Soil insensitive polycarboxylic acid water reducer and preparation method thereof

A technology of polycarboxylate and water reducer, applied in the preparation of non-soil-sensitive polycarboxylate water-reducer, non-soil-sensitive polycarboxylate water-reducer, concrete admixture, polycarboxylate water-reducer In the field of preparation, it can solve the problems of soil sensitivity of sand and gravel raw materials, and achieve the effect of solving soil sensitivity, short production cycle and coordinating reactivity rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

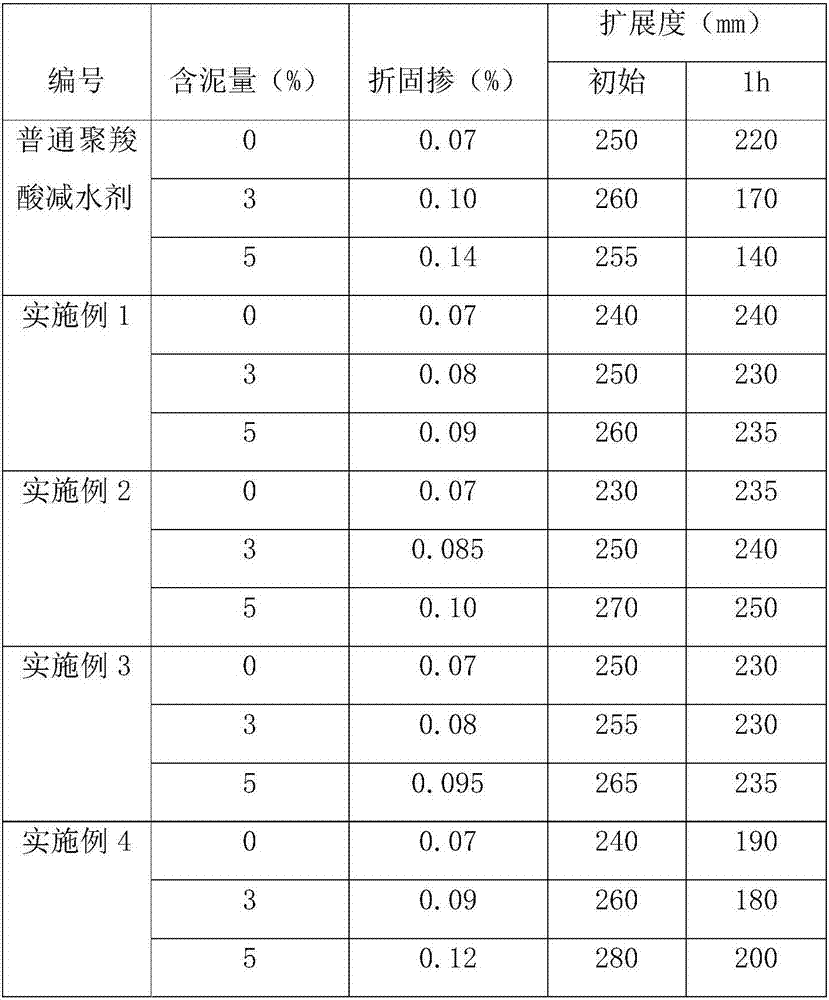

Examples

Embodiment 1

[0016] Embodiment 1: The non-soil-sensitive polycarboxylate water reducer of the present invention is based on 4-hydroxybutyl vinyl ether macromonomer, unsaturated carboxylic acid, unsaturated sulfonate, unsaturated ester small monomer Comonomer, made by copolymerization reaction with initiator and chain transfer agent as molecular regulator, the mass ratio of each component is: 4-hydroxybutyl vinyl ether: unsaturated carboxylic acid: unsaturated sulfonate Acid acid: unsaturated ester small monomer: initiator: chain transfer agent: deionized water=72:4:6:16:1:1.5:80.

[0017] The preparation method of the non-soil-sensitive polycarboxylate water reducer includes the following process steps: add 72 parts of 4-hydroxybutyl vinyl ether with a molecular weight of 2400 and 40 parts of deionized water to 500ml according to the above mass ratio In a three-necked flask, heat and start the stirrer to heat up, and at the same time, 1 part of initiator, i.e. ammonium persulfate and 1.5 p...

Embodiment 2

[0018] Embodiment 2: The non-soil-sensitive polycarboxylate water reducer of the present invention is based on 4-hydroxybutyl vinyl ether macromonomer, unsaturated carboxylic acid, unsaturated sulfonate, unsaturated ester small monomer Comonomer, made by copolymerization reaction with initiator and chain transfer agent as molecular regulator, the mass ratio of each component is: 4-hydroxybutyl vinyl ether: unsaturated carboxylic acid: unsaturated sulfonate Acid acid: unsaturated ester small monomer: initiator: chain transfer agent: deionized water=120:4.5:8:20:1.5:2:95.

[0019]The preparation method of the non-soil-sensitive polycarboxylate water reducer includes the following process steps: add 120 parts of 4-hydroxybutyl vinyl ether with a molecular weight of 4000 and 60 parts of deionized water into 500ml In a three-necked flask, heat and start the stirrer to heat up, and at the same time, 1.5 parts of initiator, namely ammonium persulfate, and 2 parts of chain transfer ag...

Embodiment 3

[0020] Embodiment 3: The non-soil-sensitive polycarboxylate water reducer of the present invention is based on 4-hydroxybutyl vinyl ether macromonomer, unsaturated carboxylic acid, unsaturated sulfonate, unsaturated ester small monomer Comonomer, made by copolymerization reaction with initiator and chain transfer agent as molecular regulator, the mass ratio of each component is: 4-hydroxybutyl vinyl ether: unsaturated carboxylic acid: unsaturated sulfonate Acid acid: unsaturated ester small monomer: initiator: chain transfer agent: deionized water=72:4:8:12:1.5:0.5:80.

[0021] The preparation method of the non-soil-sensitive polycarboxylate water reducer includes the following process steps: add 72 parts of 4-hydroxybutyl vinyl ether with a molecular weight of 2400 and 40 parts of deionized water to 500ml according to the above mass ratio In a three-necked flask, heat and start the stirrer to raise the temperature, and at the same time, dissolve 0.1 part of initiator, namely ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com