Pure electric commercial vehicle power assembly suspension system and assembling method thereof

A powertrain and suspension system technology, applied in the direction of electric power devices, power devices, control devices, etc., can solve problems such as poor vibration isolation effect, achieve good vibration isolation effect, reduce the number, and have strong support and vibration reduction effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

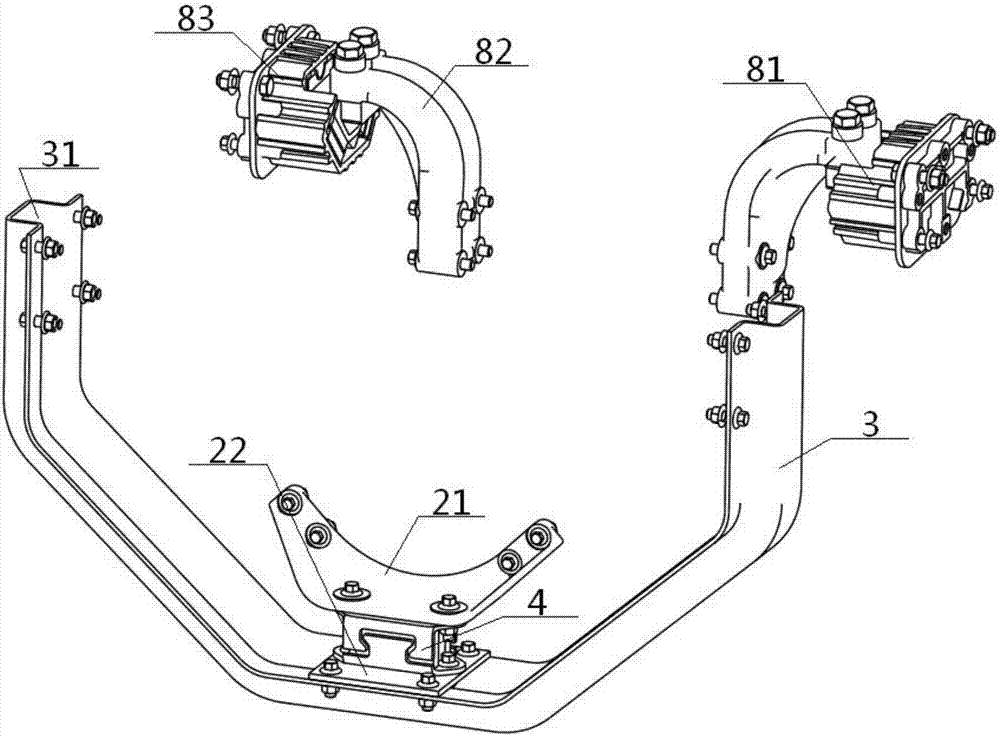

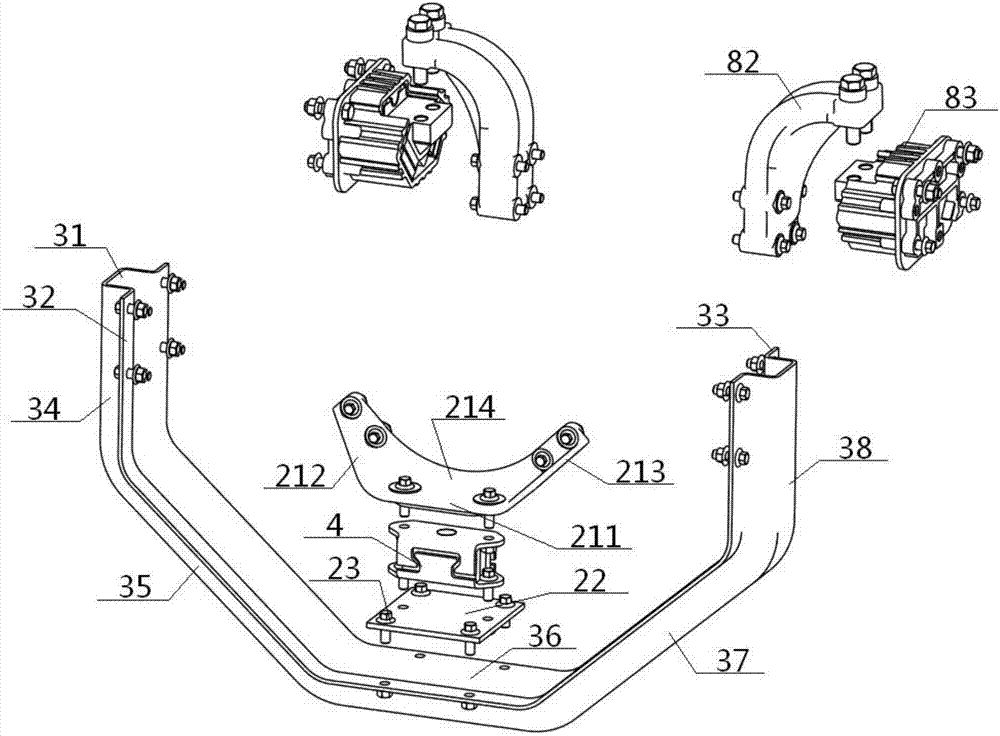

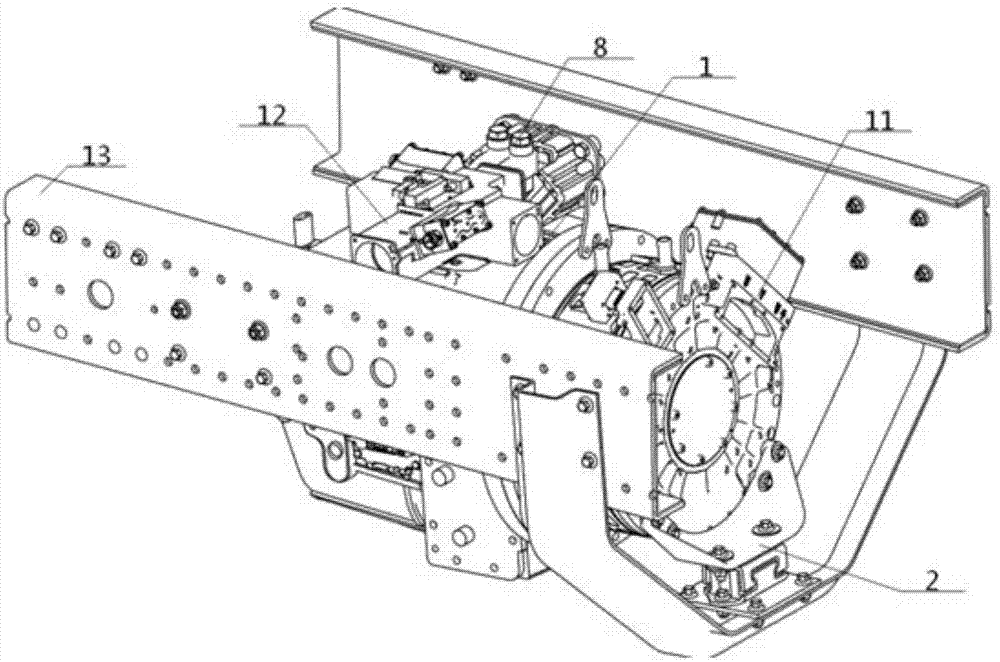

[0065] see Figure 1 to Figure 10, a powertrain suspension system for a pure electric commercial vehicle, comprising a front suspension assembly 2 and a rear suspension assembly 8, the front suspension assembly 2 connects the front end of the powertrain 1 to the frame longitudinal beam 13 The rear suspension assembly 8 connects the rear end of the power assembly 1 with the frame rail 13; the front suspension assembly 2 includes a front suspension bracket 21, a front suspension cushion assembly 4 and the front suspension bracket 3, the front end of the power assembly 1 is connected with the middle part of the front suspension bracket 3 after passing through the front suspension bracket 21 and the front suspension cushion assembly 4 successively, and the front suspension bracket The left and right ends of the frame 3 are connected with the vehicle frame longitudinal beam 13 (such as the outer covering surface of the vehicle frame longitudinal beam 13), the left and right ends of...

Embodiment 2

[0068] Basic content is the same as embodiment 1, the difference is:

