Thermometer vacuole positioning and heating mechanism

A heating mechanism and thermometer technology, applied in thermometers, thermometers based on material expansion/contraction, heat measurement, etc., can solve the problems of large differences in the length of bubble ends, large differences in bubble lengths, increased scrap rate, etc., and achieve an increase in yield , reduce consumption and improve sealing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Below in conjunction with embodiment, further illustrate the present invention.

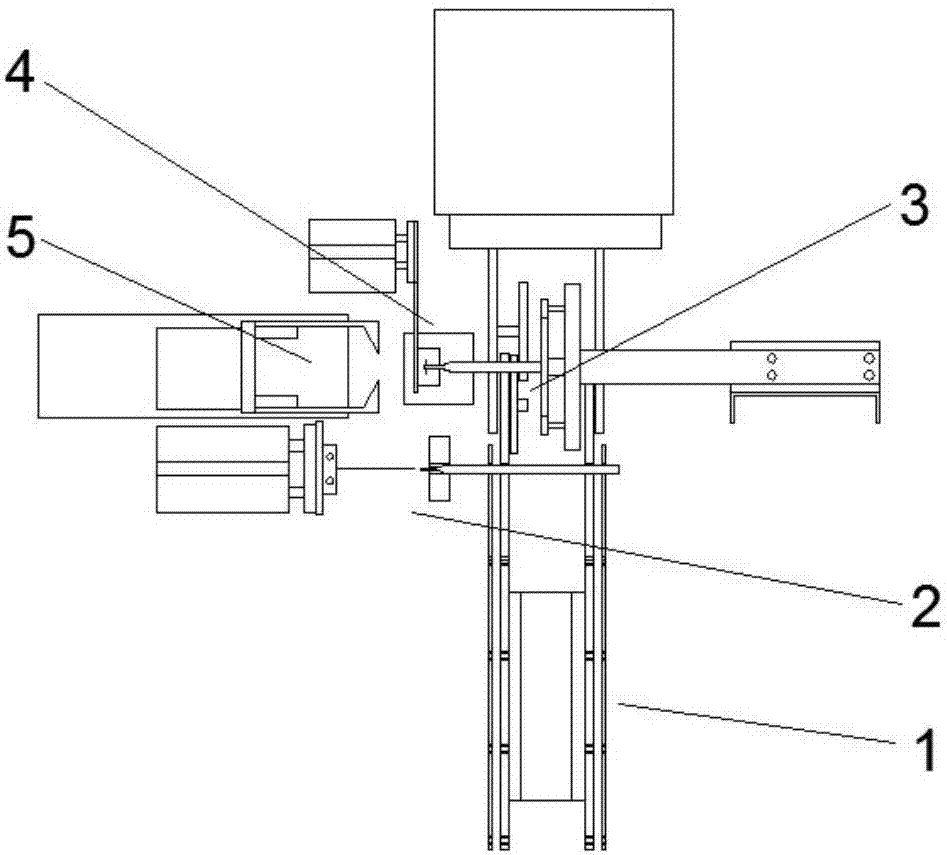

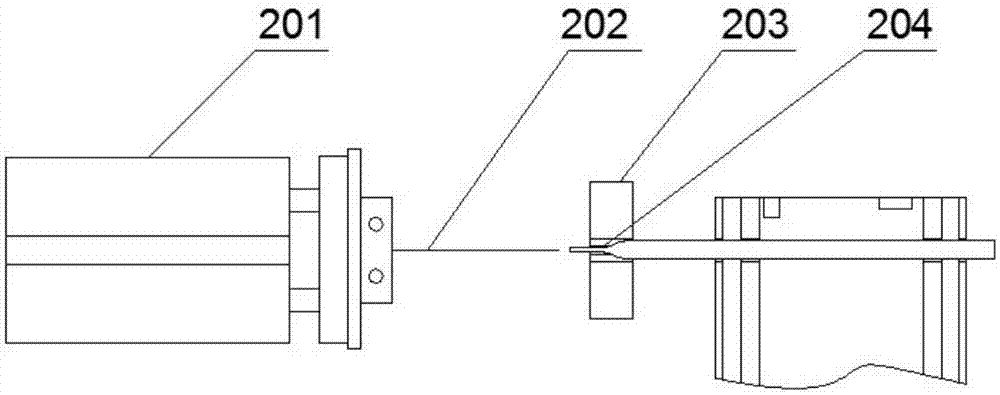

[0053] combine figure 1 It can be seen that a thermometer bubble positioning and heating mechanism of the present invention is composed of a conveying device 1, a heating device 4, and a bubble sealing device 5. The outside of the conveying device 1 is provided with a positioning device 2, and the rear of the positioning device 2 is provided with a heating device 4. , The bubble sealing device 5, the heating device 4, and the corresponding position of the bubble sealing device 5 are provided with a rotary driving device 3.

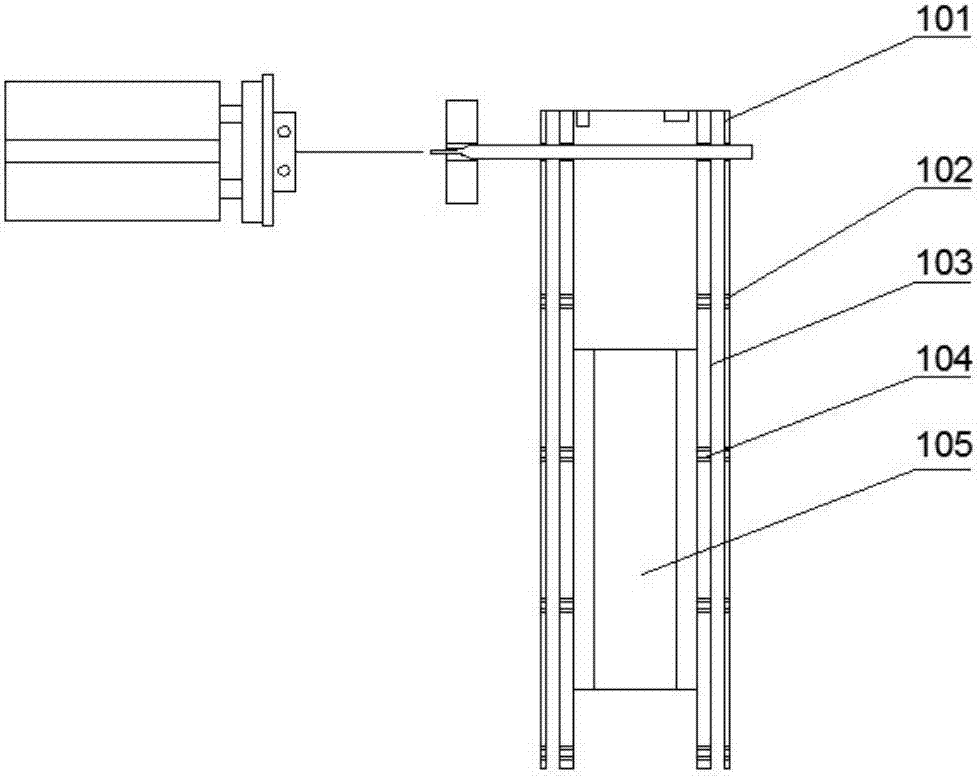

[0054] combine figure 2 It can be seen that the top of the side wall 101 of the conveying device 1 is provided with conveying fixing grooves 102 arranged at intervals, and the conveying fixing grooves 102 fix the thermometer.

[0055] The side wall 101 of the conveying device 1 is provided with a lifting propulsion seat 103, and the lifting propulsion seat 103 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com