Circuit board edging system

A circuit board and edge grinding technology, which is applied to machine tools, grinders, grinding racks, etc. suitable for grinding workpiece edges, can solve the problems of circuit board production line length, etc., and achieve the effect of reducing the floor space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

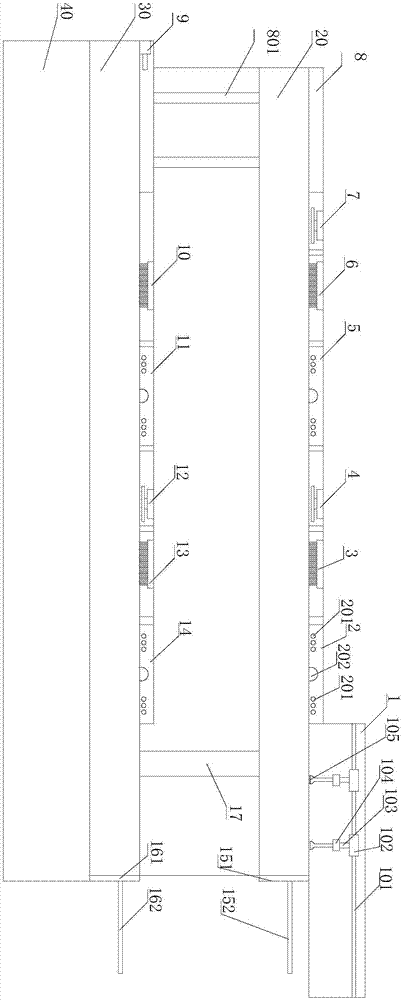

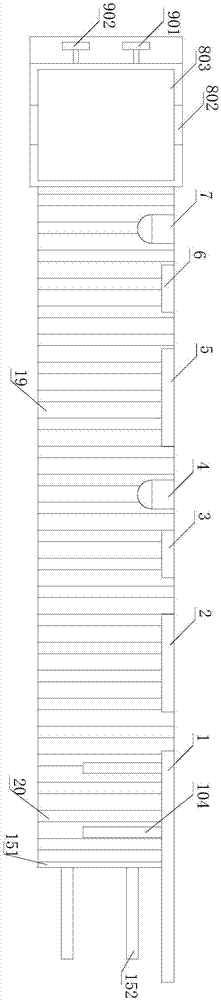

[0023] Such as Figure 1-2 As shown, a circuit board edging system includes a frame, a conveying device 19, a feeding device 1, an edging device, a rotating device, a dust cleaning device, a pushing device 9, and a control cabinet 40. The edging device includes a first grinding Edge device, second edging device, third edging device, fourth edging device, rotating device includes first rotating device 4, second rotating device 7, third rotating device 12, dust cleaning device includes first dust cleaning device Device 3 , second dust removal device 6 , third dust removal device 10 , and fourth dust removal device 13 .

[0024] The conveying device 19 is arranged on the frame, and in this solution, the conveying device is a conveying roller 19 . The rack includes an upper rack 20 and a lower rack 30 .

[0025] Discharging device 1, first edging device 2, first dust cleaning device 3, first rotating device 4, second edging device 5, second dust cleaning device 6, second rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com