Preparation method of spaceflight projectile body heat shielding structure

A heat-resistant and projectile technology, applied in the direction of offensive equipment, self-propelled bombs, projectiles, etc., can solve the problems of long cycle, high cost, and high operating threshold, and achieve the effect of low threshold, light weight, and guaranteed production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

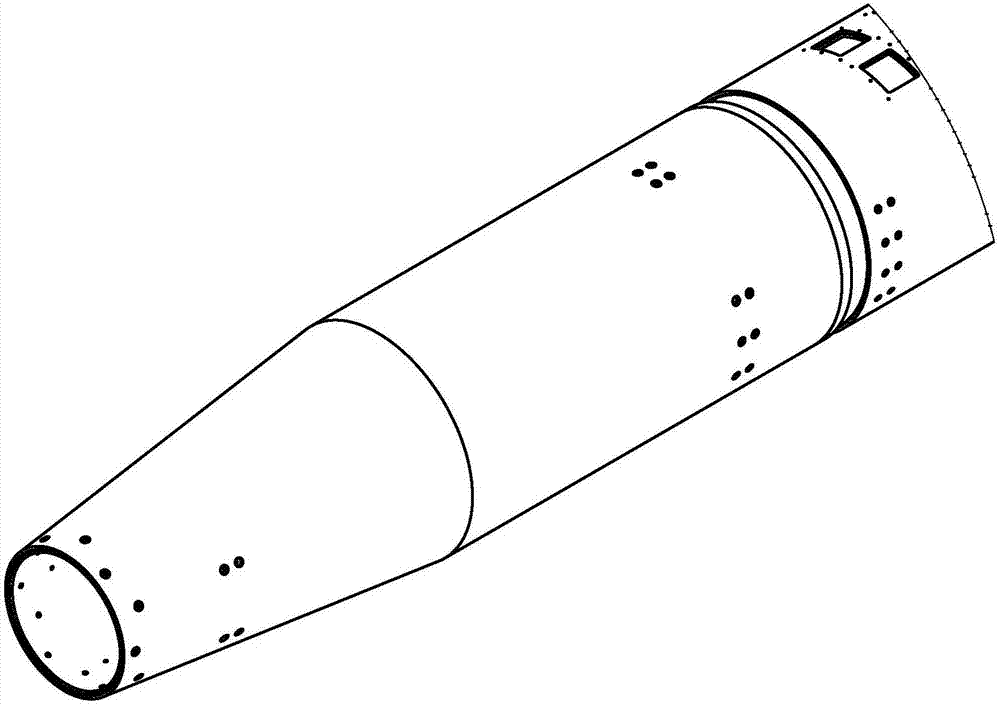

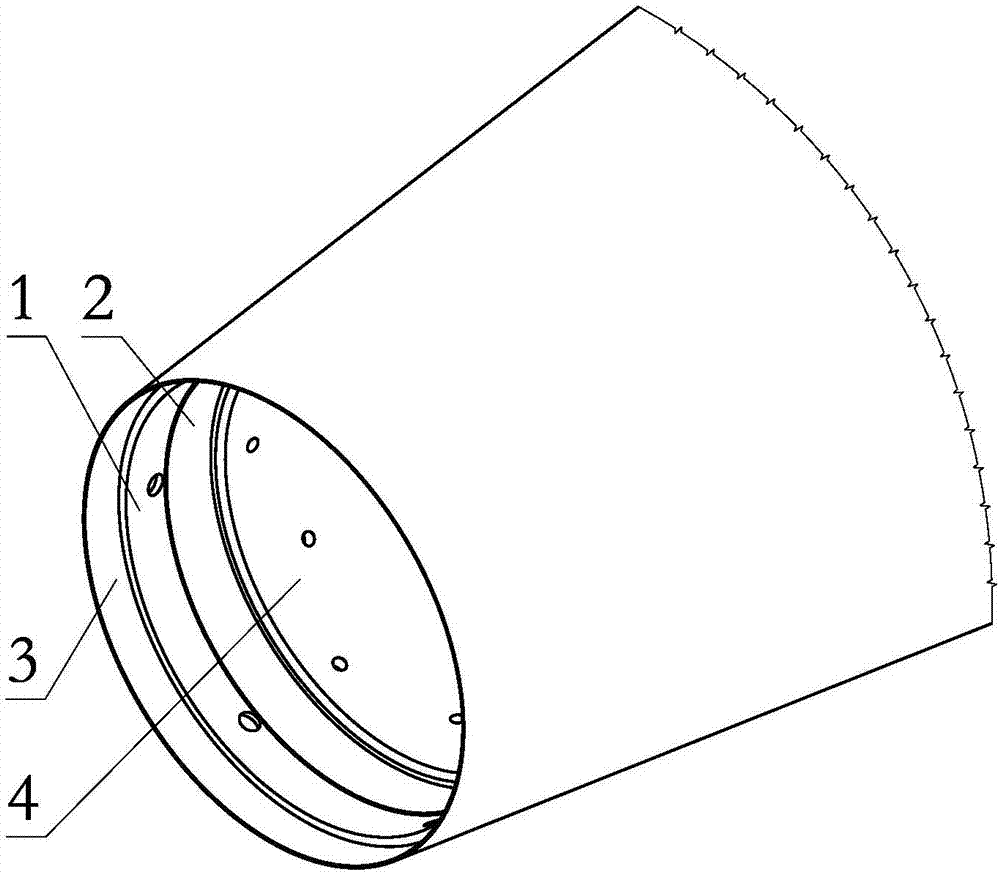

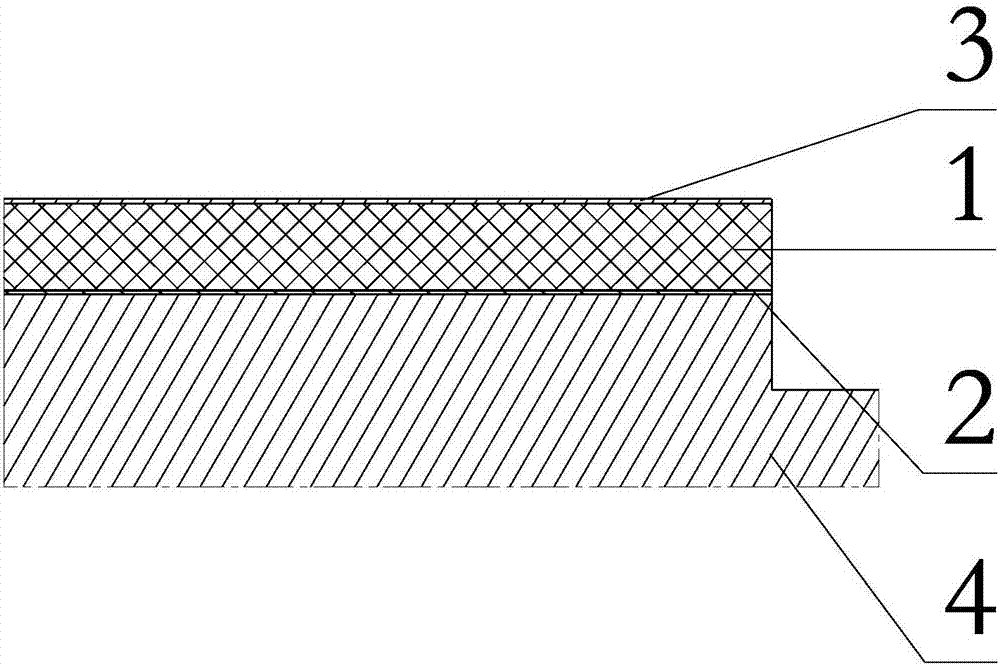

[0037] In this embodiment, the heat-proof structure of the aerospace projectile combines figure 1 , consisting of a heat-resistant layer body 1, a high-temperature structural adhesive layer 2, a heat-resistant coating 3 and a metal cabin section 4, the heat-resistant layer body 1 is bonded together with the metal cabin section 4 through a high-temperature structural adhesive layer 2, and the anti- The outer surface of the thermal layer body 1 is sprayed with a heat-resistant coating 3 .

[0038] Specifically in this embodiment, after the heat-proof layer body 1 is paved and solidified, it is cut into sections after being added by an external circular machine. The high-temperature structural adhesive layer 2 is a liquid adhesive with poor fluidity. The heat-resistant coating is 3 minutes It is an inner coating and an outer coating, and the metal cabin section 4 is a metal part.

[0039] combine figure 2 , the heat-proof layer body 1 is a ring-shaped / conical thin-walled struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com