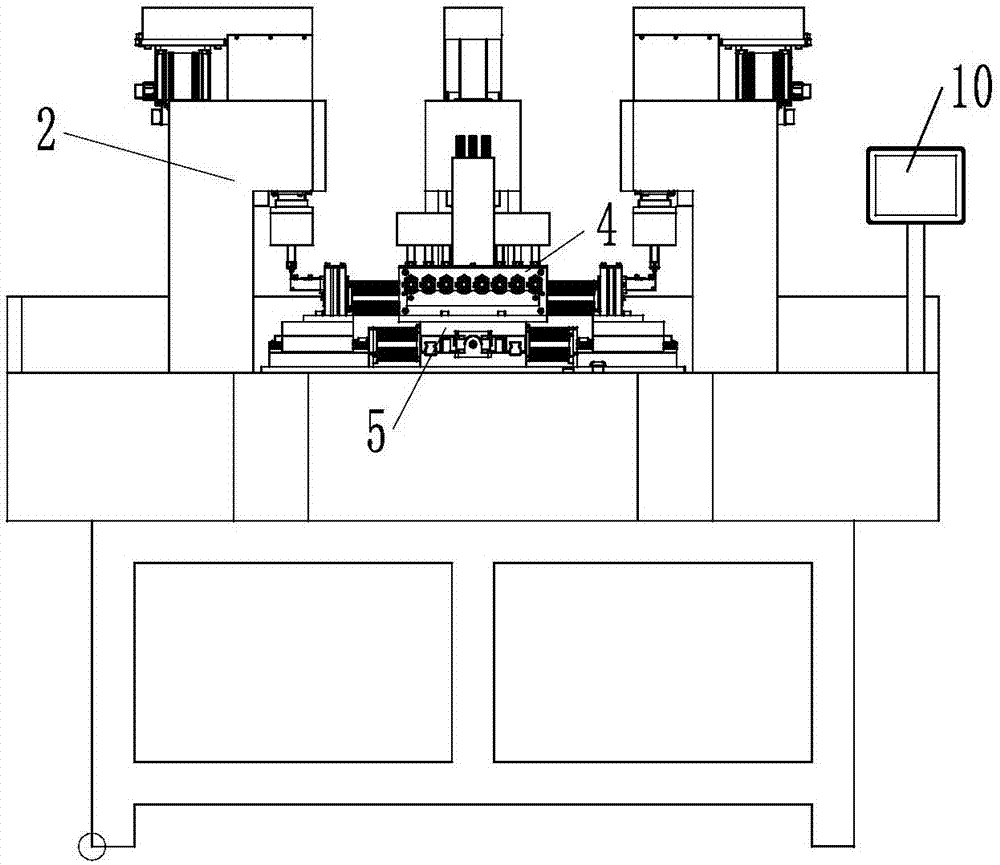

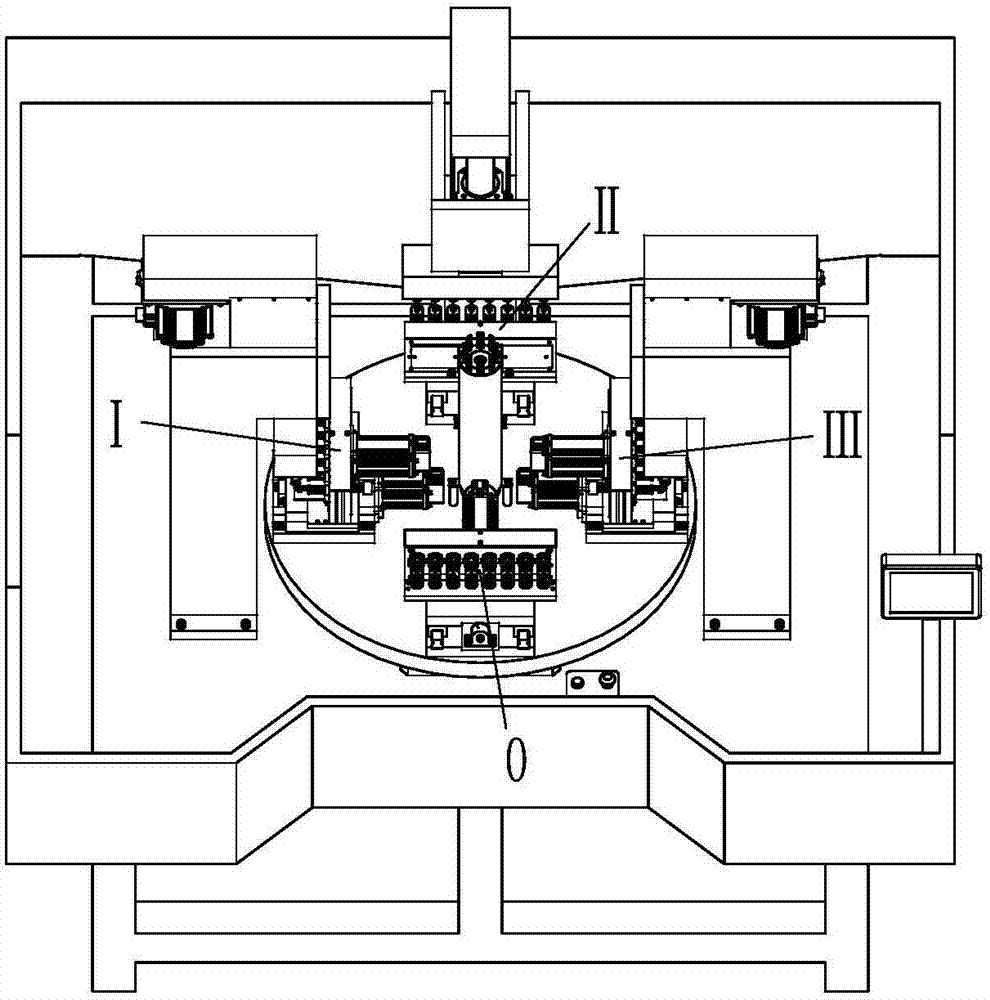

[0024] to combine figure 1 — Figure 7 Shown, a rotary table indexing slide table multi-station drilling and tapping machine, mainly by the frame table 1, numerical control drilling and tapping cutting unit 2, rotating disk 3, clamping body 4, servo slide table 5, electric slip ring 6, Divider 7, first servo motor 8, second servo motor 9, display screen 10, intermediate transmission mechanism 11, start button 13, workpiece positioning device 14 and so on.

[0025] The divider 7, the start-stop station O and three CNC drilling and cutting units 2 are arranged on the frame table 1, and each CNC drilling and cutting unit 2 is equipped with a multi-axis device to realize the purpose of synchronously processing multiple workpieces. Multi-axis devices are widely used in drilling and tapping machines to improve processing efficiency.

[0026] The rotating dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com