Circuit board and circuit board manufacturing method

A circuit board and inductor technology, which is applied in the fields of printed circuit manufacturing, printed circuit, printed circuit, etc., can solve the problems of increased noise in the final product, large solder paste resistance, and low production efficiency, so as to increase the resonance frequency and shorten the process , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The circuit board and the manufacturing method of the circuit board provided by the present invention will be described in detail below in conjunction with specific implementation methods.

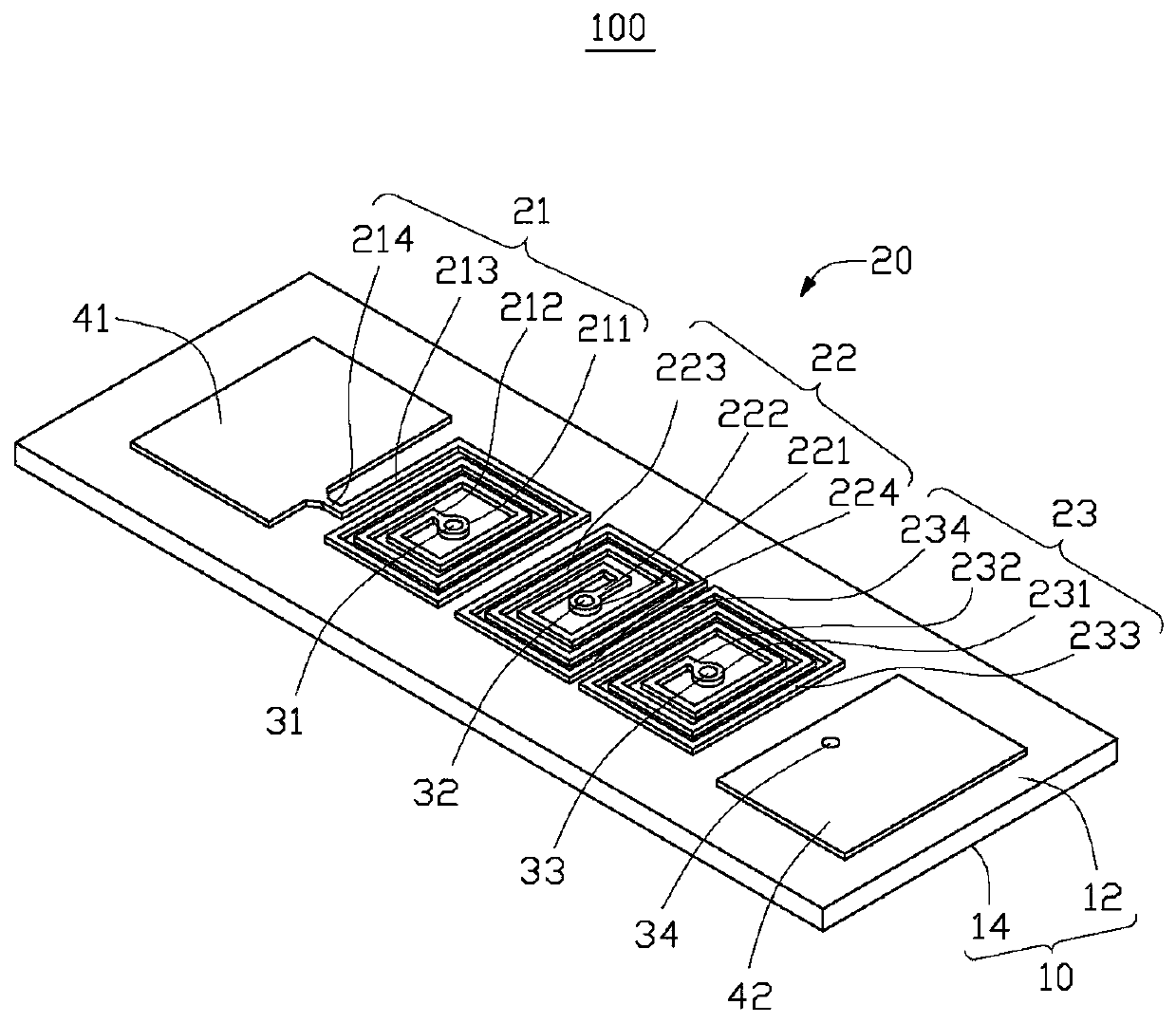

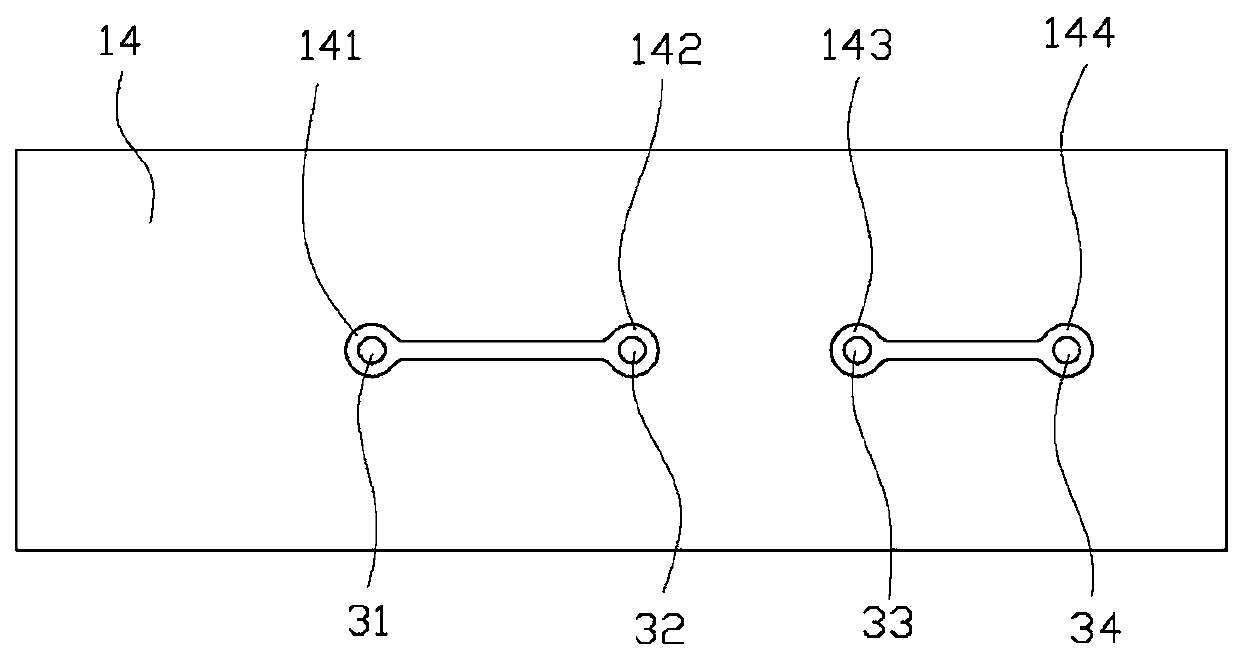

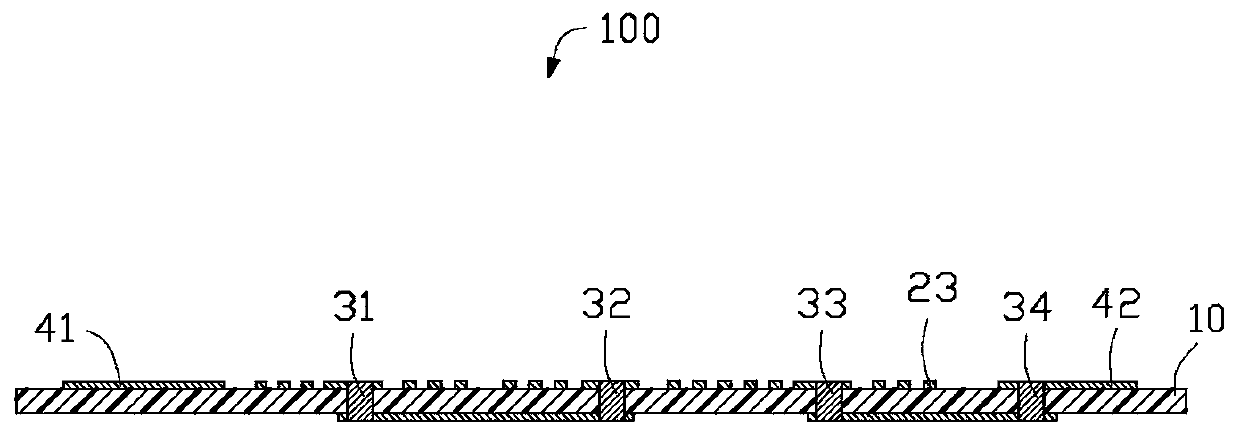

[0015] see figure 1 , the circuit board 100 provided by the embodiment of the present invention. The circuit board 100 includes a base 10 . The substrate 10 includes a first surface 12 and a second surface 14 . The first surface 12 and the second surface 14 are located on opposite sides of the base 10 . The first surface is provided with an inductor unit 20 .

[0016] The inductance unit 20 includes a first inductance coil 21 , a second inductance coil 22 and a third inductance coil 23 . In this embodiment, the first induction coil 21 , the second induction coil 22 and the third induction coil 23 are arranged side by side on the first surface 12 . Wherein, the first induction coil 21 is spaced apart from the second induction coil 22 , and the second induction coil 22 is electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com