Electric heating roller furnace structure optimization method

An optimization method and technology of electric heating rollers, applied in design optimization/simulation, electrical digital data processing, special data processing applications, etc., can solve the problems of long optimization design cycle, blind structure adjustment direction, inability to meet, etc., to ensure the furnace temperature The effect of uniformity, shortening the structure optimization cycle and saving design cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

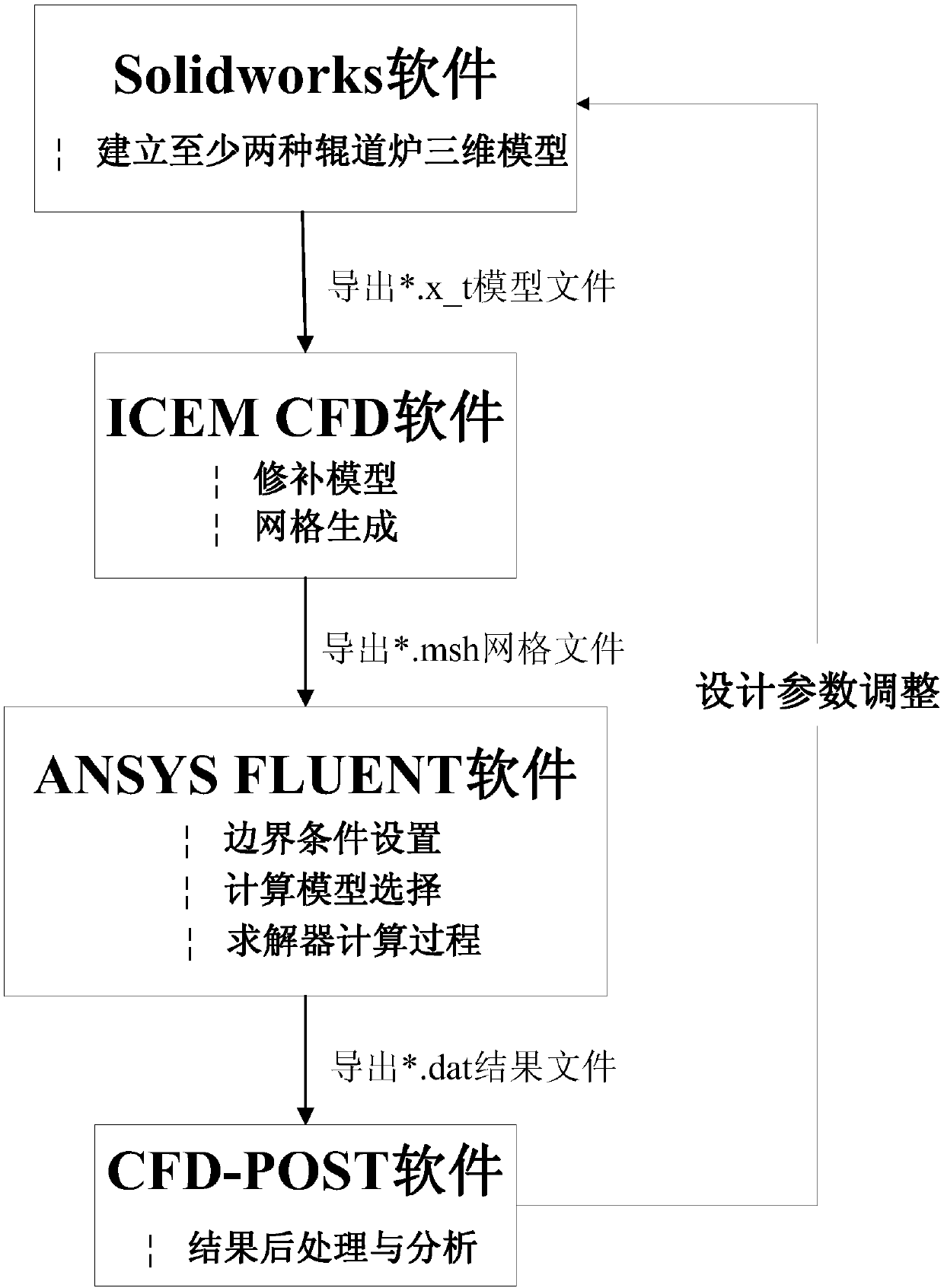

Method used

Image

Examples

Embodiment 1

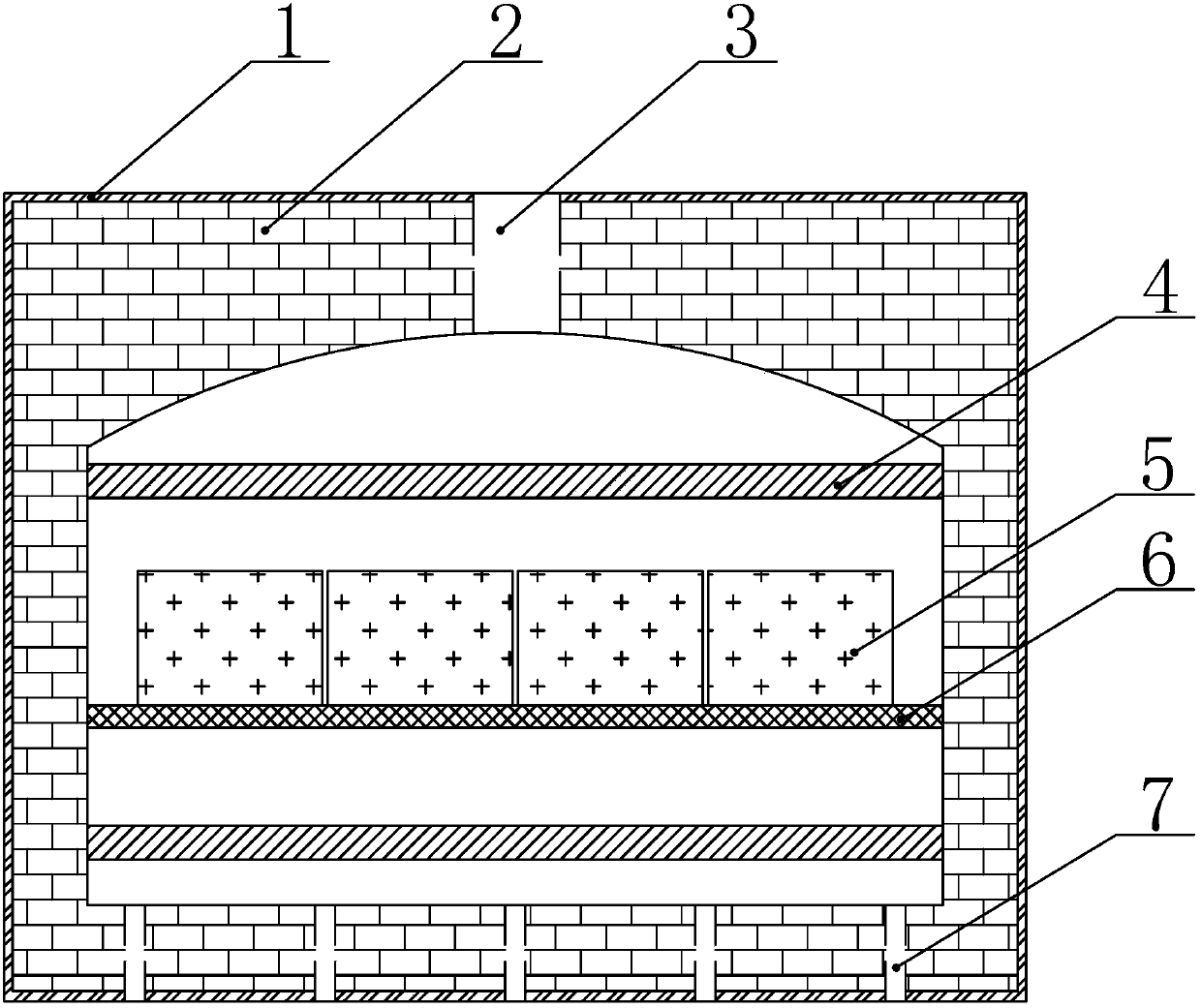

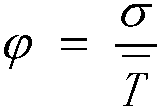

[0039] In step S01, the structural optimization of the electrothermal roller furnace is realized by adjusting the furnace width-to-height ratio in the design parameters, specifically: two types of roller furnace models are established, and the furnace width-to-height ratio of the original structure model is: 2:1 , while the furnace width-to-height ratio of the new model 1 is 1.5:1, and other design parameters such as the furnace width-to-height ratio are the same. Execute steps S02 to S04. In step S04, the dimensionless temperature difference coefficients of the hearth center section of the two roller furnace models are obtained As shown in Table 1 below:

[0040] Table 1:

[0041] Model

[0042] According to the comparison results, the new model with a smaller temperature difference coefficient is taken as the optimal solution, and then the furnace width-to-height ratio is adjusted at least once for the optimal solution, and then steps S02 to S04 are repeated to c...

Embodiment 2

[0044] The difference between this embodiment and the first embodiment is that the structural optimization of the electric roller furnace is realized by adjusting the spacing of the silicon carbide rods in the design parameters, and other design parameters such as the width and height of the furnace are not adjusted.

[0045] Specifically, in step S01, three types of roller hearth furnace models are established, wherein the distance between the SiC rods of the original structure model is 250 mm, the distance between the SiC rods of the new model 2 is 220 mm, and the distance of the SiC rods of the new model 3 is 280 mm. Then execute steps S02-S04. In step S04, calculate the dimensionless temperature difference coefficients of the hearth center sections of the three roller furnace models The calculation results are shown in Table 2 below:

[0046] Table 2:

[0047] Model

SiC rod spacing (mm)

temperature difference coefficient

original structure model

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com