Recycled aggregate composite cavity type water storage brick

A technology of recycled aggregates and water storage bricks, which is applied in the field of brick materials for construction, can solve the problems of large exposed surface of grass planting bricks, low turf survival rate, and resistance to trampling, and achieve good economic benefits and ecological environmental benefits, beautification The effect of environment and temperature regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings.

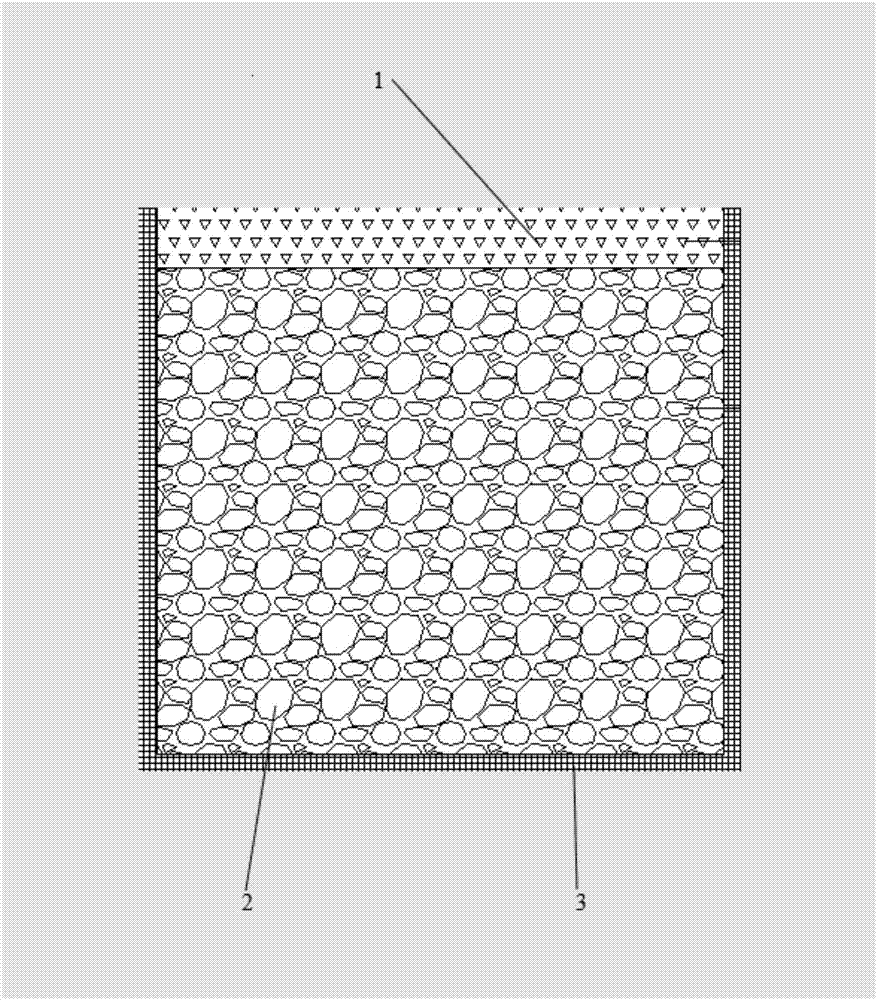

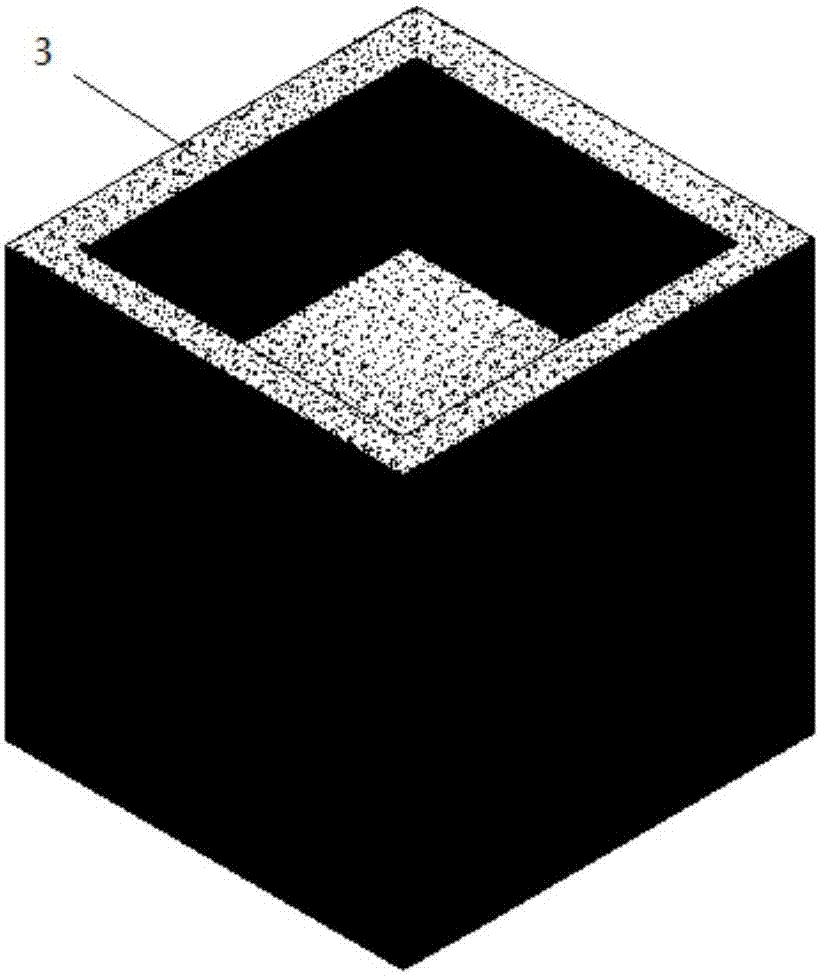

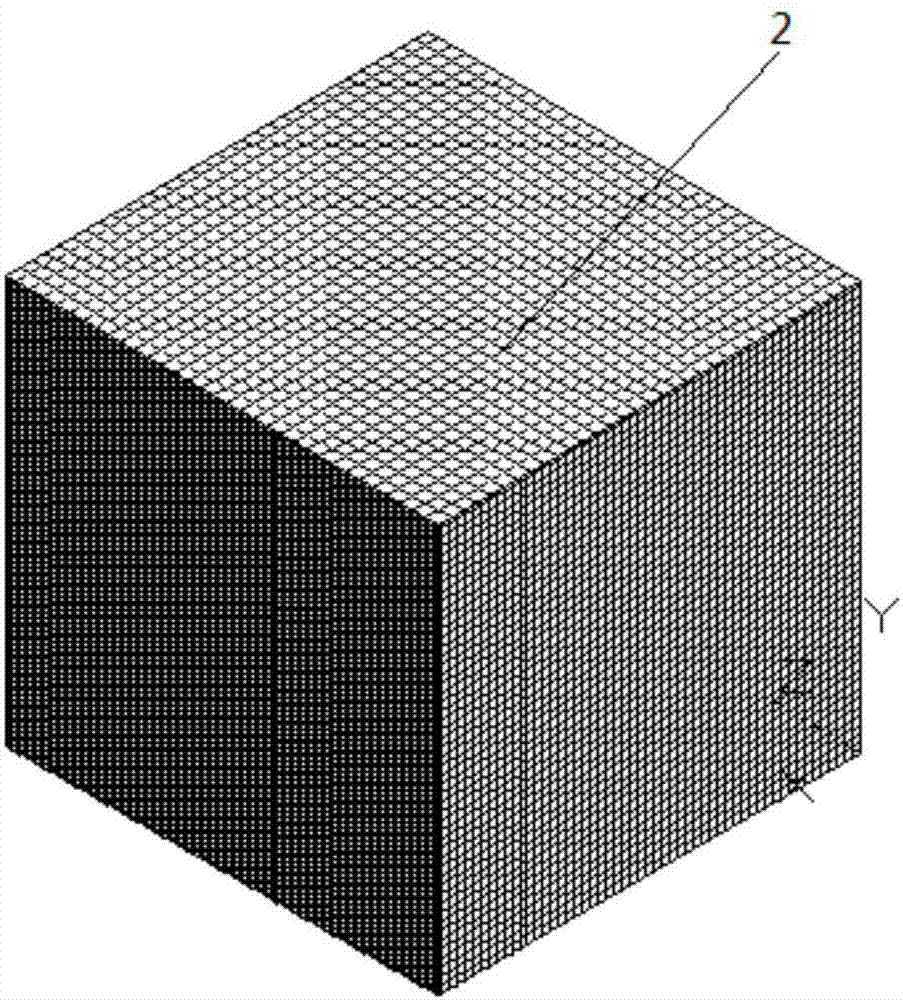

[0024] Such as Figure 1-Figure 5 As shown, the embodiment of the present invention provides a secondary composite cavity water storage brick made of recycled aggregate. The brick body includes an outer water-retaining layer body 3 whose only upper surface is an open surface, and a water-storage core body 2 and a moisture-retaining grass layer body 1 located inside the water-retaining layer body 3. When in use, the opening of the water-retaining layer body 3 Facing upward, in the length direction of the brick body, the moisture-retaining grass layer 1 is placed above the water storage core 2; the water storage core 2 includes raw materials: coarse aggregate, straw, Malan loess, natural auxiliary materials; the external The water-retaining layer 3 is prepared from fine aggregate concrete; the moisture-retaining grass-planting layer 1 is composed of san...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com