Embossing equipment for zip-lock bag

A self-sealing bag and embossing technology, which is used in bag making operations, paper/cardboard containers, container manufacturing machinery, etc., can solve the problems of oil pollution on the wafer surface and secondary pollution of wafers, and achieve high work efficiency, high degree of automation, principle Easy to understand effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

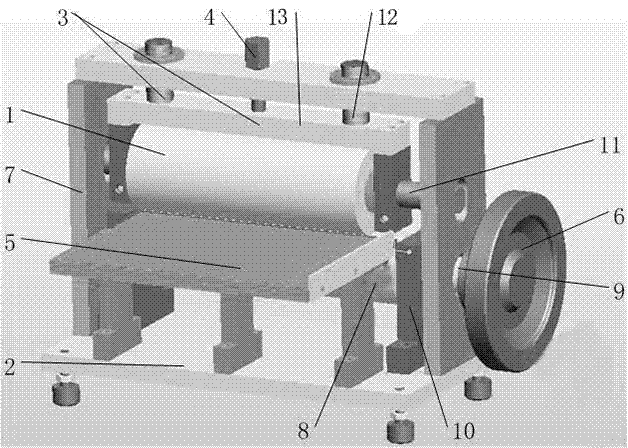

[0017] Such as figure 1 As shown, a self-sealing bag embossing equipment, which includes a frame 7, embossing roller 1, slide rail mechanism 3, spacing adjustment mechanism 4, conveying platform 5 and transmission wheel 6, the bottom of the frame 7 is provided with a base 2 , the top of the base 2 is fixedly installed with the active roller 8, the active roller 8 is installed on the frame 7 through the shaft A9, one end of the shaft A9 is fixedly installed with the drive wheel 6, and the left and right sides of the active roller 8 are provided with supports Plate 10, a conveying platform 5 is installed on the support plate 10, the conveying platform 5 is located between the driving roller 8 and the embossing roller 1, the upper surface and the lower surface of the conveying p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com