[0069] The front suspension bracket 21 includes a front bracket base plate 211, a front bracket left side plate 212, a front bracket right side plate 213 and a U-shaped front bracket rear plate 214, the middle part of the front bracket base plate 211 and the front bracket located below it The suspension cushion assembly 4 is connected, the rear end of the front bracket bottom plate 211 is vertically connected with the bottom end of the middle part of the front bracket rear plate 214, the left and right ends of the front bracket rear plate 214 are connected with the front end of the power assembly 1, The space formed by the interconnection of the front support rear plate 214 and the front support bottom plate 211 is inlaid with the front support left side plate 212 and the front support right side plate 213.

Embodiment 3

[0071] Basic content is the same as embodiment 1, the difference is:

[0072] The front suspension cushion assembly 4 includes an upper frame 5, a rubber body 6 and a lower frame 7 that are connected sequentially from top to bottom and are vulcanized as one. The upper frame 5 includes an upper top plate 51 and its inner and outer sides. Connected upper inner flange 52 and upper outer flange 53, the lower frame 7 includes a lower bottom plate 71 and a lower inner flange 72 connected to its inner and outer sides, a lower outer flange 73, and an upper inner flange 52 , the lower inner flange 72 is on the same plane, the upper outer flange 53 and the lower outer flange 73 are on the same plane, and the rubber body 6 is located on the plane where the upper inner flange 52, the lower inner flange 72 are located and the upper outer flange Between the planes where the flanging 53 and the lower outer flanging 73 are located; the top surface of the upper top plate 51 is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com