High-voltage direct-current cable outdoor terminal

A high-voltage direct current and cable technology, which is applied to the installation of cable terminals, cable accessories, and cables, can solve the problems of pollution flashover, high electric field strength of insulating bushings, and potential safety hazards, so as to reduce the probability of pollution accumulation and avoid Pollution flashover or breakdown, the effect of uniform electric field intensity distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

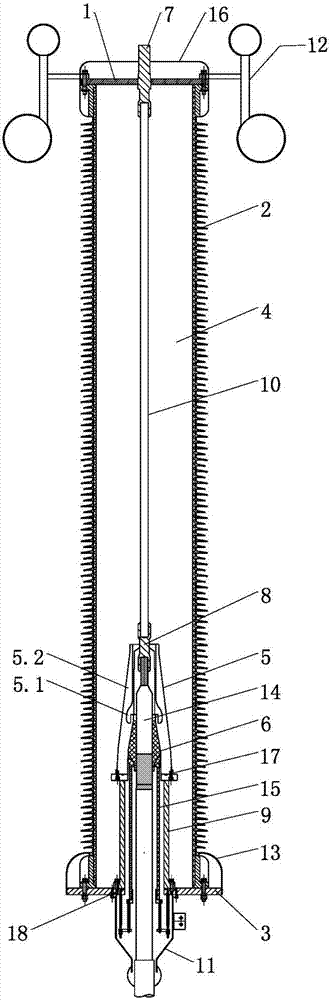

[0033] A high-voltage DC cable outdoor terminal, such as figure 1 As shown, it includes upper flange 1, insulating sleeve 2, lower flange 3, insulating filler 4, cable 14, lower conductor lead-out rod 8, connecting conductor 10, upper conductor lead-out rod 7, stress cone 6, insulating sleeve 2 is a hollow cylindrical structure, the upper end surface and the lower end surface of the insulating sleeve 2 are respectively connected with the lower end surface of the upper flange 1 and the upper end surface of the lower flange 3 to form a sealed chamber 1, which is filled with insulating filler Agent 4, the inner bottom of sealed chamber 1 is provided with sealed chamber 2, the connecting conductor 10 is arranged in sealed chamber 1, the lower end surface of connecting conductor 10 is connected to the top of sealed chamber 2 through the lower conductor lead-out rod 8, and the lower conductor lead-out rod 8 extends To the inside of the sealed chamber 2, the upper end surface of the ...

Embodiment 2

[0036] According to the outdoor terminal of a high-voltage DC cable described in Embodiment 1, the difference is that:

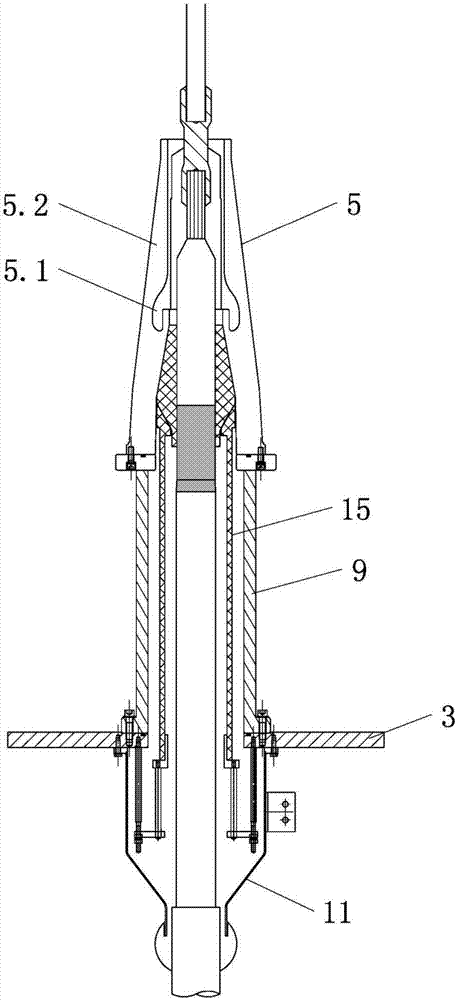

[0037] The sealed chamber 2 includes an inner insulating sleeve 5 and a connecting seat 9. The connecting seat 9 is a hollow cylindrical structure. The end face is connected to the upper end face of the connecting seat 9, the lower end face of the connecting seat 6 is connected to the lower flange 3, and the inner insulating sleeve 5 is provided with an internal shielding electrode 5.1, which is a hollow cylindrical structure.

[0038] The advantage of the design here is that the internal shielding electrode 5.1 provided inside the internal insulating sleeve 5 can even out the electric field distribution in the adjacent parts, so that the electric field intensity of the stress cone 6, the internal insulating sleeve 5, the insulating filler 4, and the insulating sleeve 2 is uniform The distribution reduces the electric field intensity on the surface of the in...

Embodiment 3

[0043] According to the outdoor terminal of a high-voltage DC cable described in Embodiment 1, the difference is that:

[0044]The outdoor terminal of the high-voltage DC cable also includes a tailpipe 11 and a compression device 15. The lower part of the stress cone 6 is provided with a compression device 15. The bottom of the lower flange 3 is connected to the tailpipe 11. The inner insulating sleeve 5, the connecting seat 9 and the tailpipe 11 form a seal. room two, such as figure 2 As shown, the cable 14 passes through the tail pipe 11 and enters the sealed chamber two.

[0045] The advantage of the design here is that the uniform compressive force applied on the stress cone 6 by the compression device 15 increases the surface pressure strength between the stress cone 6 and the cable 14, reduces the air gap at the interface between the stress cone 6 and the cable 14, The generation of partial discharge is reduced, and the electrical stability of the outdoor terminal is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com