Rotating disc type scrap iron wafering equipment

A turntable-type, iron filings technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of low production efficiency, achieve the effects of improving production efficiency, reducing labor intensity, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

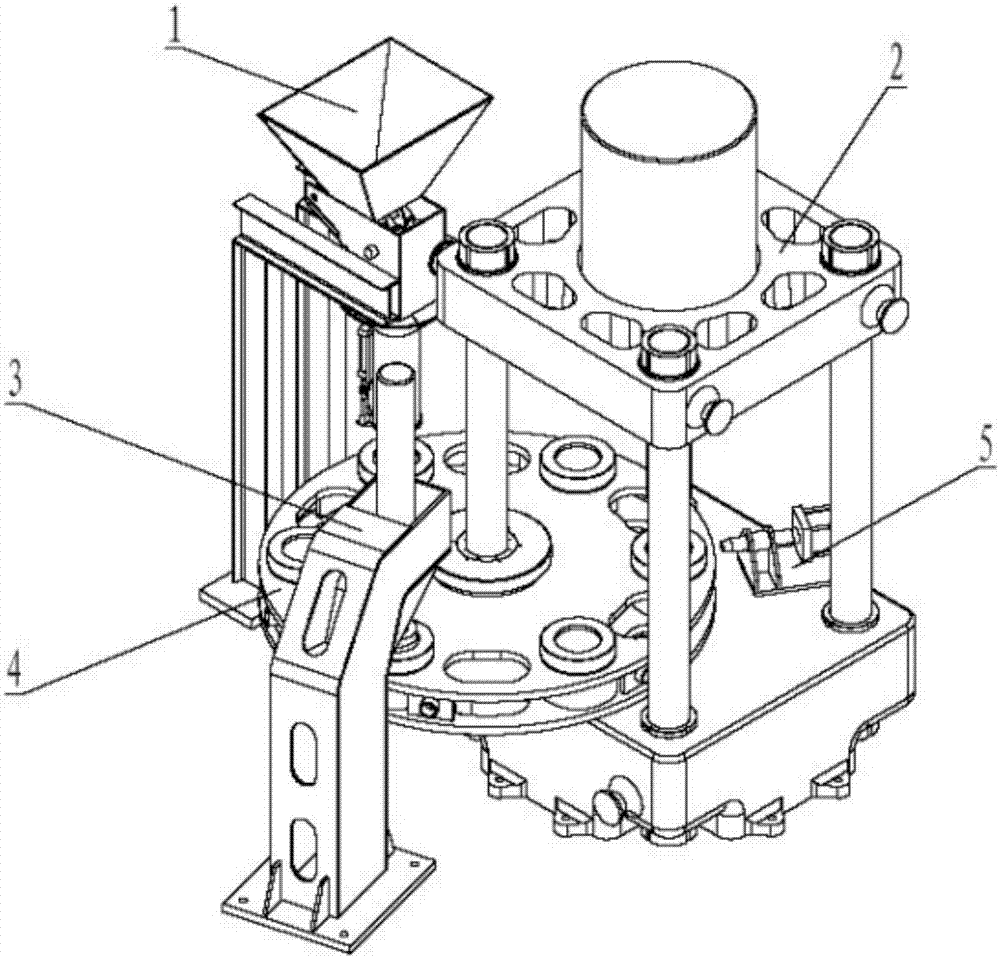

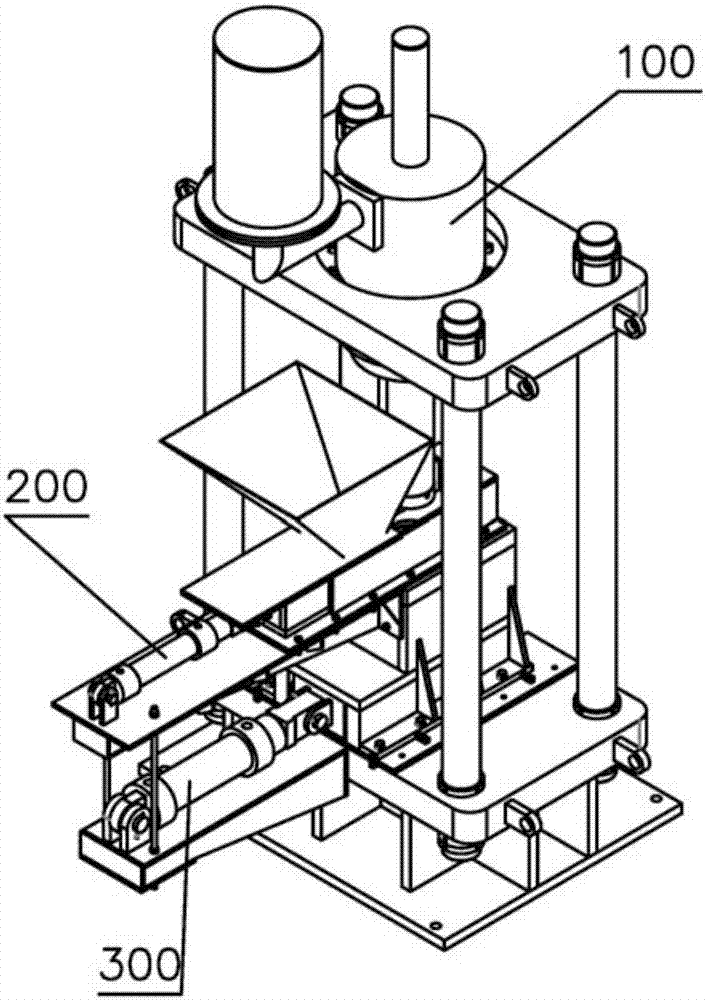

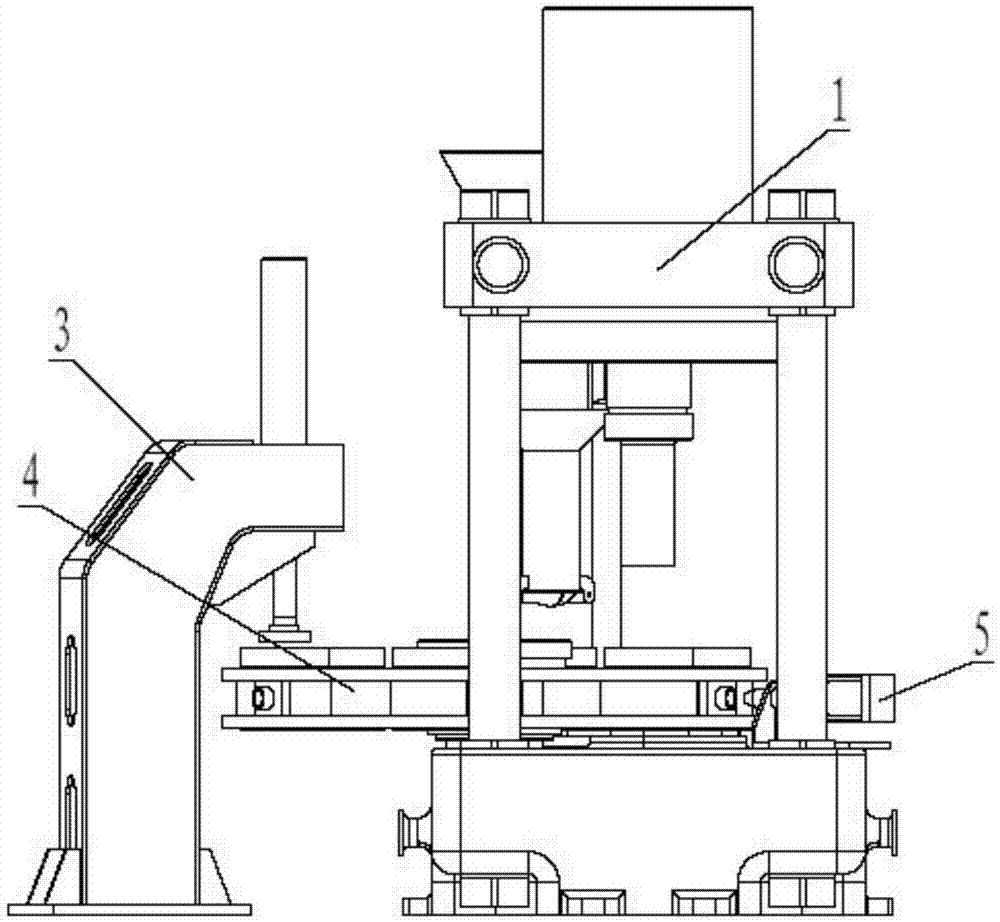

[0038] Such as figure 1As shown, the present embodiment provides a turntable type iron filings pressing equipment, including a feeding mechanism 1, a pressing mechanism 2, a discharging mechanism 3, a turntable mechanism 4, a mechanical positioning mechanism 5 and a frame; the turntable mechanism 4 is set In the middle of the frame, a plurality of molds 4-4 are evenly arranged on the turntable mechanism 4 along the circumferential direction, and the feeding mechanism 1, the pressing mechanism 2 and the discharging mechanism 3 are arranged on the machine on the shelf and distributed around the turntable mechanism 4 in turn, the feeding mechanism 1, the pressing mechanism 2 and the discharging mechanism 3 are respectively facing one of the molds 4-4; the mechanical positioning mechanism 5 is set On the side of the turntable mechanism 4.

[0039] In this specific example, if figure 1 And as shown in 2-11, the bottom of the structure of the turntable 4-3 is provided with a wea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com